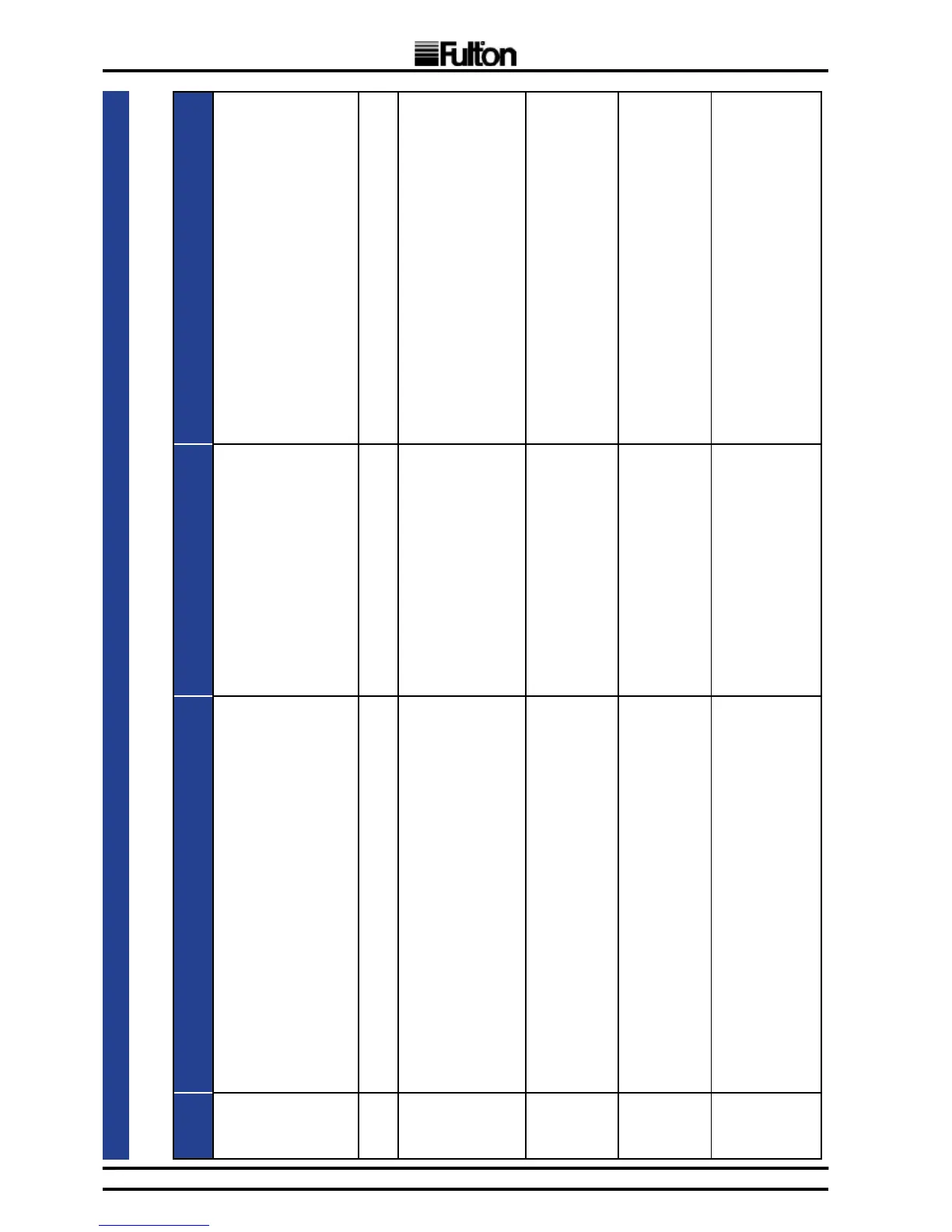

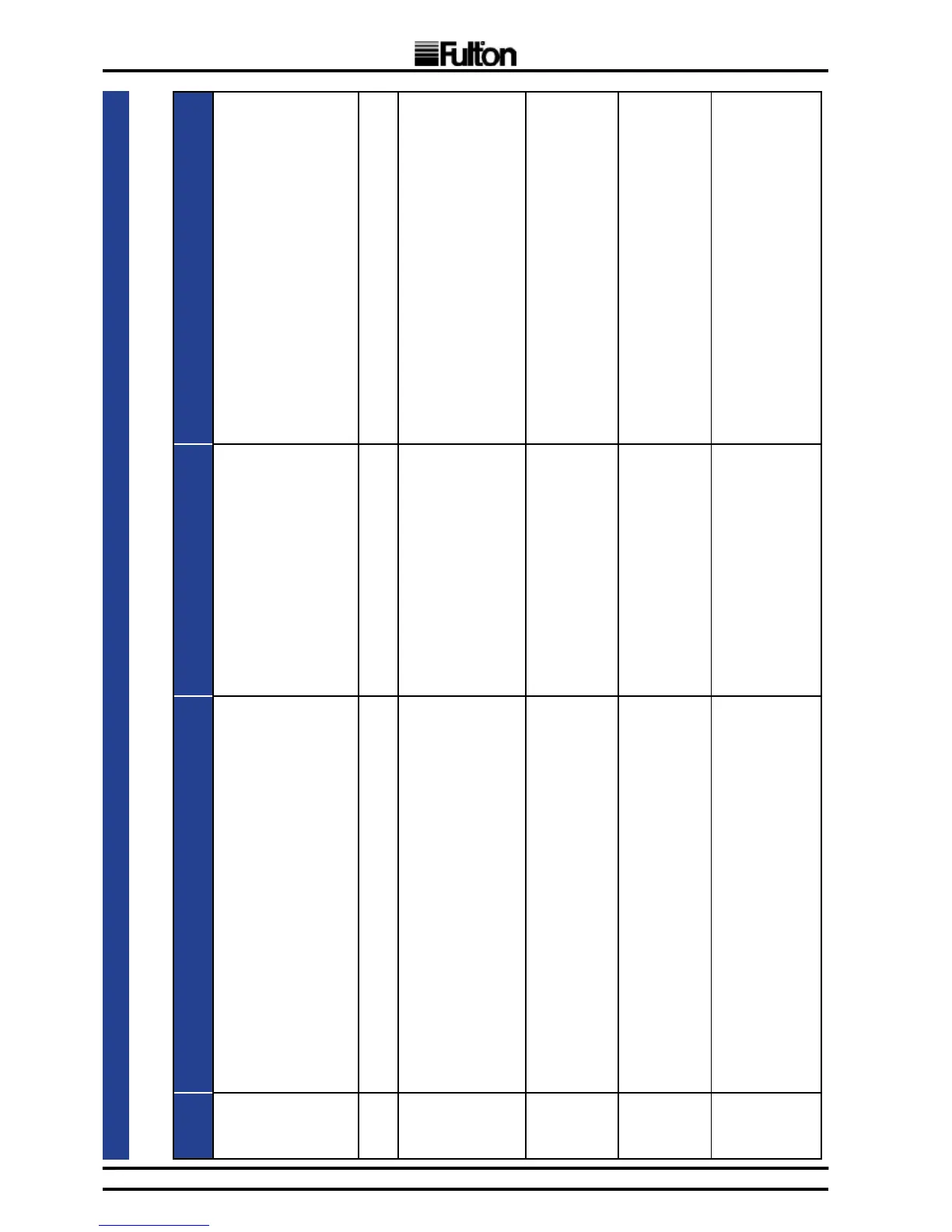

1. LOCK OUT ERROR CODES

Lock out error codes require a manual reset action after the source of the problem has been identied and eliminated. The meaning of the error numbers

are as follows:

ERROR

CODE

MEANING POSSIBLE CAUSE SOLUTION

A1

Lock out signal after no ame and all ignition trials are

expired

Description:

This error condition stops the boiler from operating and

manual/remote reset is required. Local resets are not

limited. However remote resets (communication or

Open Therm) are limited to 5 per hour.

a) Manually operated valves on the

gas train have been closed.

b) There is a blockage in the gas

line.

c) Modulating gas valve within the

boiler is not operating correctly.

d) Modulating gas valve within the

boiler has failed.

a) Check and open the manually operated valves

including the T-handle valve in the boiler shell.

b) Check the operation of any other equipment,

connected upstream of the boiler, on the gas line.

c) Check the tube between the gas valve and the

Venturi and ensure that both ends are properly

connected.

d) Replace the modulating gas valve.

A2 False Flame Signal

A ame signal is seen without the

gas valve being open.

Clean isolation probe. Reset lockout.

A3

Overheat Protection

Description:

This error code can be generated by one of two methods of

overheat protection built into the boilers. A High Limit error

can be generated even after a CH supply or return sensor

short circuit condition occurs.

There is a signal coming from the

CH ow or return temperature

sensors in excess of 105°C, or the

heat exchanger body is higher than

95°C, so the circuit is open through

the high limit stat (this is normally

closed).

a) Clean CH ow and return temperature sensors.

b) Check wiring between the controller and the limit

stat and make sure that the wires connected are

not loose. If all the wiring is ne then replace the

high limit stat.

c) If the problem still persists, then replace ow and

return temperature sensors

A4

APS (Air Pressure Switch) Error

Description:

The APS is congured and does not close or does not open

within set time limits. Error 4 is generated.

APS ap valve has stuck open, or

closed.

Remove the apper house between the fan and the

heat exchanger and clean the housing inside. If this

does not solve the problem, then replace the APS

apper.

A5

Fan Speed Feedback Error

Description:

The control requires a certain fan speed, but does not

detect the correct signal.

The fan motor is not working

correctly.

Replace the fan unit on the burner.

A6

APS (Air Pressure Switch) Error

Description:

If the APS is congured and it drops during burner

operation and the number of maximum re-trials has been

reached, Error 6 is generated.

A foreign body blocking the air

supply.

Check that the airway to the burner is clear from

obstructions.

Loading...

Loading...