Adequate fresh, clean air is necessary for safe and efcient combustion, and should be provided at

high and low level in accordance with BS 6644 1991 and IGE/UP/10 Part 1 Communication 1676.

Note:

a) Ensure there is adequate ventilation in the boiler room. Lack of ventilation will create a high temperature and

cause control lockout.

b) Where mechanical ventilation is provided for plantrooms, ensure positive pressurisation of the space is

always maintained - hazardous interlock with the boiler may be required for this purpose.

c) Do not store chemicals such as perclorethylene in the boiler house, the fumes may damage the boiler and

ue and cause the burner to lock out on ame failure. The ventilation requirements of these boilers are

dependant on the type of ue system used, and their heat input. All vents must be permanent with no means

of closing, and positioned to avoid accidental

obstructions by blocking or ooding.

Detail reference should be made to BS. 6644 for inputs between 70 kW and 1.8 MW (net).

In IE refer to the current edition of I.S.820:2000. The following notes are for general guidance only:

Dust contamination in the combustion air may cause blockage of the burner slots. Unless the boiler room

provides a dust free environment then direct connection of the air intake via ducting to clean outside

air should be used.

IMPORTANT NOTE: If combustion air is drawn from within the boiler room, ensure no dust or airborne debris can

be ingested into the appliance. Dusty concrete ooring should be sealed to reduce the presence of dust.

The temperature within a boiler room shall not exceed 25°C within 100 mm of the oor, 32°C at mid

height and 40°C within 100 mm of the ceiling.

Open Flued Installations

If ventilation is to be provided by means of permanent high and low vents communicating direct with

outside air, then reference can be made to the sizes below. For other ventilation options refer to BS.

6644. In IE refer to the current edition of I.S.820.

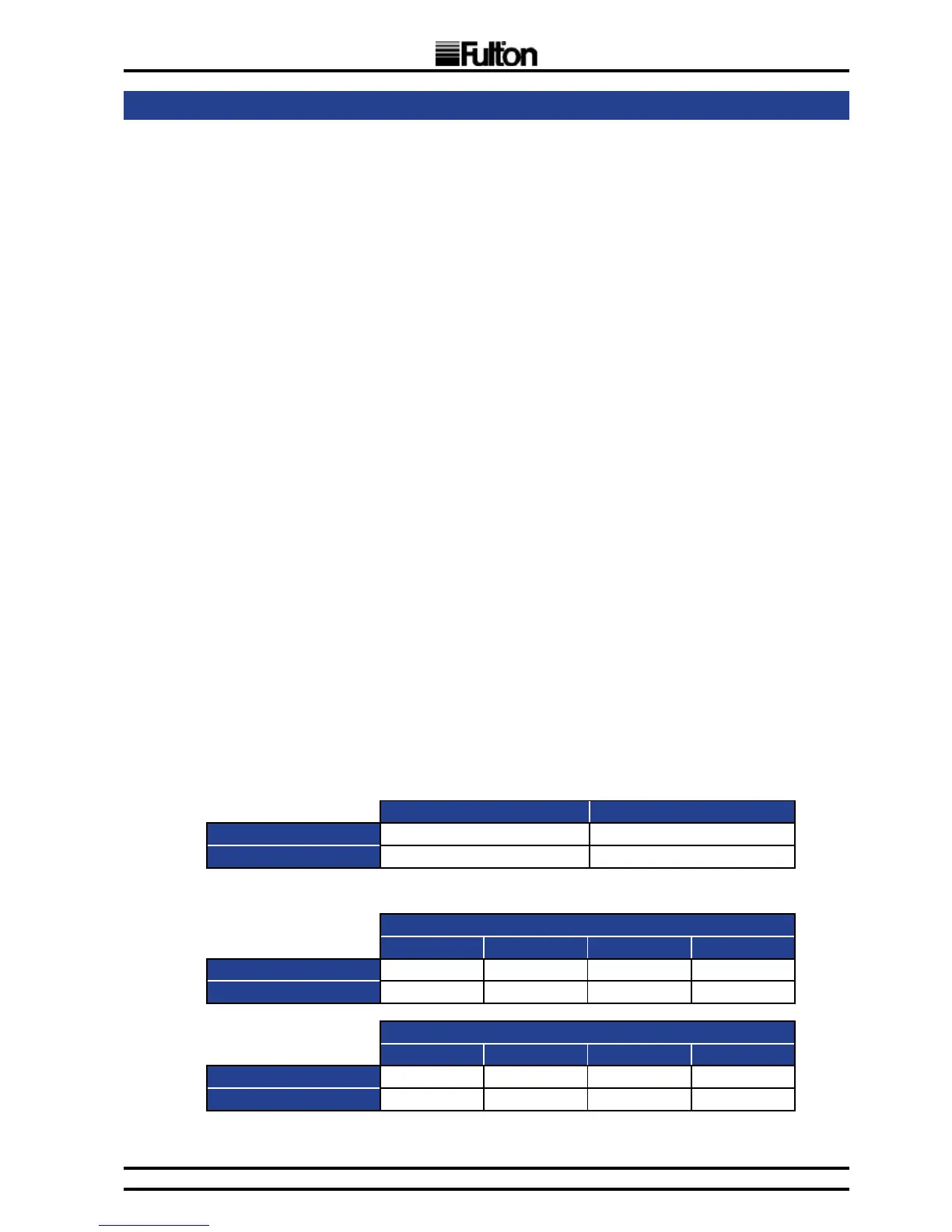

Required area (cm

2

) per kW of total rated input (net)

Note: Where a boiler installation is to operate in summer months (e.g. DHW), additional ventilation requirements

are stated within BS6644 if operating for more than 50% of the time.

