DMC-1000 Chapter 6 Programming Motion • 73

Note: Closed loop operation with a stepper motor is not possible.

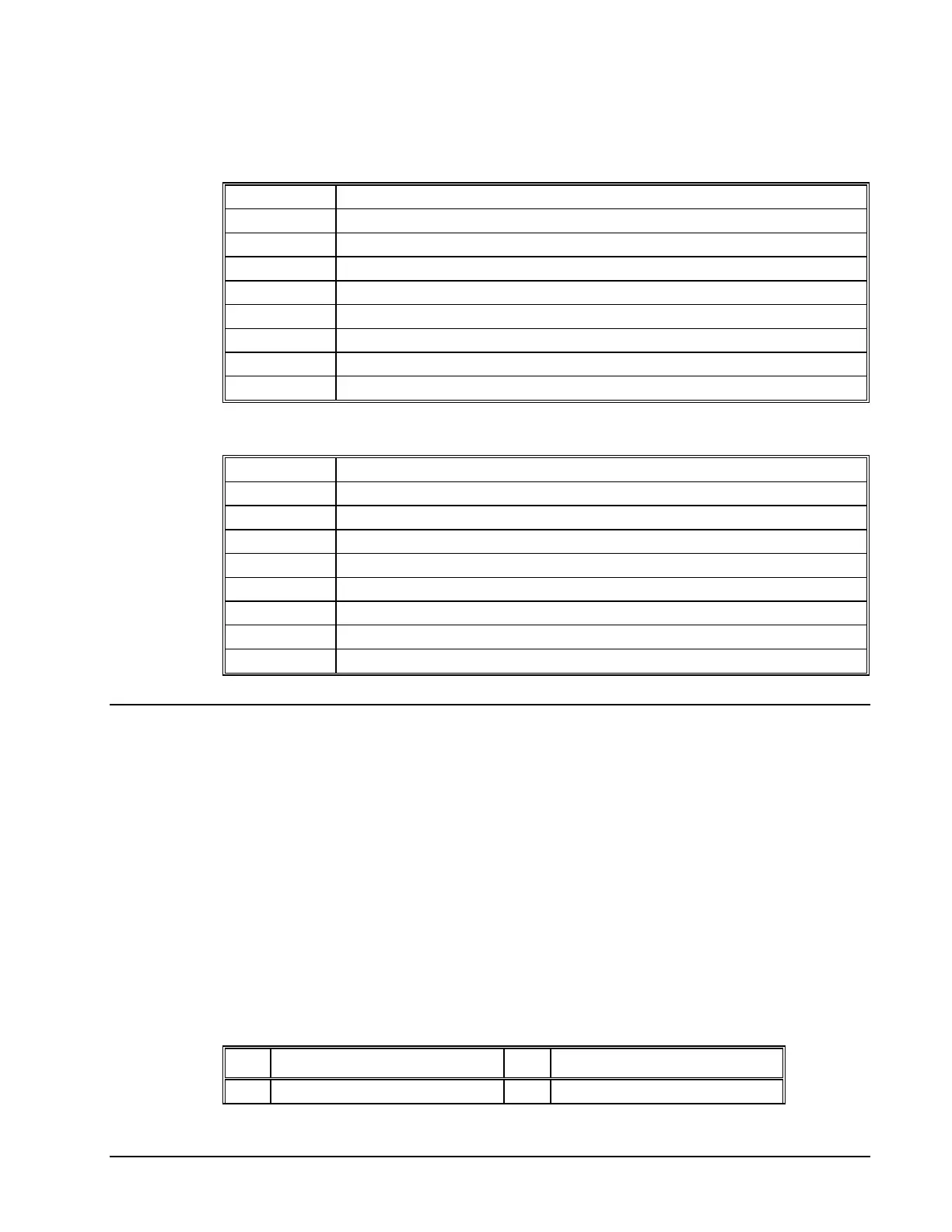

Command Summary - Stepper Motor Operation

COMMAND DESCRIPTION

DE Define Encoder Position (When using an encoder)

DP Define Reference Position and Step Count Register

IT Motion Profile Smoothing - Independent Time Constant

KS Stepper Motor Smoothing

MT Motor Type (2,-2,2.5 or -2.5 for stepper motors)

RP Report Commanded Position

TD Report number of step pulses generated by controller

TP Tell Position of Encoder

Operand Summary - Stepper Motor Operation

OPERAND DESCRIPTION

_DEx Contains the value of the step count register

_DPx Contains the value of the main encoder

_ITx Contains the value of the Independent Time constant for the 'x' axis

_KS Contains the value of the Stepper Motor Smoothing Constant for the 'x' axis

_MT Contains the motor type value for the 'x' axis

_RP Contains the commanded position generated by the profiler

_TD Contains the value of the step count register

_TP Contains the value of the main encoder

Dual Loop (Auxiliary Encoder)

The DMC-1000 provides an interface for a second encoder for each axis except for axes configured

for stepper motor operation. When used, the second encoder is typically mounted on the motor or the

load, but may be mounted in any position. The most common use for the second encoder is backlash

compensation, described below.

