Heat Demand

1. A thermostat (or a volt free contact) can be wired into screw terminals for CH and/or DHW as

applicable to the installation.

2. An external controller with OpenTherm communication port can be wired into the boilers. In this

case the controller will generate the required setpoint for CH only. This needs to be wired

parallel to all of the boilers. Please nd the supported OpenTherm system messages in the

table below.

Master

Boiler

Slave 1

Boiler

Slave 2

Boiler

Slave 3

Boiler

15

14

17

16

19

18

20

15

14

17

16

19

18

20

15

14

17

16

19

18

20

15

14

17

16

19

18

20

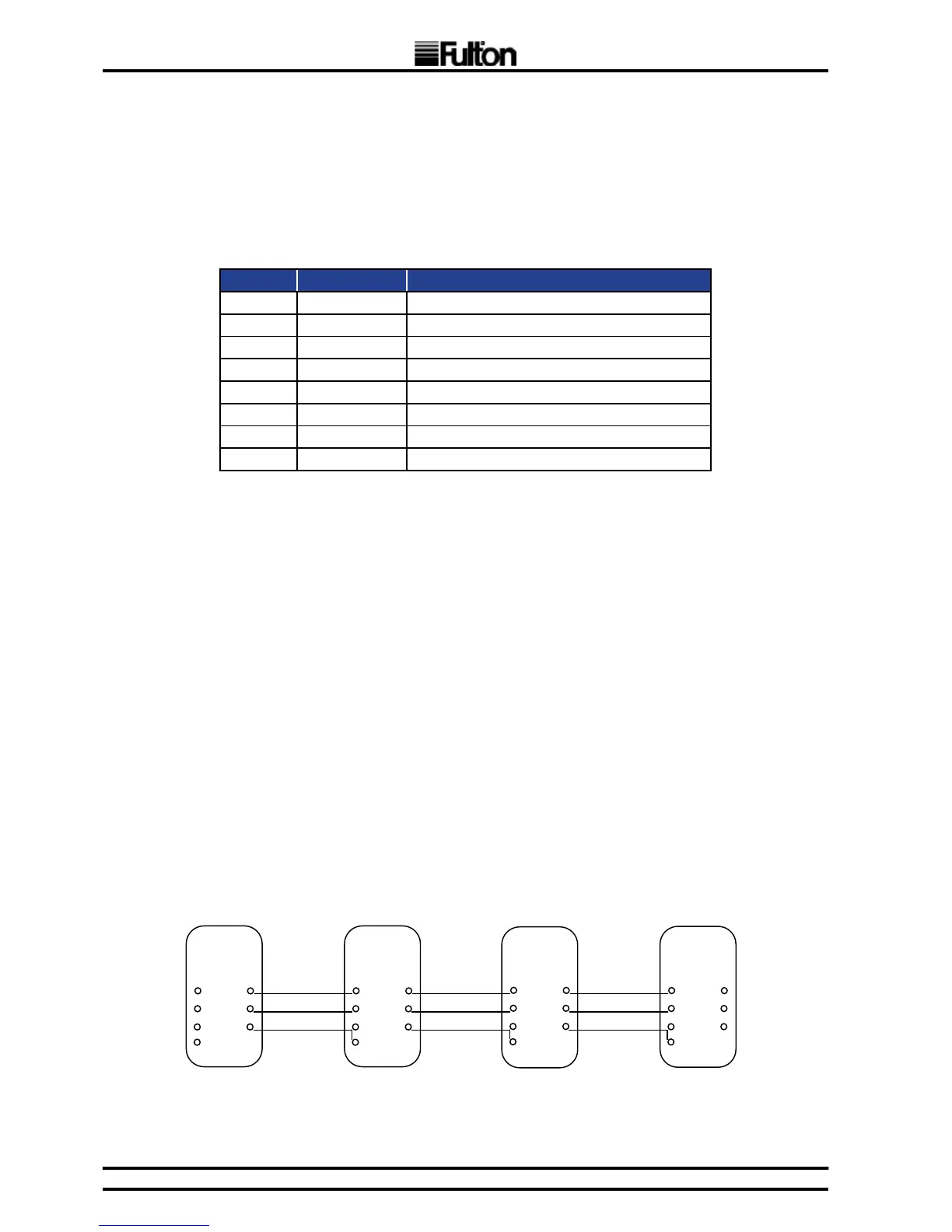

ID Read/Write Description

0 R Status

1 W Control Setpoint

5 R Fault ags/code

2 W Master Conguration (dummy write)

3 R Slave Conguration

4 W Lockout Reset

17 R Relative Modulation Level

25 R CH Water Temperature

For details of the terminal connections to use for the thermostat(s) and OpenTherm controller, refer

to the tables in Section 2.19.2 of this manual.

