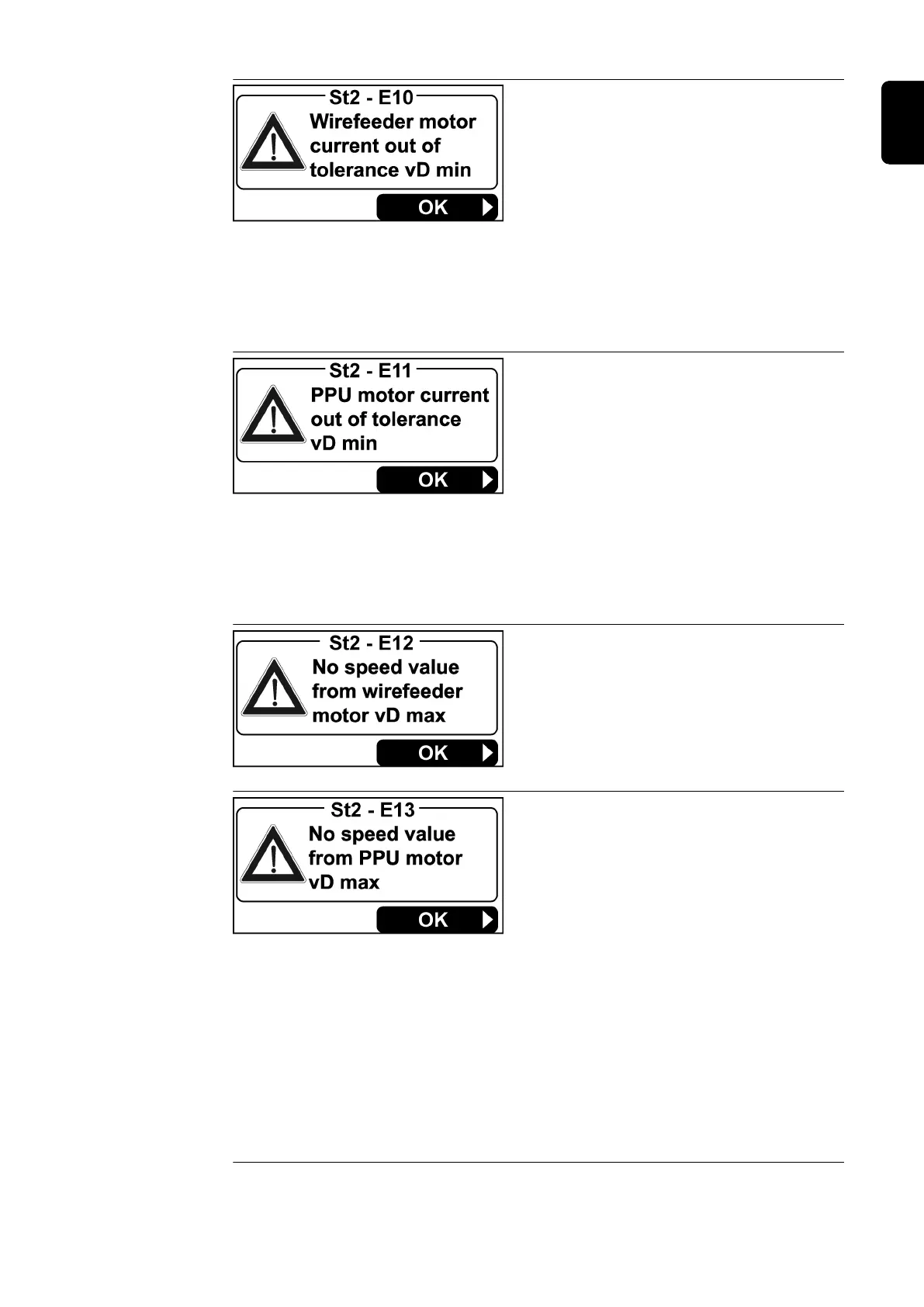

Cause: At minimum wire feed speed,

the motor current of the wire-

feed unit motor is outside the

permitted range. Possible reas-

ons are disengaged wire-feed

unit motors or wire feed prob-

lems.

Remedy: Engage the drive units of both wirefeeder motors, arrange the hosepack

in as straight a line as possible; check the inner liner for kinks or soiling;

check the contact pressure on the 2-roller or 4-roller drive of the push-pull

unit.

Repeat the push-pull calibration. If the error message re-appears: Contact

After-Sales Service.

Cause: At minimum wire feed speed,

the motor current of the push-

pull unit is outside the permitted

range. Possible reasons are

disengaged wire-feed unit

motors or wire feed problems.

Remedy: Engage the drive units of both wirefeeder motors, arrange the hosepack

in as straight a line as possible; check the inner liner for kinks or soiling;

check the contact pressure on the 2-roller or 4-roller drive of the push-pull

unit.

Repeat the push-pull calibration. If the error message re-appears: Contact

After-Sales Service.

