1-2

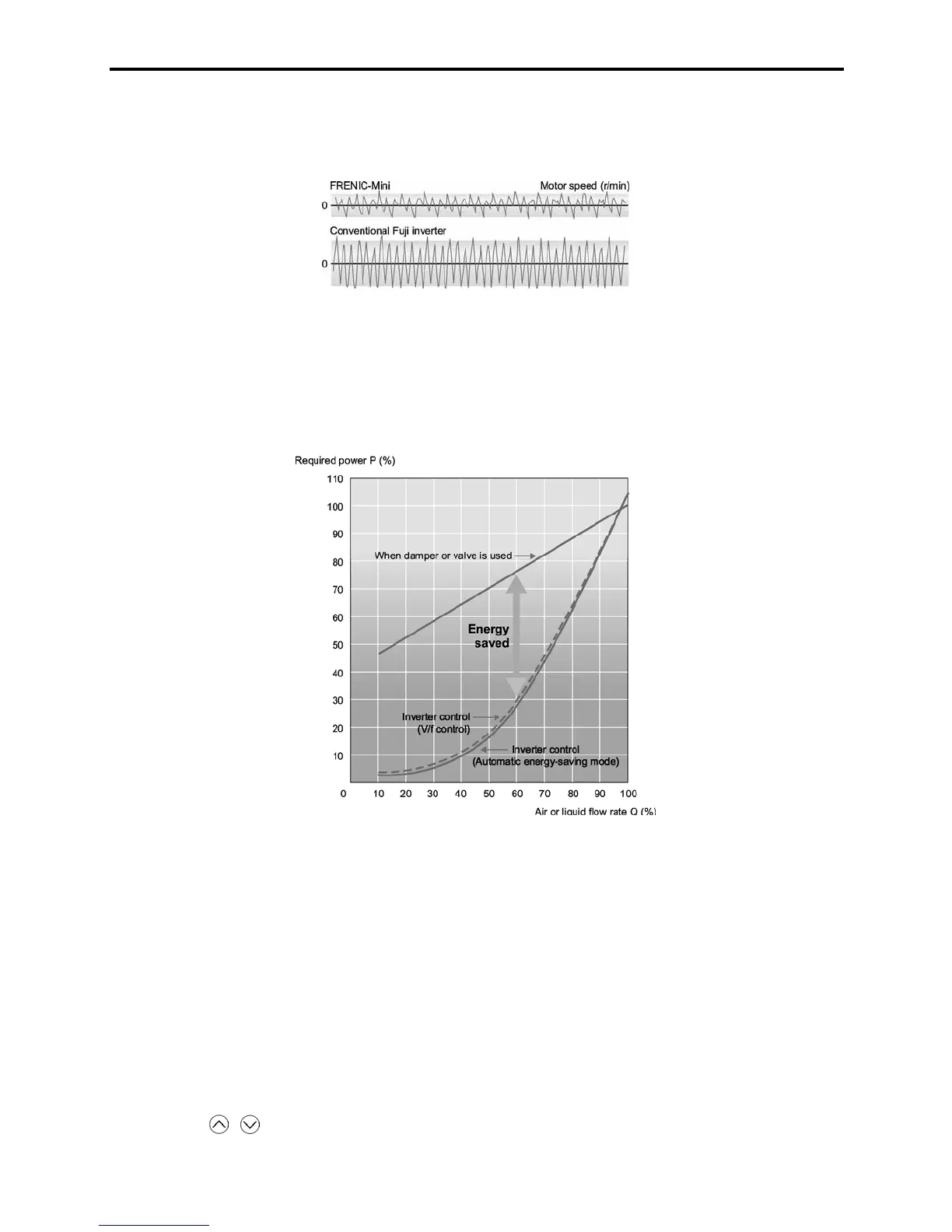

• Reduced motor instability at low speed

Fuji's unique control method improves voltage control performance and reduces motor instability at low

speed to about a half or under (at 1 Hz) compared with that of conventional inverters.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