The auxiliary encoder may also be used for gearing. In this case, the auxiliary encoder input is used to

monitor an encoder which is not under control of the DMC-1000. To use the auxiliary encoder for

gearing, the master axis is specified as the auxiliary encoder and GR is used to specify the gear ratios.

For more information, see previous section

Electronic Gearing on page 58.

The second encoder may be a standard quadrature type, or it may provide pulse and direction. The

controller also offers the provision for inverting the direction of the encoder rotation. The main and

the auxiliary encoders are configured with the CE command. The command form is CE x,y,z,w (or

a,b,c,d,e,f,g,h for controllers with more than 4 axes) where the parameters x,y,z,w each equal the sum

of two integers m and n. m configures the main encoder and n configures the auxiliary encoder.

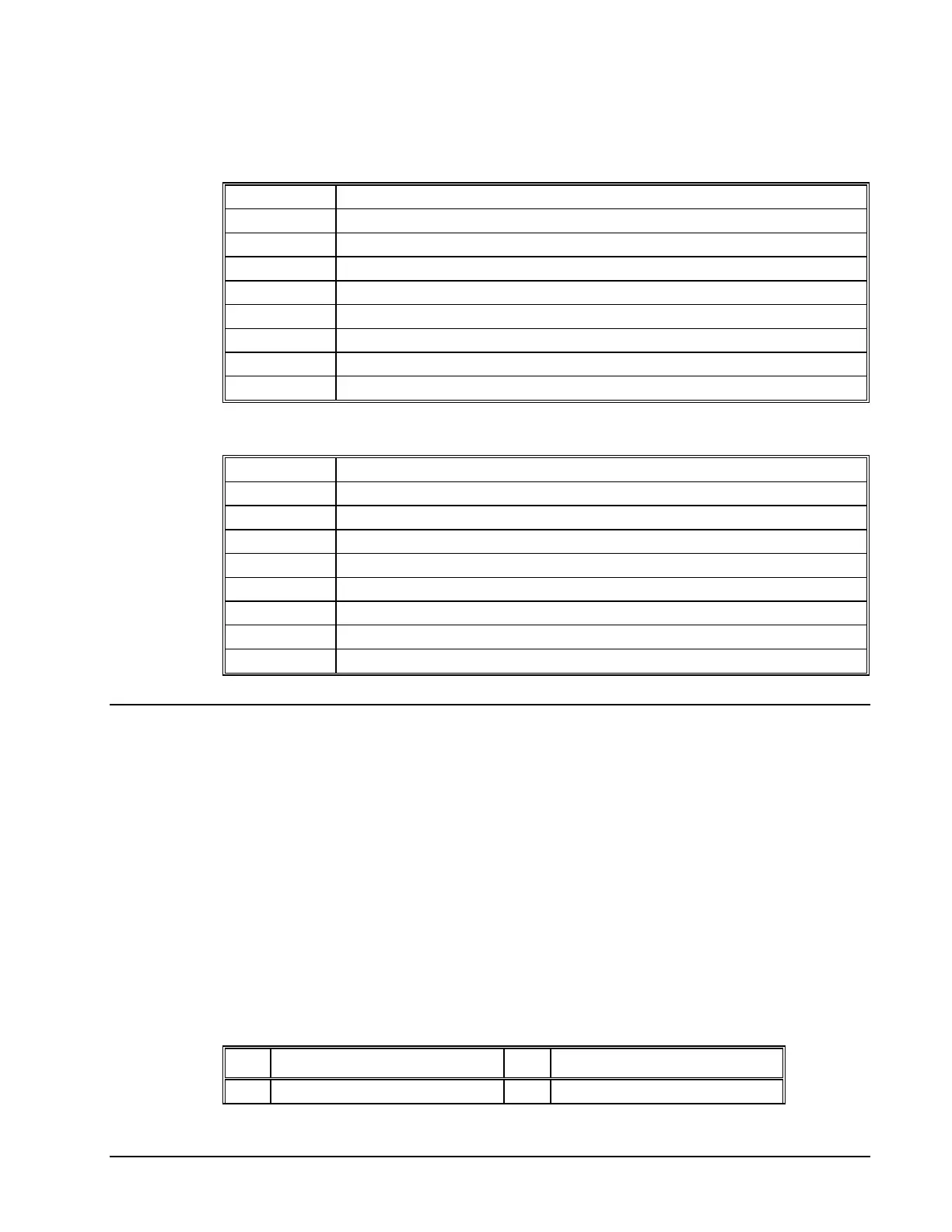

Using the CE Command

m= Main Encoder n= Second Encoder

0 Normal quadrature 0 Normal quadrature

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...