PRINTED IN U.S.A. 53 913287/BP0808

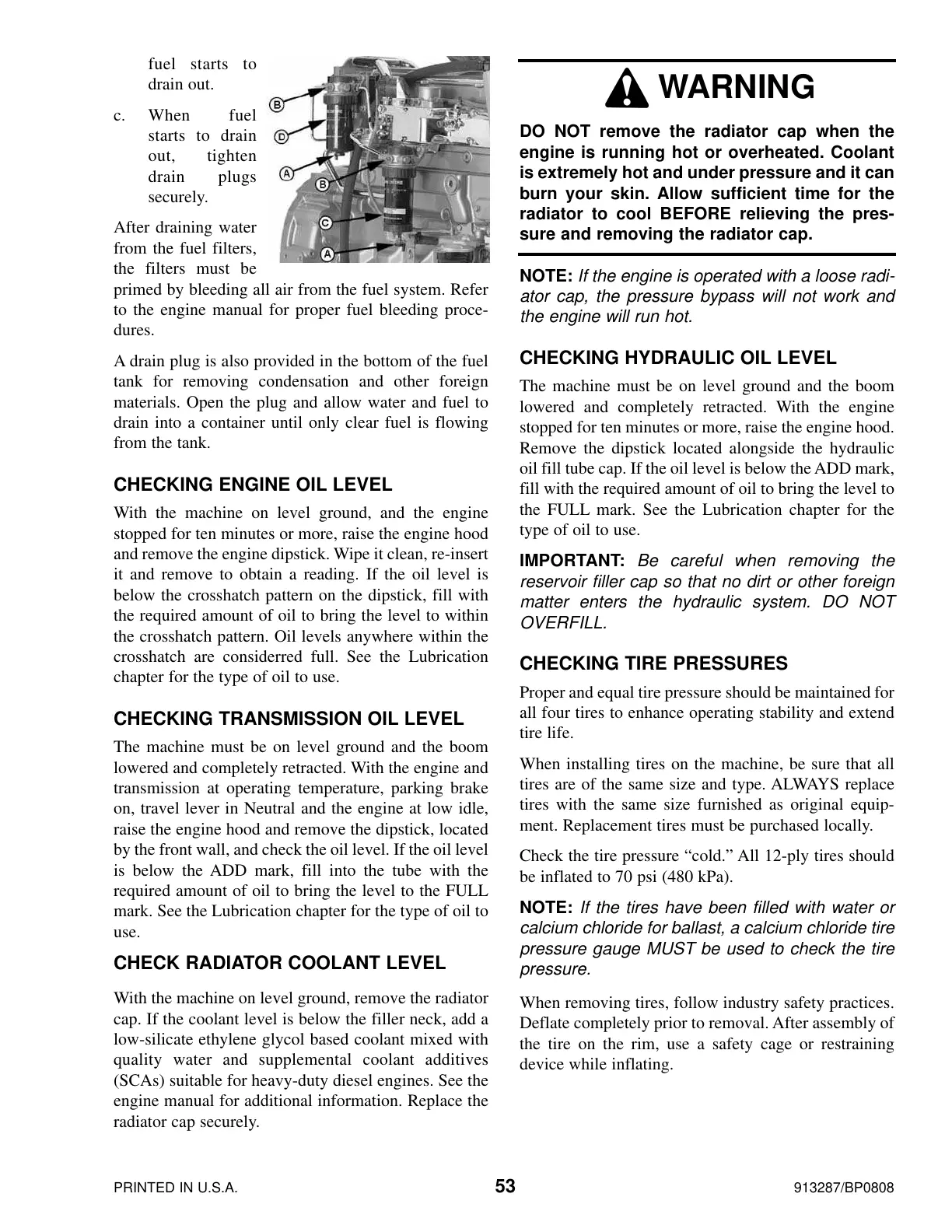

fuel starts to

drain out.

c. When fuel

starts to drain

out, tighten

drain plugs

securely.

After draining water

from the fuel filters,

the filters must be

primed by bleeding all air from the fuel system. Refer

to the engine manual for proper fuel bleeding proce-

dures.

A drain plug is also provided in the bottom of the fuel

tank for removing condensation and other foreign

materials. Open the plug and allow water and fuel to

drain into a container until only clear fuel is flowing

from the tank.

CHECKING ENGINE OIL LEVEL

With the machine on level ground, and the engine

stopped for ten minutes or more, raise the engine hood

and remove the engine dipstick. Wipe it clean, re-insert

it and remove to obtain a reading. If the oil level is

below the crosshatch pattern on the dipstick, fill with

the required amount of oil to bring the level to within

the crosshatch pattern. Oil levels anywhere within the

crosshatch are considerred full. See the Lubrication

chapter for the type of oil to use.

CHECKING TRANSMISSION OIL LEVEL

The machine must be on level ground and the boom

lowered and completely retracted. With the engine and

transmission at operating temperature, parking brake

on, travel lever in Neutral and the engine at low idle,

raise the engine hood and remove the dipstick, located

by the front wall, and check the oil level. If the oil level

is below the ADD mark, fill into the tube with the

required amount of oil to bring the level to the FULL

mark. See the Lubrication chapter for the type of oil to

use.

CHECK RADIATOR COOLANT LEVEL

With the machine on level ground, remove the radiator

cap. If the coolant level is below the filler neck, add a

low-silicate ethylene glycol based coolant mixed with

quality water and supplemental coolant additives

(SCAs) suitable for heavy-duty diesel engines. See the

engine manual for additional information. Replace the

radiator cap securely.

NOTE: If the engine is operated with a loose radi-

ator cap, the pressure bypass will not work and

the engine will run hot.

CHECKING HYDRAULIC OIL LEVEL

The machine must be on level ground and the boom

lowered and completely retracted. With the engine

stopped for ten minutes or more, raise the engine hood.

Remove the dipstick located alongside the hydraulic

oil fill tube cap. If the oil level is below the ADD mark,

fill with the required amount of oil to bring the level to

the FULL mark. See the Lubrication chapter for the

type of oil to use.

IMPORTANT: Be careful when removing the

reservoir filler cap so that no dirt or other foreign

matter enters the hydraulic system. DO NOT

OVERFILL.

CHECKING TIRE PRESSURES

Proper and equal tire pressure should be maintained for

all four tires to enhance operating stability and extend

tire life.

When installing tires on the machine, be sure that all

tires are of the same size and type. ALWAYS replace

tires with the same size furnished as original equip-

ment. Replacement tires must be purchased locally.

Check the tire pressure “cold.” All 12-ply tires should

be inflated to 70 psi (480 kPa).

NOTE: If the tires have been filled with water or

calcium chloride for ballast, a calcium chloride tire

pressure gauge MUST be used to check the tire

pressure.

When removing tires, follow industry safety practices.

Deflate completely prior to removal. After assembly of

the tire on the rim, use a safety cage or restraining

device while inflating.

WARNING

DO NOT remove the radiator cap when the

engine is running hot or overheated. Coolant

is extremely hot and under pressure and it can

burn your skin. Allow sufficient time for the

radiator to cool BEFORE relieving the pres-

sure and removing the radiator cap.

Courtesy of Crane.Market

Loading...

Loading...