SecoGear Medium-voltage Switchgear Application and Technical Guide DET-882

Circuit Breaker Selection

12 ©2017 General Electric All Rights Reserved

tie breakers. In normal operating mode, each bus is served

by its own source through normally closed main breakers,

with the bus tie breaker open. If an outage occurs on one

of the incoming supplies, the incoming breaker connected

to that supply is opened, and then the bus is re-energized

by closing the bus tie breaker to transfer the dead bus to

the live (alternate) source.

To protect against damage to motors connected to the

dead bus, the bus tie breaker is typically not allowed to

close until the residual voltage on the effected bus has

decayed to a safe level. After the lost source has been

reestablished, the scheme provides two methods (auto and

manual) to restore the system to normal configuration.

If the sources cannot be synchronized, the bus tie breaker

must be manually opened before the open incomer can be

manually closed. In this procedure, the incomer will be

allowed to close only if the incoming source (line VT)

voltage is above a “live” threshold and the load (bus VT)

voltage is below a “dead” threshold value.

If the sources are synchronized, it is possible to manually

close the open incomer with synch check supervision to

parallel all three breakers. The scheme will then

automatically open a breaker which had been previously

selected to trip if all breakers become closed, in this

instance the bus tie breaker. Note that if momentary

paralleling is utilized, the equipment and breakers must be

rated for the total available fault current from the

combined sources.

The detection of an undervoltage event and the resulting

transfer logic can be accomplished using either discrete

protective relays, auxiliary relays and timers, or with a PLC

and programming, or by using the various protective relay

and logic features contained in today’s multifunction

relays, such as GE Multilin SR850. In addition to a protective

relay required for each of the three circuit breakers (both

mains and the tie), it is required to connect one contact

from a three-position switch to each breaker. This switch

(device 43/10) is used to select the breaker that will trip

after all breakers are closed. It is generally recommended

that a two-position switch (device 43/83) with three

contacts, be connected to each relay as an “Auto-Off”

transfer scheme selector.

Because a relay is required for each the three circuit

breakers, it allows bus-splitting. This operation is

accomplished by setting the time overcurrent elements in

the relay on the bus tie breaker to trip faster than the

incomers, opening the bus tie before an incomer when

operating from only one source.

Capacitor Switching

Capacitor banks are generally applied on both utility and

industrial power systems to improve voltage regulation

and system stability. SecoVac VB2+ circuit breakers

properly equipped are applicable as circuit breakers for

small shunt-capacitor-bank switching applications.