Figure 1.5 Example of Instability Characteristics

Default functions for fans and pumps

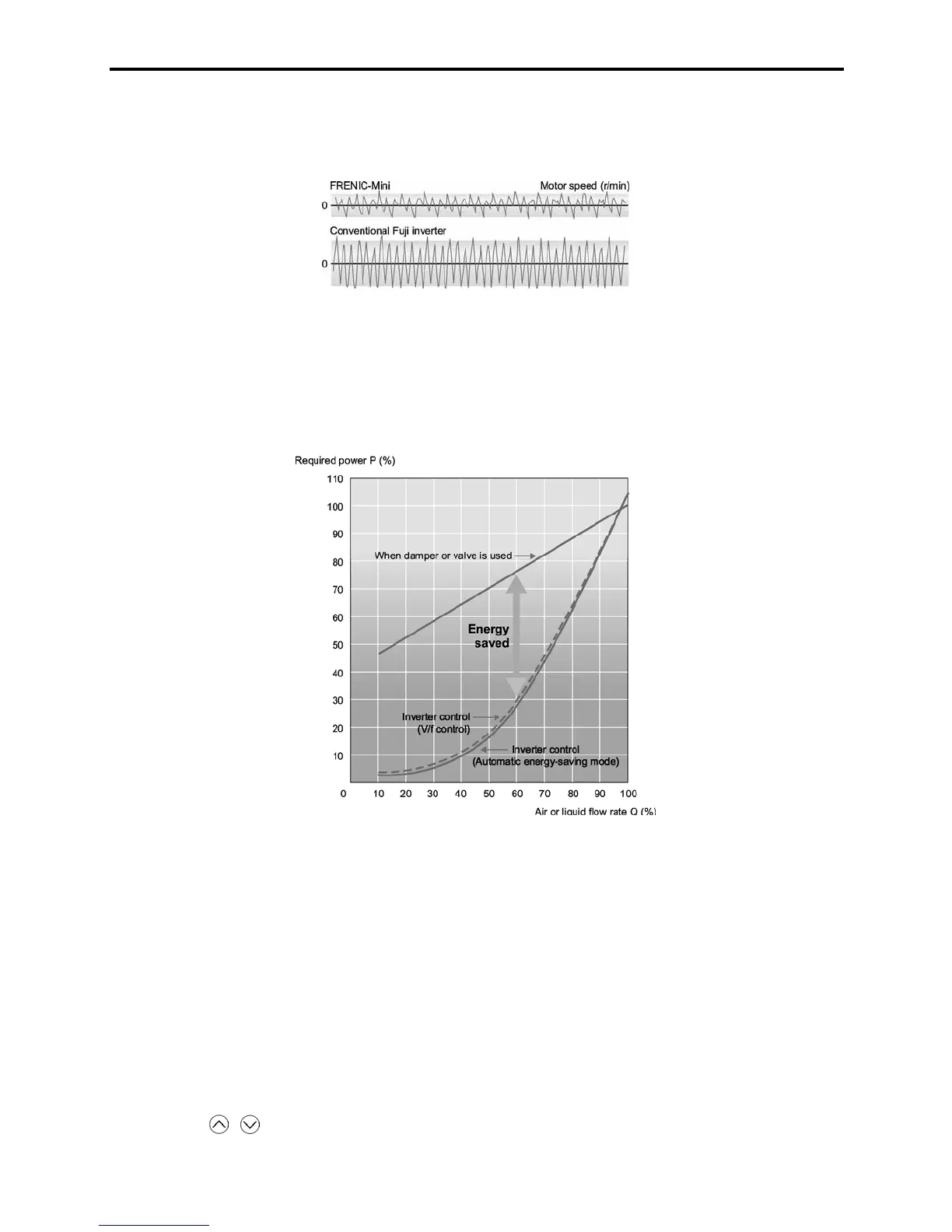

• Automatic energy-saving function provided as standard

To minimize the total loss (motor loss plus inverter loss), rather than just the motor loss as in the

predecessor models, FRENIC-Mini saves even more power when used with fans or pumps.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

* Energy savings vary depending on the motor characteristics.

Figure 1.6 Example of Energy Savings

• PID control function

Permits motor operation while controlling temperature, pressure, or flow rate without using an external

device such as a temperature regulator.

Refer to Chapter 4, Section 4.8 "PID Frequency Command Generator" for details.

• Cooling fan ON/OFF control function

The inverter's cooling fan can be turned off while the fan or pump is stopped for noise reduction and

energy savings.

The ideal functions to serve a multiplicity of needs for small-capacity inverters

• Compatible with a wide range of frequency settings

You can select the optimum frequency setting method that matches your machine or equipment via the

keypad (

/

keys or potentiometer), analog input (4 to 20 mA, 0 to 10 V, 0 to 5 V, 1 to 5 V), multistep

speed settings (0 to 7 steps) or via RS-485 communications. (Refer to Chapter 4, Section 4.2 "Drive

Frequency Command Generator" and Chapter 9, Section 9.2.1 "F codes" for details.)

Loading...

Loading...