PRINTED IN U.S.A. 83 913287/BP0808

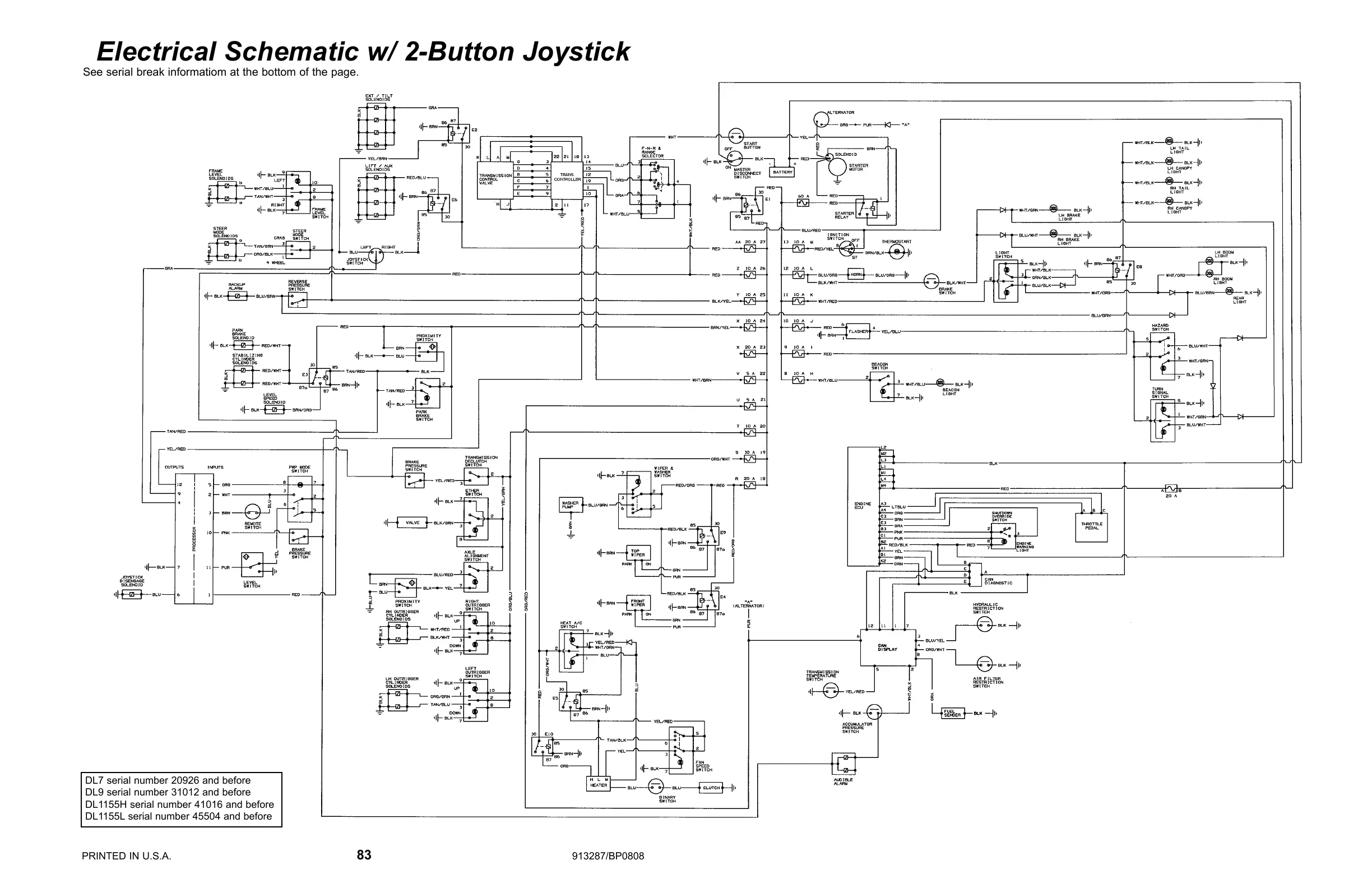

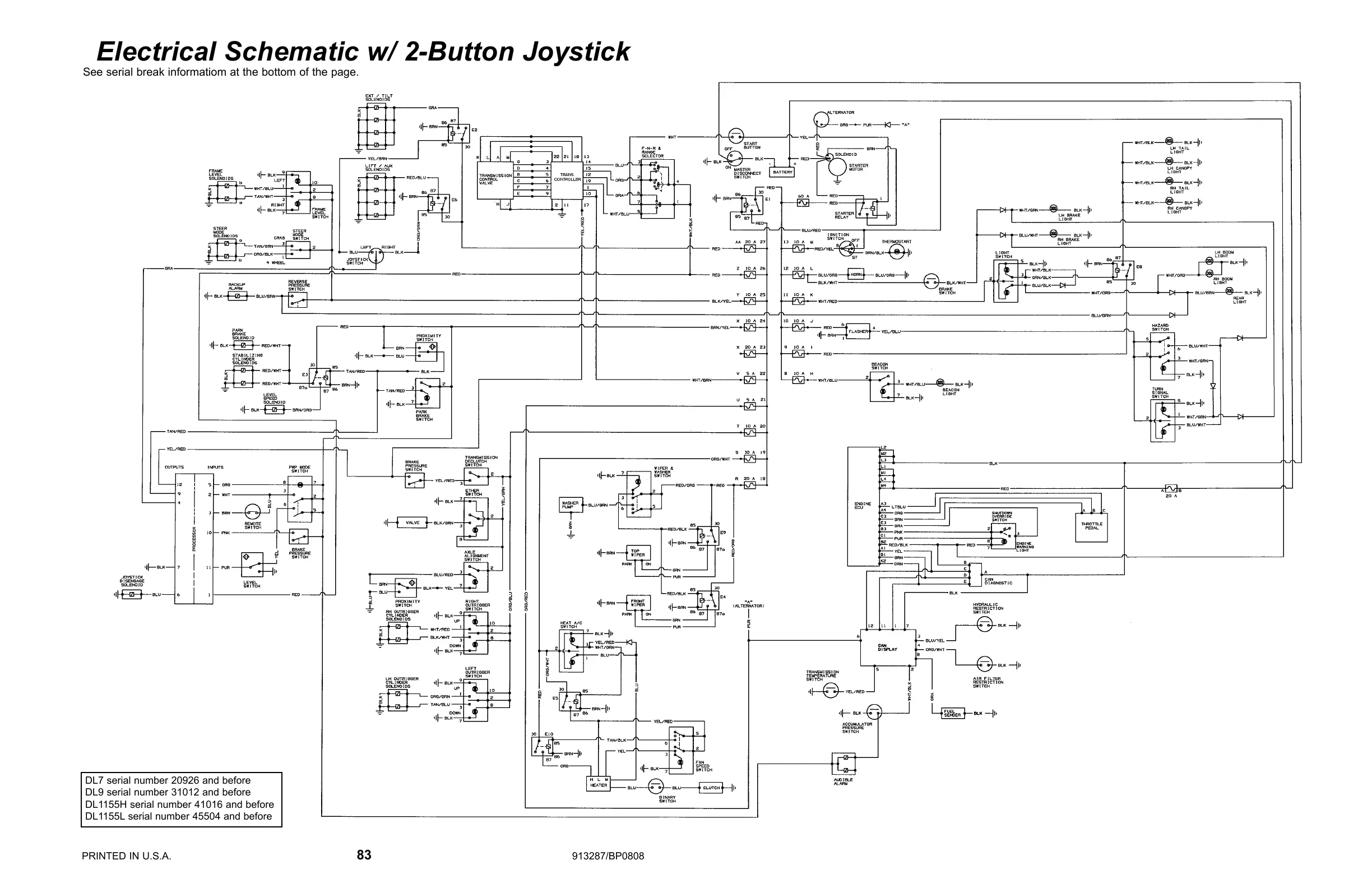

Electrical Schematic w/ 2-Button Joystick

DL7 serial number 20926 and before

DL9 serial number 31012 and before

DL1155H serial number 41016 and before

DL1155L serial number 45504 and before

See serial break informatiom at the bottom of the page.

Courtesy of Crane.Market

Loading...

Loading...