PRINTED IN U.S.A. 57 913287/BP0808

1. Thoroughly clean fuel filter assemblies and sur-

rounding areas.

2. Disconnect water sensor wiring.

3. Loosen drain plugs (C) and drain fuel into a suit-

able container.

4. Firmly grasp the retaining ring (A) and rotate it

clockwise 1/4 turn (when viewed from the top).

Remove the ring with filter element (B or F).

NOTE: Lifting up on retaining ring (A) as it is rotat-

ed helps to get it past raised locators.

5. Inspect filter mounting base for cleanliness. Clean

as required.

NOTE: Raised locators on the fuel filter canister

must be indexed properly with slots in mounting

base for correct installation.

6. Install new filter elements onto mounting bases.

Be sure elements are properly indexed and firmly

seated on bases. It may be necessary to rotate fil-

ters for correct alignment.

If equipped with water seperator bowl (E),

remove filter element from seperator bowl. Drain

and clean the separator bowl. Dry with com-

pressed air. Install bowl onto new element.

Tighten securely.

7. Align keyes on filter element with slots in filter

base.

8. Install retaining ring onto mounting base making

certain dust seal is in place on filter base. Hand

tighten ring counter-clockwise (about 1/3 turn)

until it snap into the detent. DO NOT overtighten

retaining ring.

NOTE: The proper installation is indicated when a

“click” is heard and a release of the retaining ring

is felt.

9. Reconnect water sensor wiring.

After fuel filter replacement, bleed the air out of the

fuel system by following the fuel bleeding procedure.

Fuel Bleeding Procedure

When the fuel filter is removed and replaced, or if the

engine runs out of fuel, air must be bled from the sys-

tem. Refer to the following procedure for proper bleed-

ing procedure.

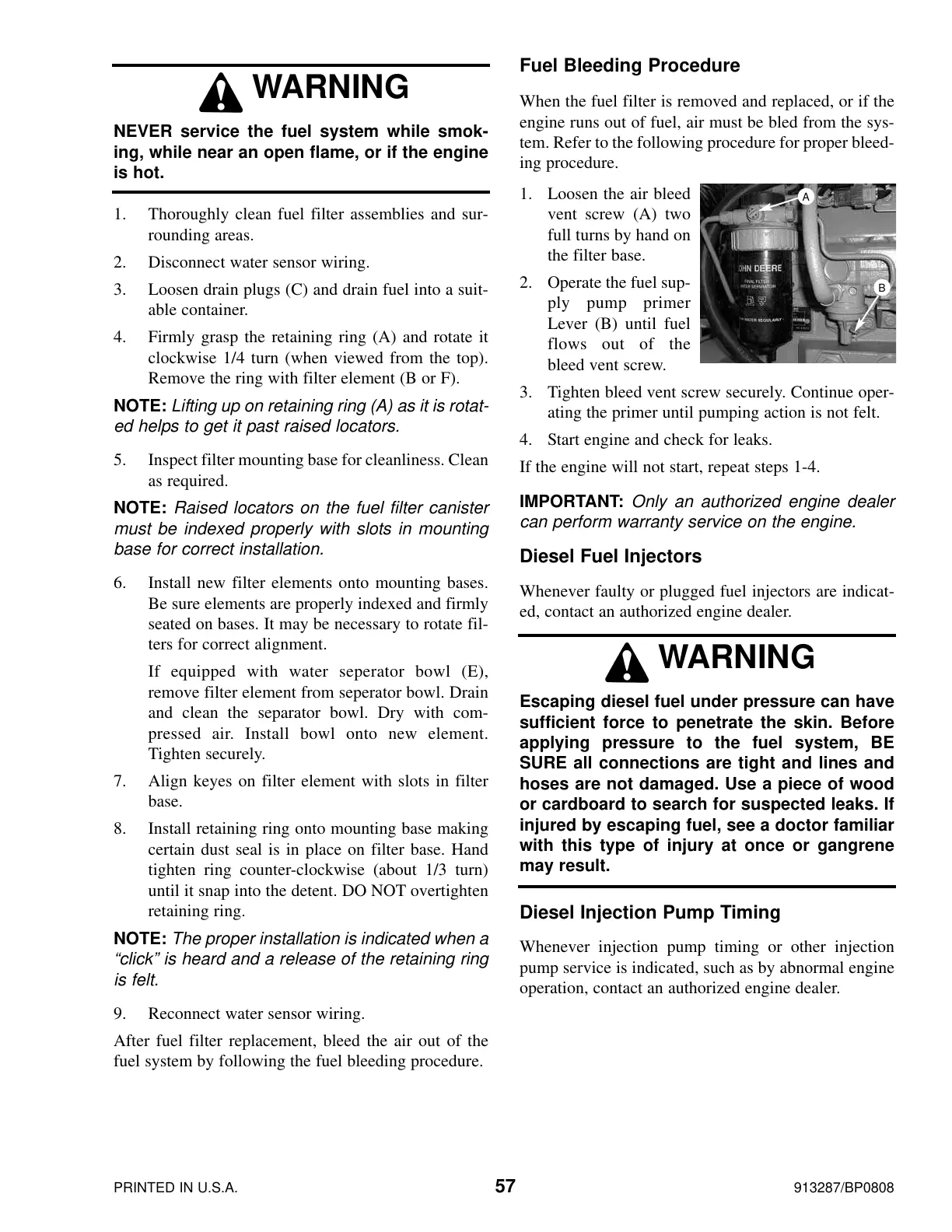

1. Loosen the air bleed

vent screw (A) two

full turns by hand on

the filter base.

2. Operate the fuel sup-

ply pump primer

Lever (B) until fuel

flows out of the

bleed vent screw.

3. Tighten bleed vent screw securely. Continue oper-

ating the primer until pumping action is not felt.

4. Start engine and check for leaks.

If the engine will not start, repeat steps 1-4.

IMPORTANT: Only an authorized engine dealer

can perform warranty service on the engine.

Diesel Fuel Injectors

Whenever faulty or plugged fuel injectors are indicat-

ed, contact an authorized engine dealer.

Diesel Injection Pump Timing

Whenever injection pump timing or other injection

pump service is indicated, such as by abnormal engine

operation, contact an authorized engine dealer.

WARNING

Escaping diesel fuel under pressure can have

sufficient force to penetrate the skin. Before

applying pressure to the fuel system, BE

SURE all connections are tight and lines and

hoses are not damaged. Use a piece of wood

or cardboard to search for suspected leaks. If

injured by escaping fuel, see a doctor familiar

with this type of injury at once or gangrene

may result.

WARNING

NEVER service the fuel system while smok-

ing, while near an open flame, or if the engine

is hot.

B

A

Courtesy of Crane.Market

Loading...

Loading...