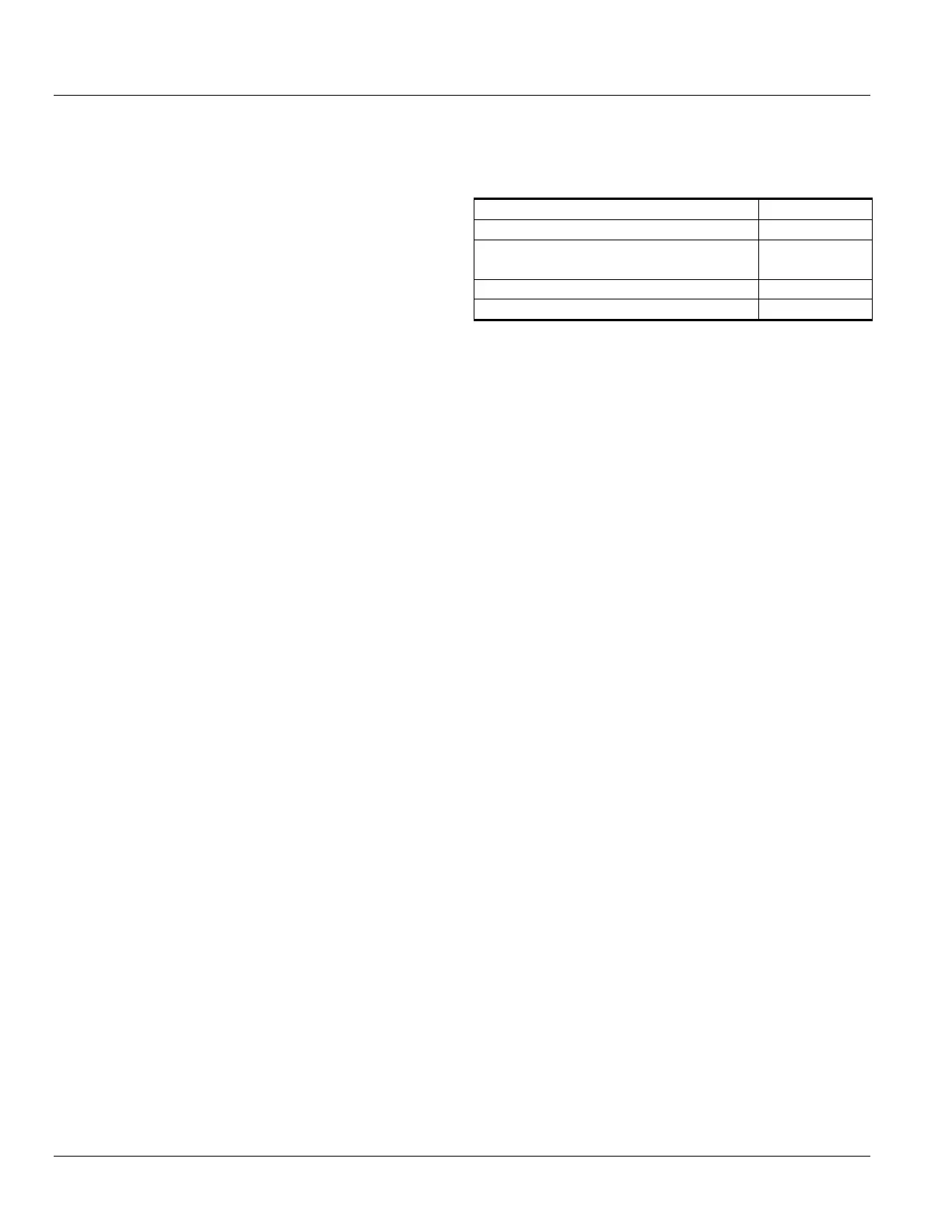

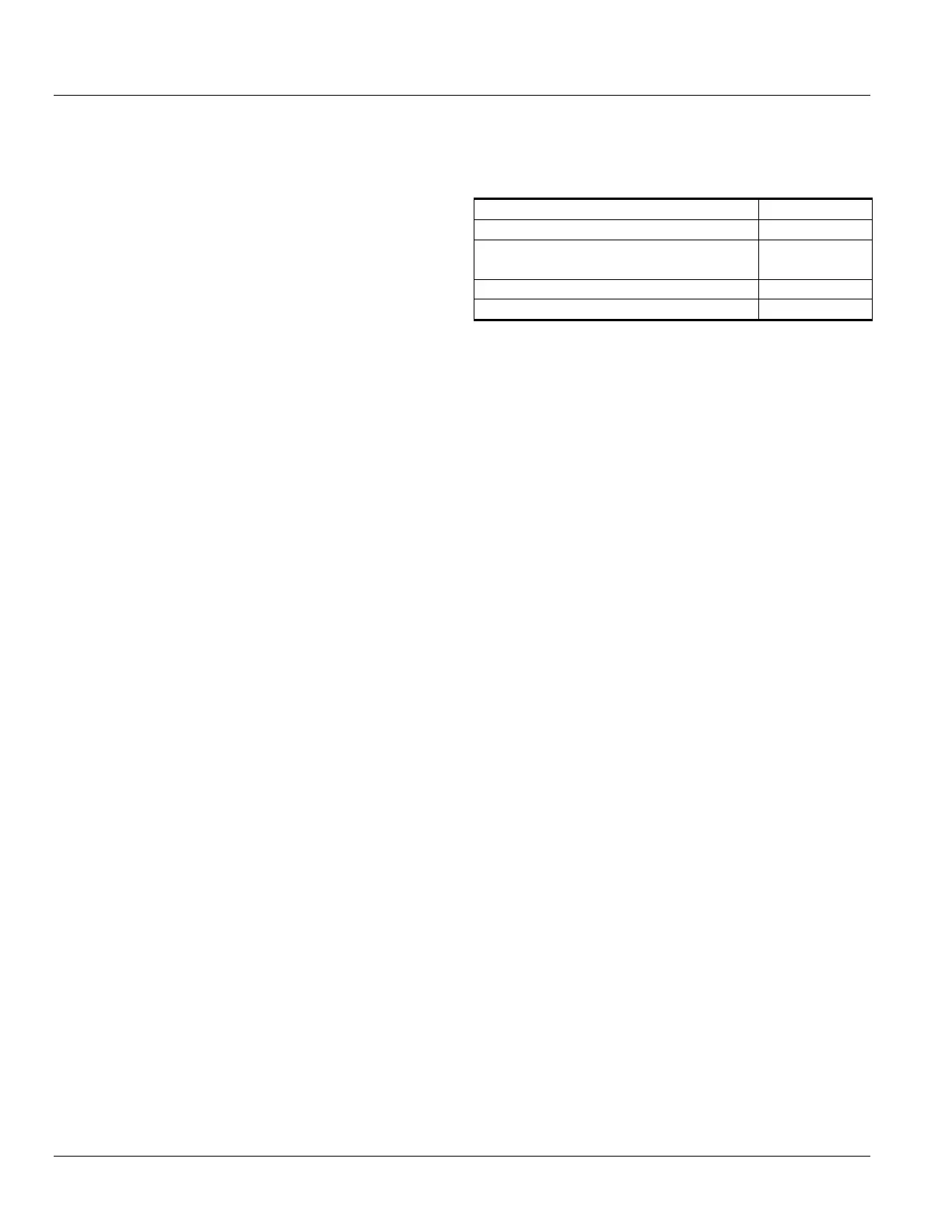

Table 2-2: SecoVac Breaker

Capacitor Switching Capabilities

Rated Short-circuit Current

Single Bank Rated Capacitor Breaking

Current (1200 A Breaker)

250 A

C2

60 Hz

SERVICE CONDITIONS

ANSI defines specific service conditions as “usual” or

“unusual” for the operation of metal-clad switchgear;

based on factors such as altitude, temperature, humidity

and a variety of others, like presence of atmospheric

contaminants storage conditions and tamper resistance.

ANSI C37.04 specifies service conditions for circuit breakers

and ANSI C37.20.2 for metal-clad switchgear.

Usual Service Conditions

SecoVac VB2+ circuit breakers and the complete SecoGear

switchgear assembly are designed for usual service

conditions at their standard nameplate ratings;

• Ambient temperature range: maximum 40 °C [104 °F]

and minimum -30°C [-22 °F]

• Altitude: maximum 1000 m [3300 feet]

Unusual Service Conditions

Abnormal Temperature

For special applications with unusual service conditions

such as ambient temperature outside normal range (-30 °C

[-22 °F] to 40 °C [104 °F], consult ANSI C37.20.2 for derating

values applicable. Refer special or abnormal applications to

GE for evaluation.

Temperature Rise

The temperature of the buses and bolted connections in

any switchgear assembly must not exceed 65 °C [149 °F]

when operating under full load current, and the total hot

spot must not exceed 105 °C [221 °F], as stated in ANSI

C37.20.2. Connections to insulated cables must not exceed

a 45 °C [113 °F] temperature rise, and an 85 °C [185 °F] hot

spot temperature when operated at rated continuous

current in rms amperes at rated frequency.

High Altitude

There are two characteristics to take into consideration

when designing medium voltage metal-clad switchgear at

altitudes above 1000 meters [3300 ft]: continuous current

rating and dielectric withstand capability. Both of them use

Loading...

Loading...