Boiler Room Enclosure

Low Level (Inlet) 4 10

High Level (Outlet) 2 5

2.12

VENTILATION

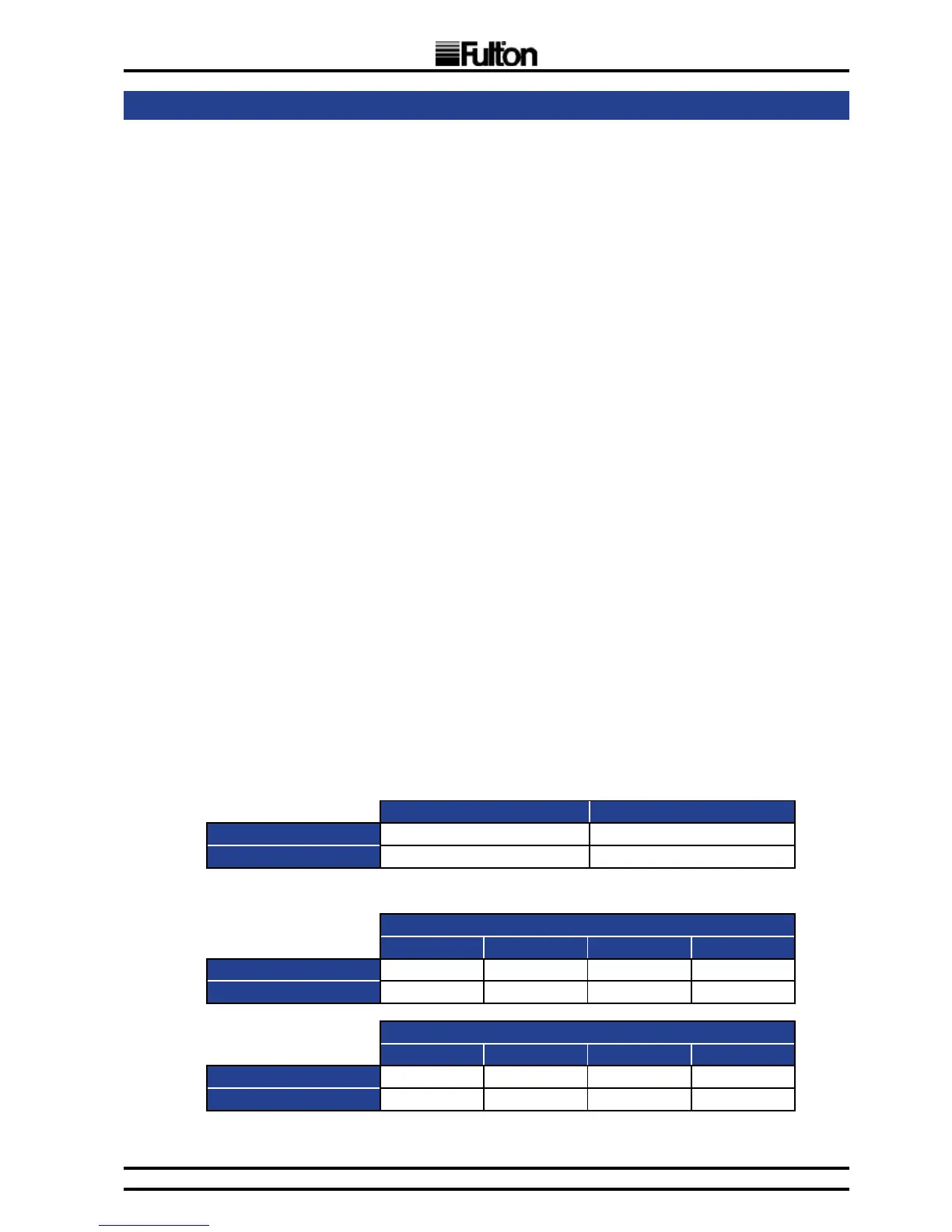

Required area (cm

2

)

Boiler Room

FHE-250 FHE-500 FHE-750 FHE-1000

Low Level (Inlet) 1020.4 2040.8 3061.2 4081.6

High Level (Outlet) 510.2 1020.4 1530.6 2040.8

Enclosure

FHE-250 FHE-500 FHE-750 FHE-1000

Low Level (Inlet) 2551 5102 7653 10204

High Level (Outlet) 1275.5 2551 3826.5 5102

Loading...

Loading...