9-2

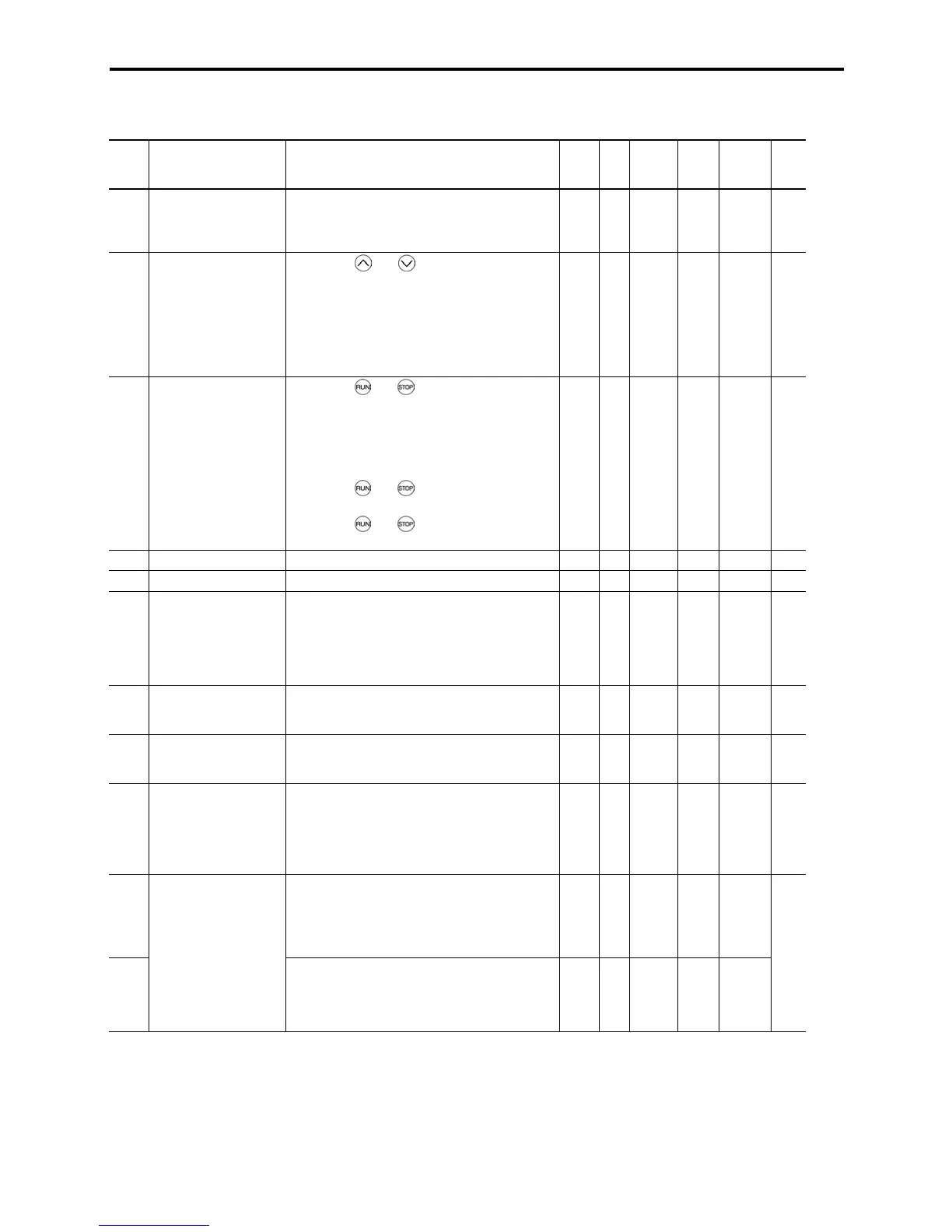

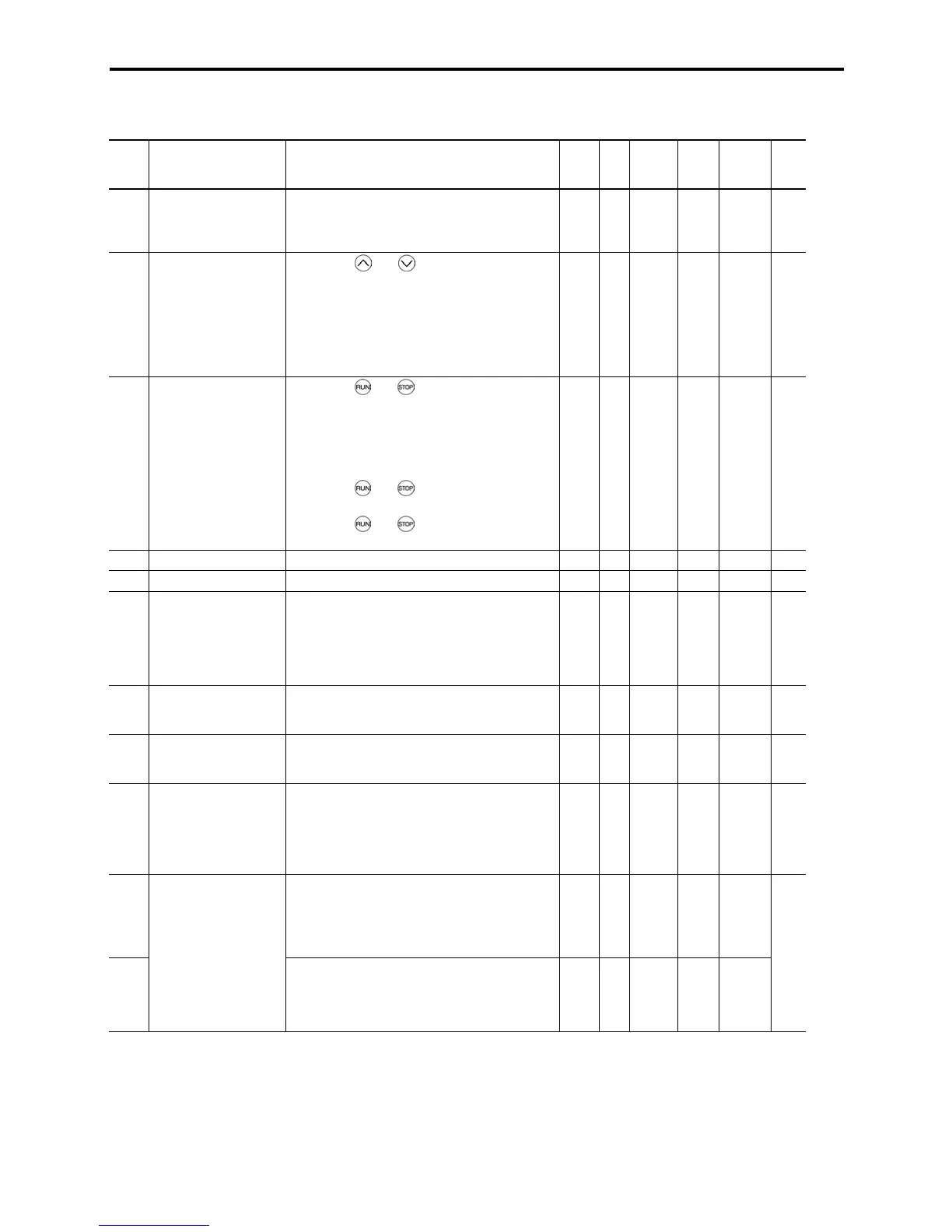

The following tables list the function codes available for the FRENIC-Mini series of inverters.

F codes: Fundamental Functions

Code Name Data setting range

Incre-

ment

Unit

Change

when

running

Data

copy

Default

setting

Refer

to:

F00 Data Protection 0: Disable data protection

(Function code data can be edited.)

1: Enable data protection

(Function code data cannot be edited.)

— — Y N 0 9-12

F01 Frequency Command 1

0: Enable

and keys on the built-in

keypad

1: Enable the voltage input to terminal [12]

2: Enable the current input to terminal [C1]

3: Enable the sum of voltage and current inputs

to terminals [12] and [C1]

4: Enable the built-in potentiometer (POT)

— — N Y 4 9-12

F02

Running/Stopping and

Rotational Direction

0: Enable

and keys on the built-in

keypad to run and stop motor

(The (FWD) or (REV) command should be

ON for forward or reverse rotation.)

1: Enable the external signal command (FWD)

or (REV) command to run motor

2: Enable

and keys on the built-in

keypad to run/stop motor forward

3: Enable

and keys on the built-in

keypad to run/stop motor reverse

— — N Y 2 9-13

F03 Maximum Frequency 25.0 to 400.0 0.1 Hz N Y 60.0 9-14

F04 Base Frequency 25.0 to 400.0 0.1 Hz N Y 60.0 9-15

F05 Rated Voltage (at Base

Frequency)

0: Output a voltage in line with

variance in input voltage

80 to 240: Output a voltage AVR-controlled *

2

(Note 1)

