FHE-250 MANUAL 09 2014 ISSUE 2

Note: Long Flues: It is recommended that a support bracket is tted at least every 1 m of ue length and a

bracket must be tted at every ue joint to ensure ue seal and alignment of ue.

WARNING

Care should also be taken in the selection of ue terminals as these tend to accentuate the formation

of a plume and could freeze in cold weather conditions.

WARNING

Care should be taken to ensure the specication of the chimney is suitable for the application by

reference to the manufacturers literature.

WARNING

Where single walled ues are used on the appliance, surface temperatures of the ue can reach

temperatures in excess of 80°C.

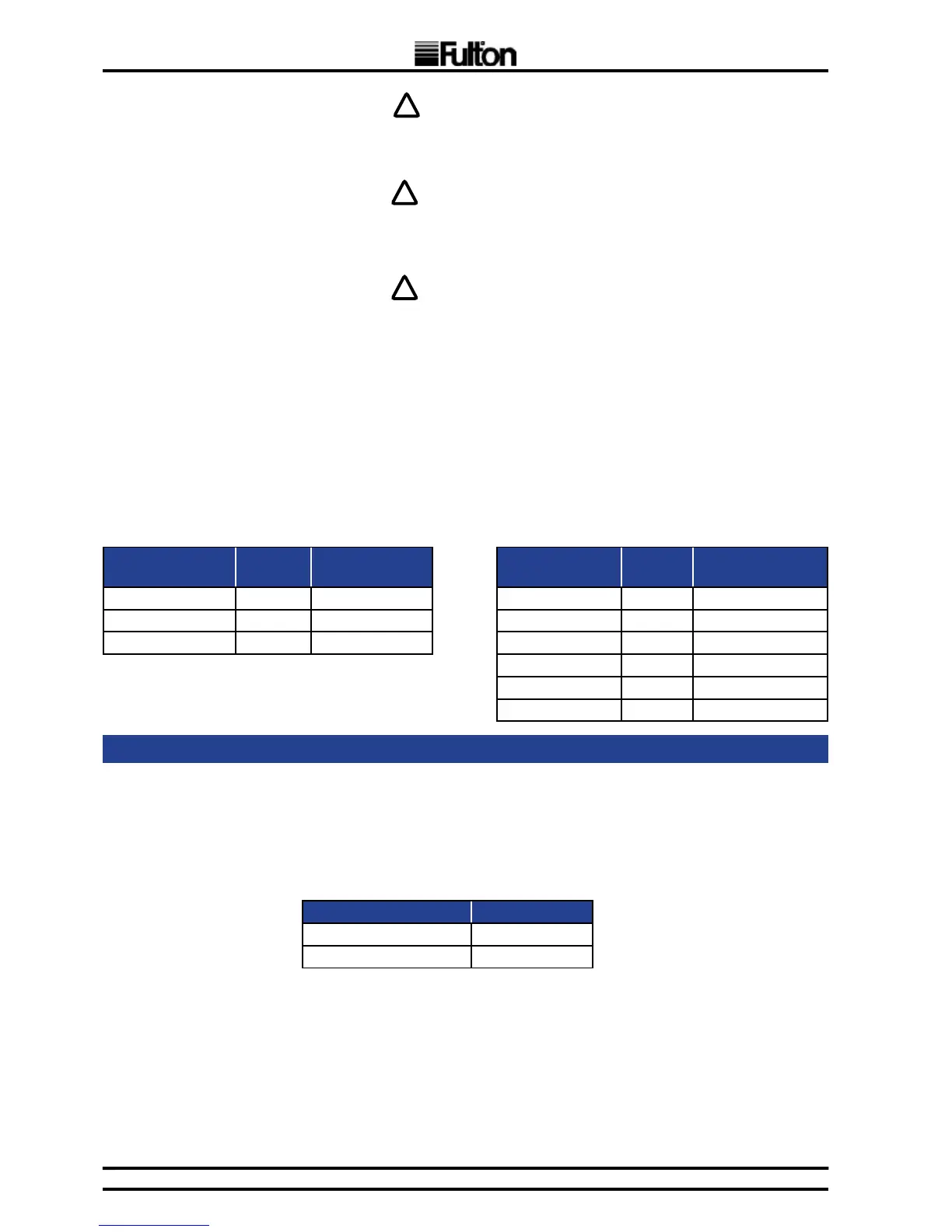

Flue/Exhaust Vent

Item

Size

(mm Ø)

Pressure Drop

(Pa)

1 m of Flue/Vent 150 0.33

45 Degree Bend* 150 1.72

90 Degree Bend* 150 3.44

* All bends on Flue/Exhaust Vent systems should be

long radius.