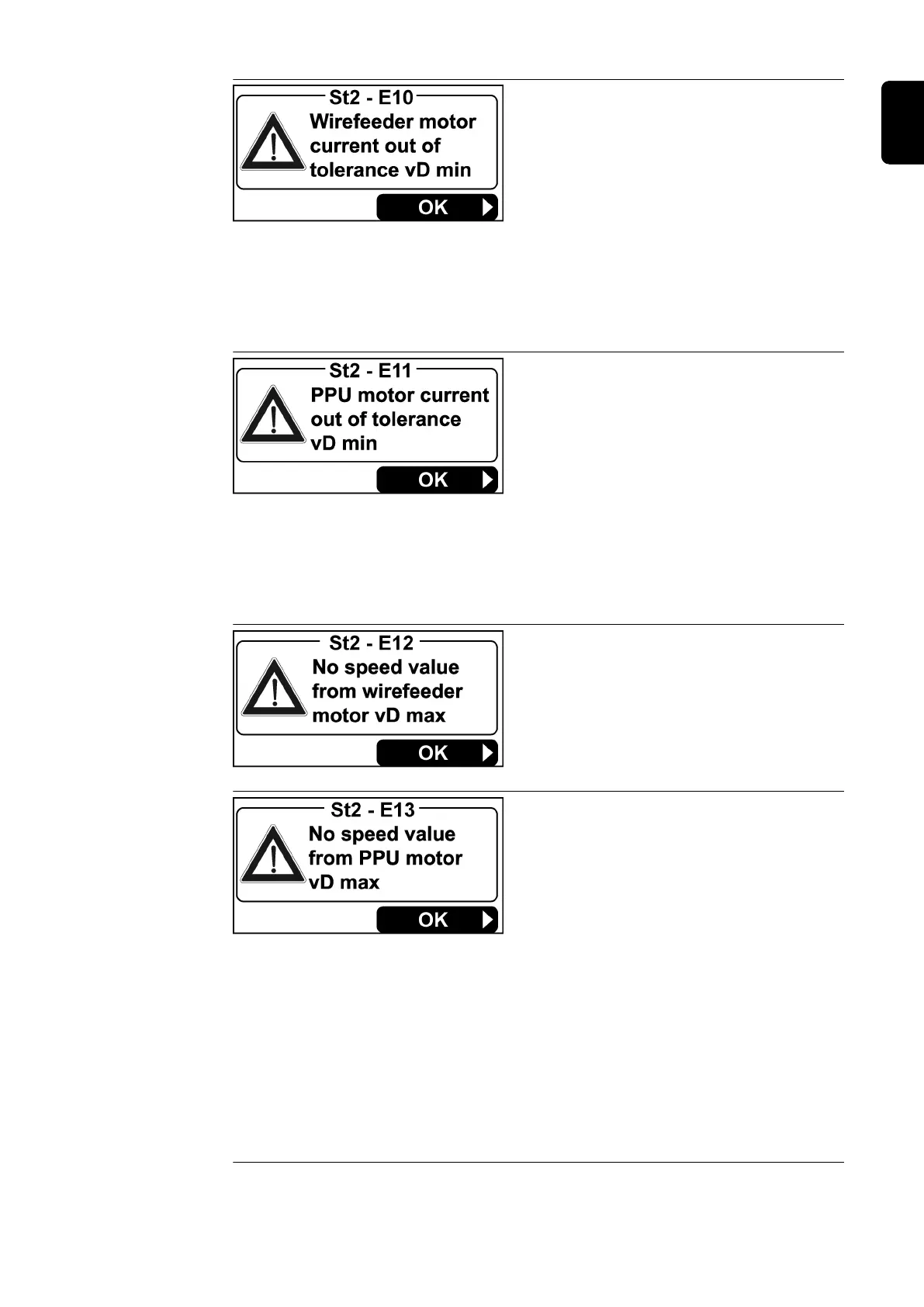

Cause: At maximum wire feed speed,

the wire-feed motor does not

deliver any actual rotational

speed value.

Remedy: Repeat the push-pull calibra-

tion. If the error message re-

appears: Contact After-Sales

Service.

Cause: At maximum wire feed speed,

the motor of the push-pull unit

does not deliver any actual rota-

tional speed value.

Remedy: Repeat the push-pull calibra-

tion. If the error message re-

appears: Contact After-Sales

Service, faulty actual value pick-

up St2 | E 14

Cause: At maximum wire feed speed, the motor current of the wire-feed unit

motor is outside the permitted range. Possible reasons are disengaged

wire-feed unit motors or wire feed problems.

Remedy: Engage the drive units of both wirefeeder motors, arrange the hosepack

in as straight a line as possible; check the inner liner for kinks or soiling;

check the contact pressure on the 2-roller or 4-roller drive of the push-pull

unit.

Repeat the push-pull calibration. If the error message re-appears: Contact

After-Sales Service.

131

EN

Loading...

Loading...