6-14

[ 1.2 ] 10%ED model

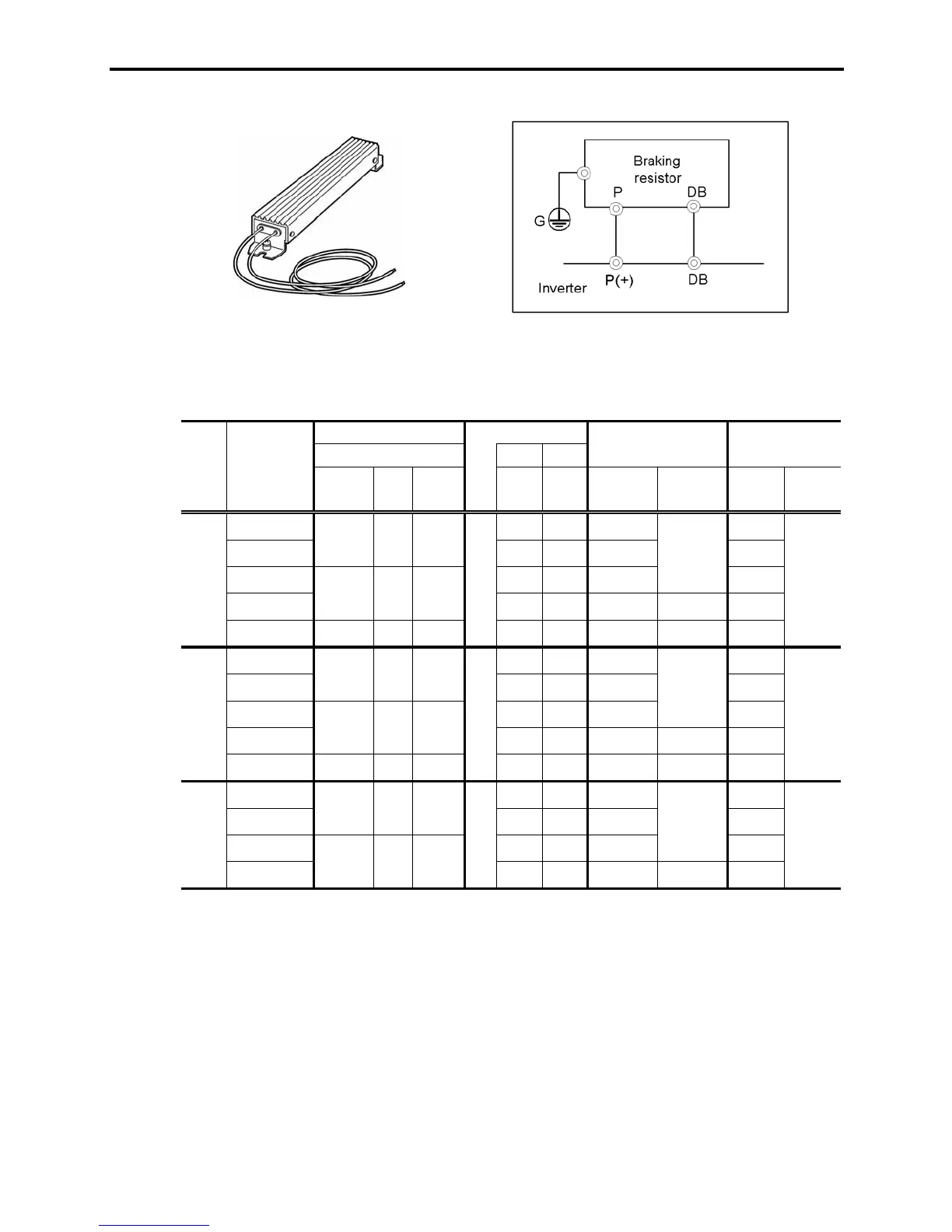

Figure 6.7 Braking Resistor (10 %ED Model) and Connection Example

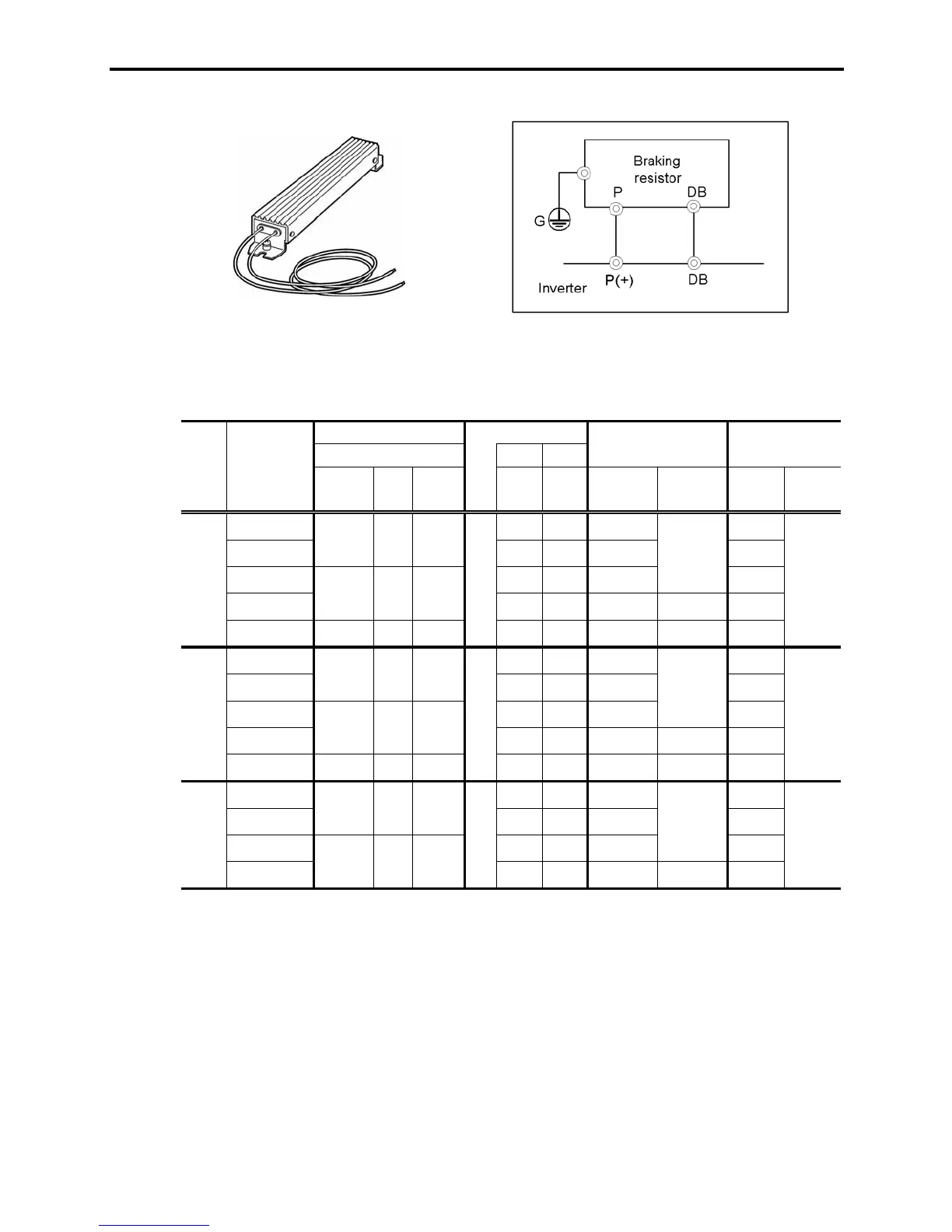

Table 6.8 Braking Resistor (10 %ED Model)

Option

Braking resistor 50 Hz 60 Hz

FRNF50C1

-2U

35.6

(4.02)

29.4

(3.32)

90.027

FRN001C1

-2U

67.0

(7.57)

55.3

(6.25)

17 0.050

FRN002C1

-2U

133

(15.0)

110

(12.4)

34 0.101

FRN003C1

-2U

195

(22.0)

161

(18.2)

33 30 0.148

FRN005C1

-2U DB3.7-2C 1 33

328

(37.1)

270

(30.5)

37 20 0.248

FRNF50C1-4U

35.6

(4.02)

29.4

(3.32)

90.027

FRN001C1

-4U

67.0

(7.57)

55.3

(6.25)

17 0.050

FRN002C1

-4U

133

(15.0)

110

(12.4)

34 0.101

FRN003C1-4U

195

(22.0)

161

(18.2)

33 30 0.148

FRN005C1

-4U DB3.7-4C 1 130

328

(37.1)

270

(30.5)

37 20 0.248

FRNF50C1

-7U

35.6

(4.02)

29.4

(3.32)

90.027

FRN001C1

-7U

67.0

(7.57)

55.3

(6.25)

17 0.050

FRN002C1

-7U

133

(15.0)

110

(12.4)

34 0.501

FRN003C1

-7U

195

(22.0)

161

(18.2)

33 30 0.248

Power

supply

voltage

Inverter type

Max. braking torque (%)

Continuous braking (

100%

torque conversion value)

lb-in

(N·m)

lb-in

(N·m)

Repetitive braking

(100 sec or less cycle)

Type Q'ty

Resistance

(

:

)

Discharging

capability

(kWs)

Braking time

(s)

Average

loss

(HP)

Duty cycle

(%ED)

Three-

phase

230 V

DB0.75-2C 1 100

150

DB2.2-2C 1 40

Three-

phase

460 V

DB0.75-4C 1 200

150

DB2.2-4C 1 160

Single-

phase

230 V

DB0.75-2C 1 100

150

DB2.2-2C 1 40

45

45

45

10

10

10

Notes: 1) A box (

) in the above table replaces S or E depending on enclosure.

The 10 %ED braking resistor does not support overheating detection or warning output, so an electronic

thermal overload relay needs to be set up using function codes F50 and F51 to protect the braking resistor

from overheating.

Loading...

Loading...