PRINTED IN U.S.A. 43 913287/BP0808

SUSPENDED LOADS

DO NOT exceed the Telescopic Handler capacity as

equipped for handling suspended loads. Only lift the

load vertically and NEVER drag it horizontally. Use

tag lines to restrain load swing whenever possible.

The handling of suspended loads by means of the truss

boom or other similar device can introduce dynamic

forces affecting the stability of the machine that are not

considered in the stability criteria of industry test stan-

dards. Grades and sudden starts, stops and turns can

cause the load to swing and create a hazard.

Guidelines for “Free Rigging / Suspended

Loads”

1. The rigging equipment must be in good condition

and comply with U.S. OSHA regulation

1910.184, “Slings,” or 1926.251, “Rigging equip-

ment for material handling.”

2. The rigging equipment must be secured to the

forks such that it cannot slip or slide either side-

ways or fore and aft.

3. The capacity of the fork(s) and the machine

(whichever is less) must not be exceeded.

4. The load center must remain at 24” (610 mm) or

less.

5. No lifting of material may be done when anyone

is on the load, rigging or forks.

6. Multiple pickup points on the load are preferred

to prevent the load from rotating, but a single

pickup point may be used if one or more tag lines

are utilized. And, of course, the load must never

be postioned over personnel at any time.

MATERIAL HANDLING BUCKET TOOL

APPLICATION

IMPORTANT: The 55’ model is not intended for

ground or material pile engagement. The bucket

should be used for light-duty site cleanup only.

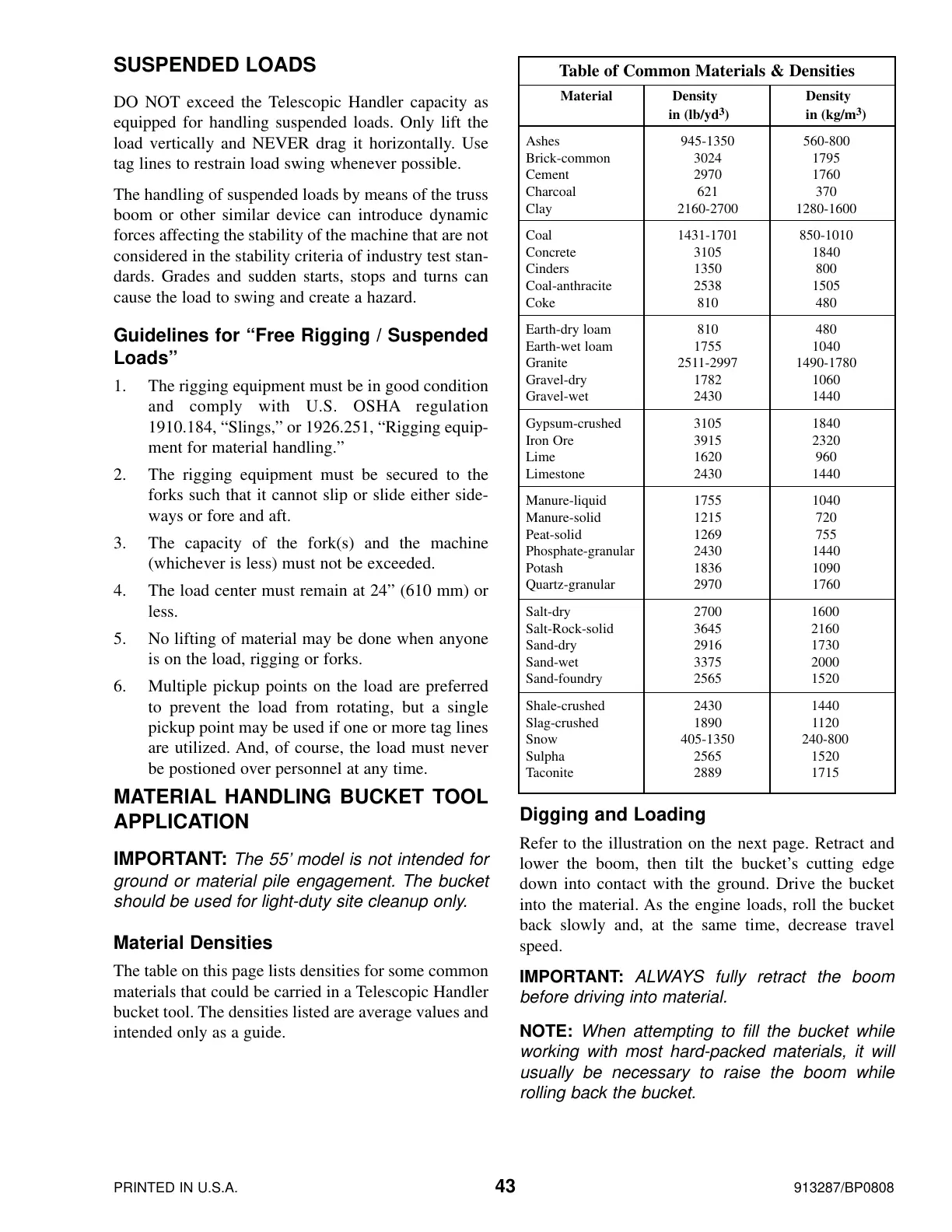

Material Densities

The table on this page lists densities for some common

materials that could be carried in a Telescopic Handler

bucket tool. The densities listed are average values and

intended only as a guide.

Table of Common Materials & Densities

Material Density Density

in (lb/yd

3

) in (kg/m

3

)

Ashes 945-1350 560-800

Brick-common 3024 1795

Cement 2970 1760

Charcoal 621 370

Clay 2160-2700 1280-1600

Coal 1431-1701 850-1010

Concrete 3105 1840

Cinders 1350 800

Coal-anthracite 2538 1505

Coke 810 480

Earth-dry loam 810 480

Earth-wet loam 1755 1040

Granite 2511-2997 1490-1780

Gravel-dry 1782 1060

Gravel-wet 2430 1440

Gypsum-crushed 3105 1840

Iron Ore 3915 2320

Lime 1620 960

Limestone 2430 1440

Manure-liquid 1755 1040

Manure-solid 1215 720

Peat-solid 1269 755

Phosphate-granular 2430 1440

Potash 1836 1090

Quartz-granular 2970 1760

Salt-dry 2700 1600

Salt-Rock-solid 3645 2160

Sand-dry 2916 1730

Sand-wet 3375 2000

Sand-foundry 2565 1520

Shale-crushed 2430 1440

Slag-crushed 1890 1120

Snow 405-1350 240-800

Sulpha 2565 1520

Taconite 2889 1715

Digging and Loading

Refer to the illustration on the next page. Retract and

lower the boom, then tilt the bucket’s cutting edge

down into contact with the ground. Drive the bucket

into the material. As the engine loads, roll the bucket

back slowly and, at the same time, decrease travel

speed.

IMPORTANT: ALWAYS fully retract the boom

before driving into material.

NOTE: When attempting to fill the bucket while

working with most hard-packed materials, it will

usually be necessary to raise the boom while

rolling back the bucket.

Courtesy of Crane.Market

Loading...

Loading...