PRINTED IN U.S.A. 61 913287/BP0808

1. Remove the drain plug and drain oil. Replace the

drain plug.

IMPORTANT: DO NOT discharge oil onto ground.

Catch and dispose of per local waste disposal

regulations.

2. Remove and discard the oil filter. Wipe the seal-

ing surface on the transmission with a clean cloth.

Apply a thin coat of clean oil to the new oil filter

gasket. Spin tighten.

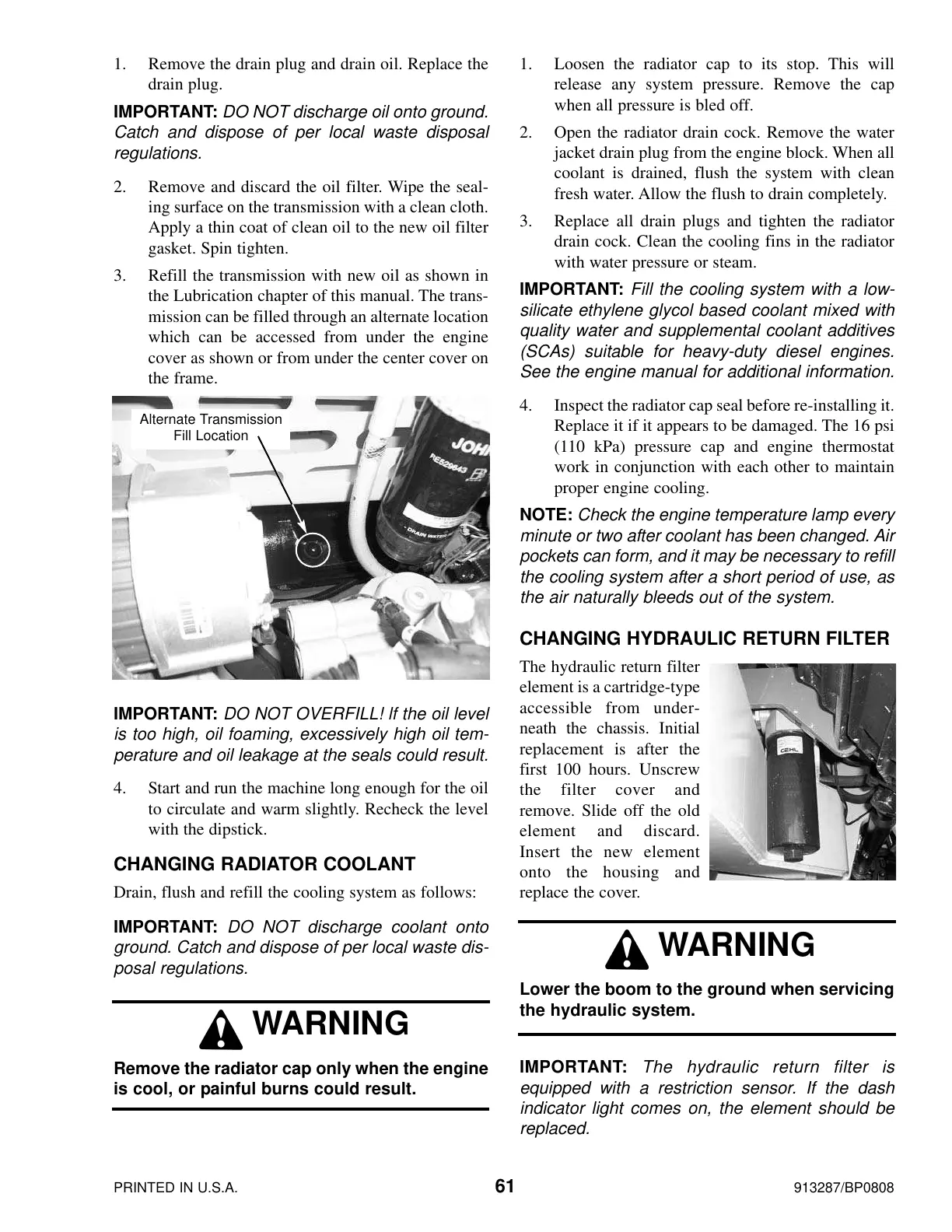

3. Refill the transmission with new oil as shown in

the Lubrication chapter of this manual. The trans-

mission can be filled through an alternate location

which can be accessed from under the engine

cover as shown or from under the center cover on

the frame.

IMPORTANT: DO NOT OVERFILL! lf the oil level

is too high, oil foaming, excessively high oil tem-

perature and oil leakage at the seals could result.

4. Start and run the machine long enough for the oil

to circulate and warm slightly. Recheck the level

with the dipstick.

CHANGING RADIATOR COOLANT

Drain, flush and refill the cooling system as follows:

IMPORTANT: DO NOT discharge coolant onto

ground. Catch and dispose of per local waste dis-

posal regulations.

1. Loosen the radiator cap to its stop. This will

release any system pressure. Remove the cap

when all pressure is bled off.

2. Open the radiator drain cock. Remove the water

jacket drain plug from the engine block. When all

coolant is drained, flush the system with clean

fresh water. Allow the flush to drain completely.

3. Replace all drain plugs and tighten the radiator

drain cock. Clean the cooling fins in the radiator

with water pressure or steam.

IMPORTANT: Fill the cooling system with a low-

silicate ethylene glycol based coolant mixed with

quality water and supplemental coolant additives

(SCAs) suitable for heavy-duty diesel engines.

See the engine manual for additional information.

4. Inspect the radiator cap seal before re-installing it.

Replace it if it appears to be damaged. The 16 psi

(110 kPa) pressure cap and engine thermostat

work in conjunction with each other to maintain

proper engine cooling.

NOTE: Check the engine temperature lamp every

minute or two after coolant has been changed. Air

pockets can form, and it may be necessary to refill

the cooling system after a short period of use, as

the air naturally bleeds out of the system.

CHANGING HYDRAULIC RETURN FILTER

The hydraulic return filter

element is a cartridge-type

accessible from under-

neath the chassis. Initial

replacement is after the

first 100 hours. Unscrew

the filter cover and

remove. Slide off the old

element and discard.

Insert the new element

onto the housing and

replace the cover.

IMPORTANT: The hydraulic return filter is

equipped with a restriction sensor. If the dash

indicator light comes on, the element should be

replaced.

WARNING

Lower the boom to the ground when servicing

the hydraulic system.

WARNING

Remove the radiator cap only when the engine

is cool, or painful burns could result.

Alternate Transmission

Fill Location

Courtesy of Crane.Market

Loading...

Loading...