160 to 500: Output a voltage AVR-controlled *

2

(Note 2)

1 V N Y2 230

460

9-15

F07 Acceleration Time 1 0.00 to 3600

Note: Acceleration time is ignored at 0.00.

(External gradual acceleration pattern)

0.01 s Y Y 6.00 9-17

F08 Deceleration Time 1 0.00 to 3600

Note: Deceleration time is ignored at 0.00.

(External gradual deceleration pattern)

0.01 s Y Y 6.00 9-17

F09 Torque Boost 0.0 to 20.0

(The set voltage at base frequency for F05 is

100%.)

Note: This setting is effective for auto torque

boost/auto energy saving operations specified

by function code F37 (= 0, 1, 3, or 4).

0.1 % Y Y Fuji's *

1

standard

torque

boost

9-17

F10 Electronic Thermal

Overload for Motor

Protection

(Select motor

characteristics)

1: For general-purpose motors with built-in

self-cooling fan

2: For inverter-driven motors or high-speed

motors with forced-ventilation fan

— — Y Y 1

F11 (Overload detection

level)

0.00 (Disable)

1 to 135% of rated current (allowable continuos

load current) of the inverter

0.01 A Y Y

1

Y2

Nominal

*

1

rated

current of

Fuji

standard

motor

9-18

*

1

"Fuji's standard torque boost," "Nominal rated current of Fuji standard motor," and "Nominal rated capacity of Fuji standard motor" differ

depending upon the rated input voltage and rated capacity. Refer to Table 9.1 "Fuji Standard Motor Parameters" on page 9-11.

*

2

AVR: Automatic Voltage Regulator

(Note 1) For the three-phase 230 V and single-phase 230 V

(Note 2) For the three-phase 460 V

Loading...

Loading...