9-18

F10

Electronic Thermal Overload (for motor protection)

(Select motor characteristics)

F11 Electronic Thermal Overload (Overload detection level)

F12 Electronic Thermal Overload (Thermal time constant)

F10 through F12 set the thermal characteristics of the motor for its electronic thermal overload

protection that is used to detect overload conditions of the motor inside the inverter.

Thermal characteristics of the motor specified by F10 and F12 are also used for the

overload early warning. Even if you need only the overload early warning, set these

characteristics data to these function codes. To disable the electronic thermal motor

overload protection, set data of F11 to "0.00."

Motor characteristics (F10)㩷

F10 selects the cooling mechanism of the motor--built-in cooling fan or externally powered

forced-ventilation fan.

Data for F10 Function

1

For general-purpose motors with built-in self-cooling fan

(The cooling effect will decrease in low frequency operation.)

2

For inverter-driven motors or high-speed motors with forced-ventilation fan

(The cooling effect will be kept constant regardless of the output frequency.)

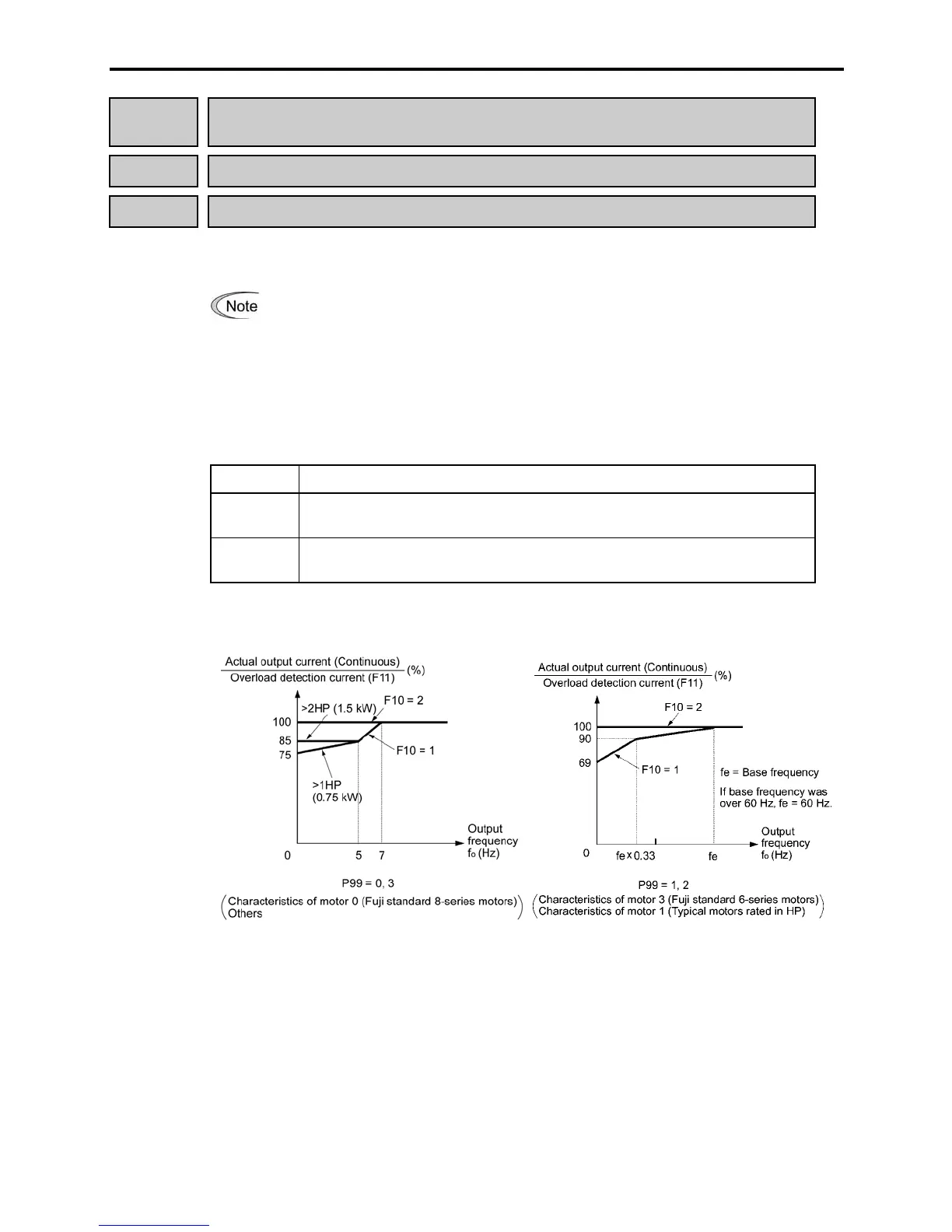

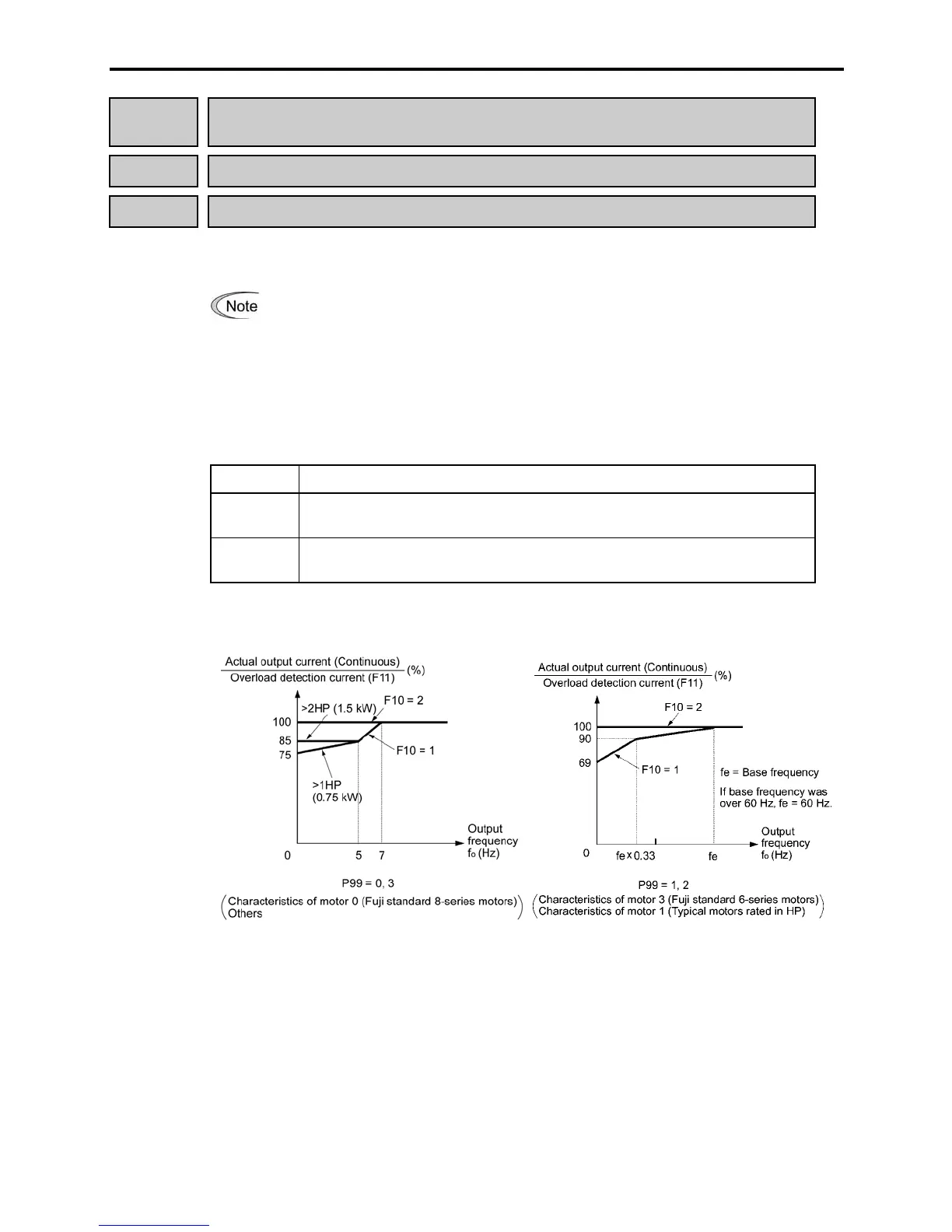

The figures below illustrate the cooling characteristics for the motor selected by function code

P99 (Motor selection).

Cooling Characteristics of Motors

Overload detection current (F11)

F11 specifies the operation level of the electronic thermal motor overload protection that

detects an overload condition.

- Data setting range: 1 to 135% of the rated current (allowable continuous drive current) of the

inverter

- In general, set the rated current of the motor when driven at base frequency to F11, that is, 1.0

to 1.1 multiple of the rated current of motor (P03).

- To disable the electronic thermal motor overload protection, set 0.00 to F11.

Loading...

Loading...