Cascade Temperature Sensor (Header Sensor)

A cascade temperature sensor is provided to monitor the desired set point temperature to

control the boiler outputs. This needs to be placed after the boiler header at an appropriate point in

the system ow pipework.

The sensor needs to be wired in parallel to all of the boilers.

Boiler Status Signals

A normally open volts free contact is provided to indicate a fault of the boiler to remote system

controls. Please refer to the tables in Section 2.19.2 - Terminal Connections for External Wiring.

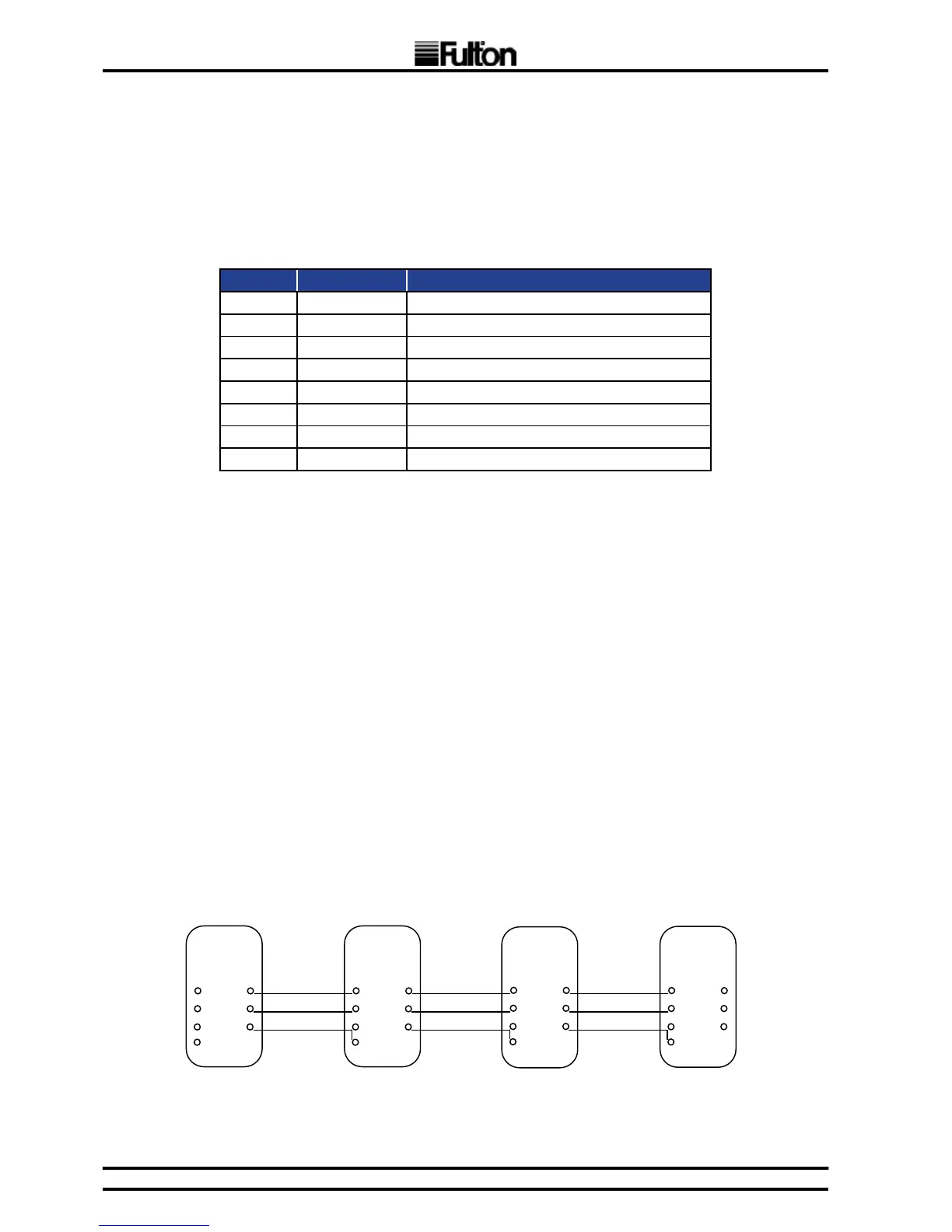

Boiler Communication Cables

The gure below shows the wire connections between the boilers in a cascade system.

* Link Terminal 19 and 20

FIG. 6 BOILER COMMUNICATION CABLES

Loading...

Loading...