2 • Chapter 1 Overview DMC-1000

2. Step motors with step and direction signals

3. Other actuators such as hydraulics - For more information, contact Galil.

The user can configure each axis for any combination of motor types, providing maximum flexibility.

Standard Servo Motors with +/- 10 Volt Command

Signal

The DMC-1000 achieves superior precision through use of a 16-bit motor command output DAC and

a sophisticated PID filter that features velocity and acceleration feedforward, an extra pole filter and

integration limits.

The controller is configured by the factory for standard servo motor operation. In this configuration,

the controller provides an analog signal (+/- 10Volt) to connect to a servo amplifier. This connection

is described in Chapter 2.

Stepper Motor with Step and Direction Signals

The DMC-1000 can control stepper motors. In this mode, the controller provides two signals to

connect to the stepper motor: Step and Direction. For stepper motor operation, the controller does not

require an encoder and operates the stepper motor in an open loop fashion. Chapter 2 describes the

proper connection and procedure for using stepper motors.

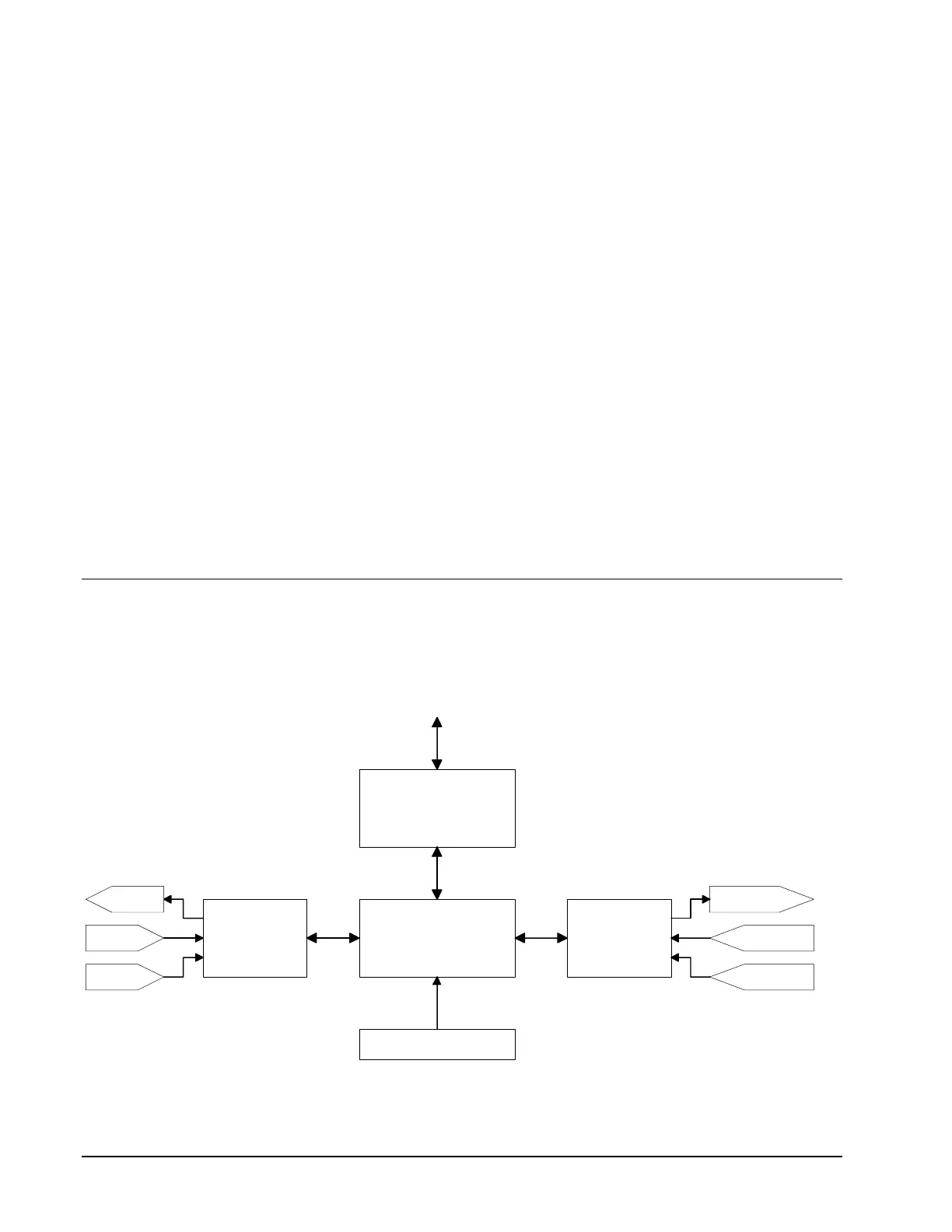

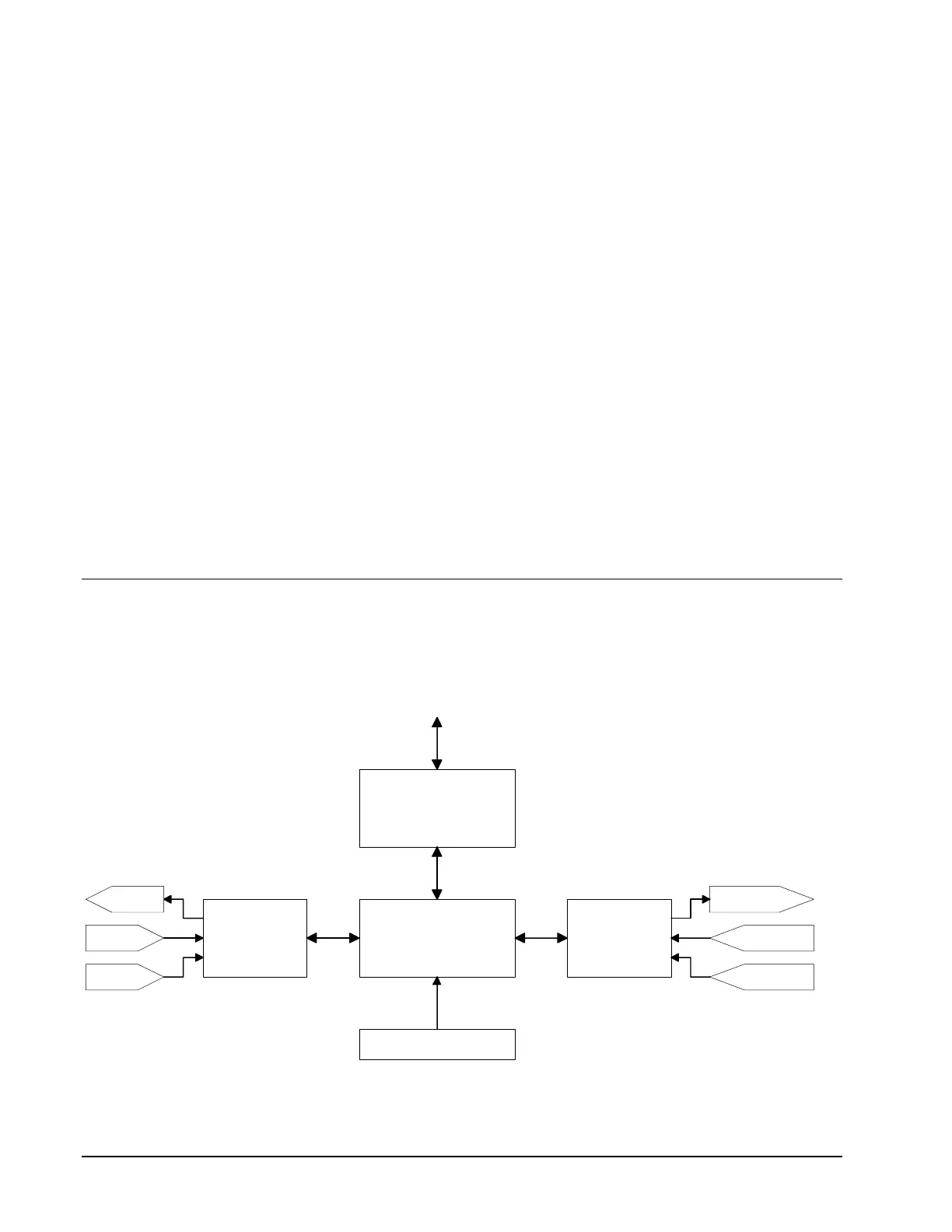

DMC-1000 Functional Elements

The DMC-1000 circuitry can be divided into the following functional groups as shown in Figure 1.1

and discussed in the following.

68331

Microcomputer

64K RAM

64K EPROM

256 EEPROM

I/O

Interface

GL-1800

4-Axes

Motor/Encoder

Interface

Communication

FIFO

512 Bytes

Watch Dog

Timer

8 Out

8 In

8 Analog In

To Host

To Amps

From

Limits

From

Encoders

Figure 1.1 - DMC-1000 Functional Elements

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...