Inlet Duct/Pipe (For room sealed boilers only)

Item

Size

(mmØ)

Pressure Drop

(Pa)

1 m of Duct/Pipe 100 0.35

45 Degree Bend 100 0.19

90 Degree Bend 100 0.49

1 m of Duct/Pipe 80 1.00

45 Degree Bend 80 0.47

90 Degree Bend 80 1.18

2.14.2

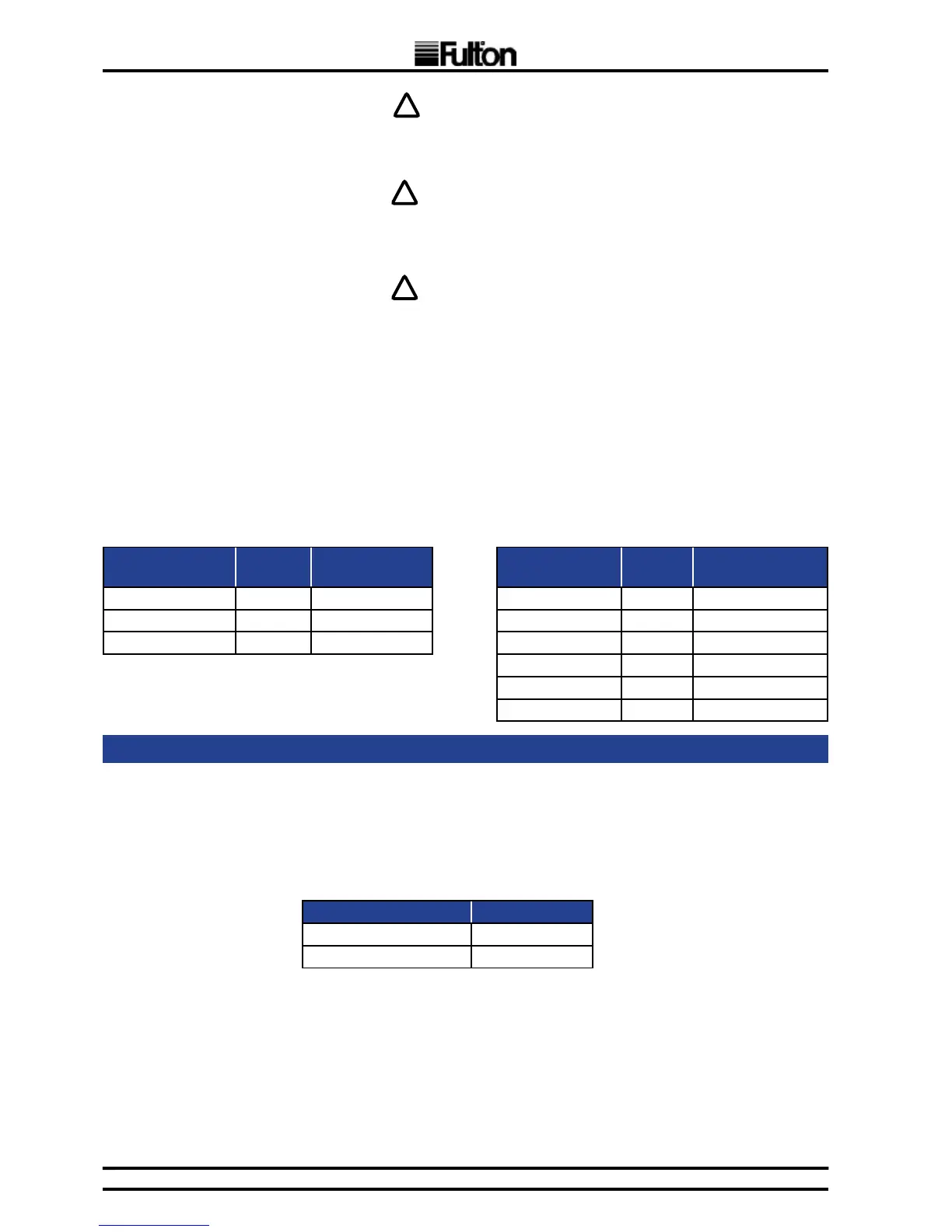

FLUE GAS CONDITIONS

Following installation of the ue(s) for the boiler, and set-up/commissioning of the burner, the following

should be used as a guide for the ue gas content and temperature.

For further details of the boiler set-up and commissioning, refer to section 3 of this manual.

Flue Gas Constituents

Item %

Carbon Dioxide (CO

2

) 9.5 ± 2.5

Carbon Monoxide (CO) 0.0075 ± 0.0075

Loading...

Loading...