50950260/AP1216 57

Stationary Regeneration

Stationary regeneration may be

periodically required to reduce DPF soot

build-up. The frequency of stationary

regeneration is dependent upon machine

operation and engine load.

The machine cannot be used during

stationary regeneration and cannot be

moved without interrupting the stationary

regeneration process.

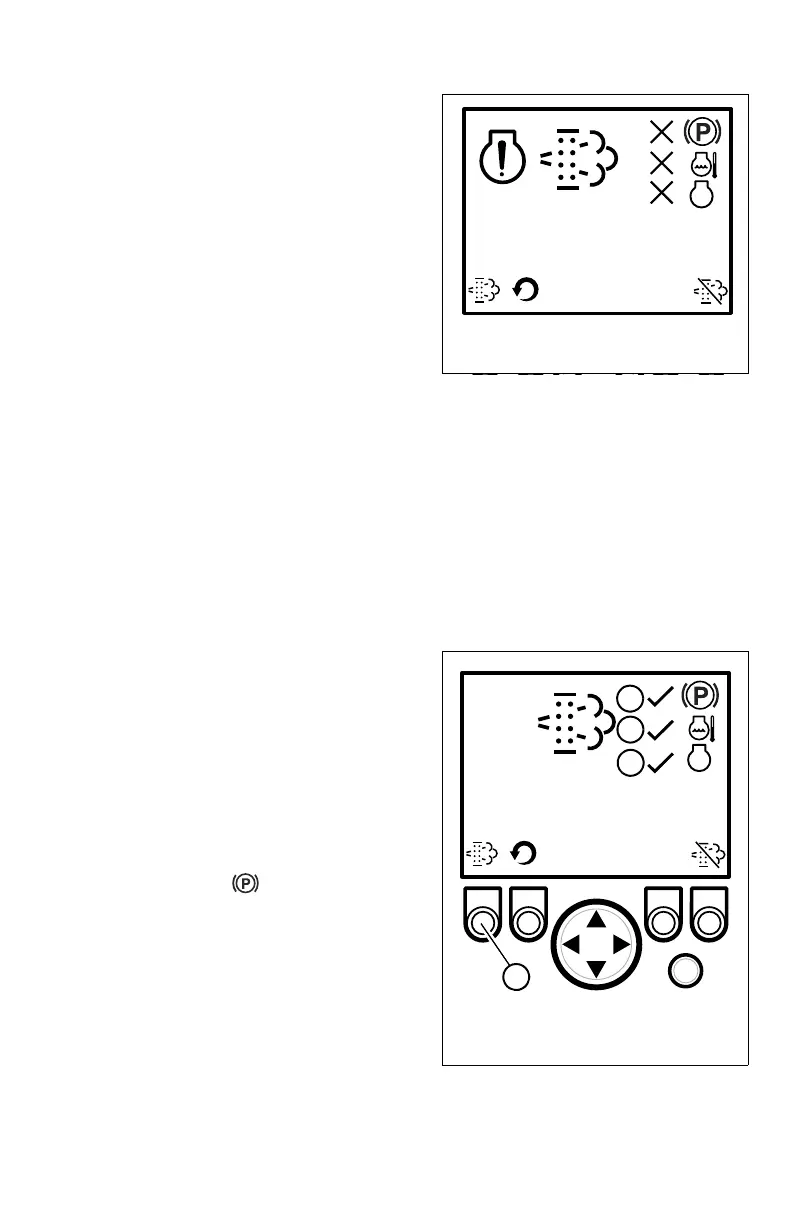

When stationary regeneration needs to be

performed, the regeneration request

screen (Figure 11) displays on the

information center electronic display.

Note: The stationary regeneration request screen can be temporarily dismissed

by pressing the reset regeneration inhibit button (U, Figure 10) for 3 seconds.

Until the previous screen displays. The stationary regeneration request screen

will return 1 minute after being dismissed, for as long as the request remains

active.

Important: Perform stationary regeneration as soon as possible when the stationary

regeneration request screen displays. Postponing stationary regeneration for

extended periods will cause significant reduction in engine power and will force

premature DPF filter core replacement.

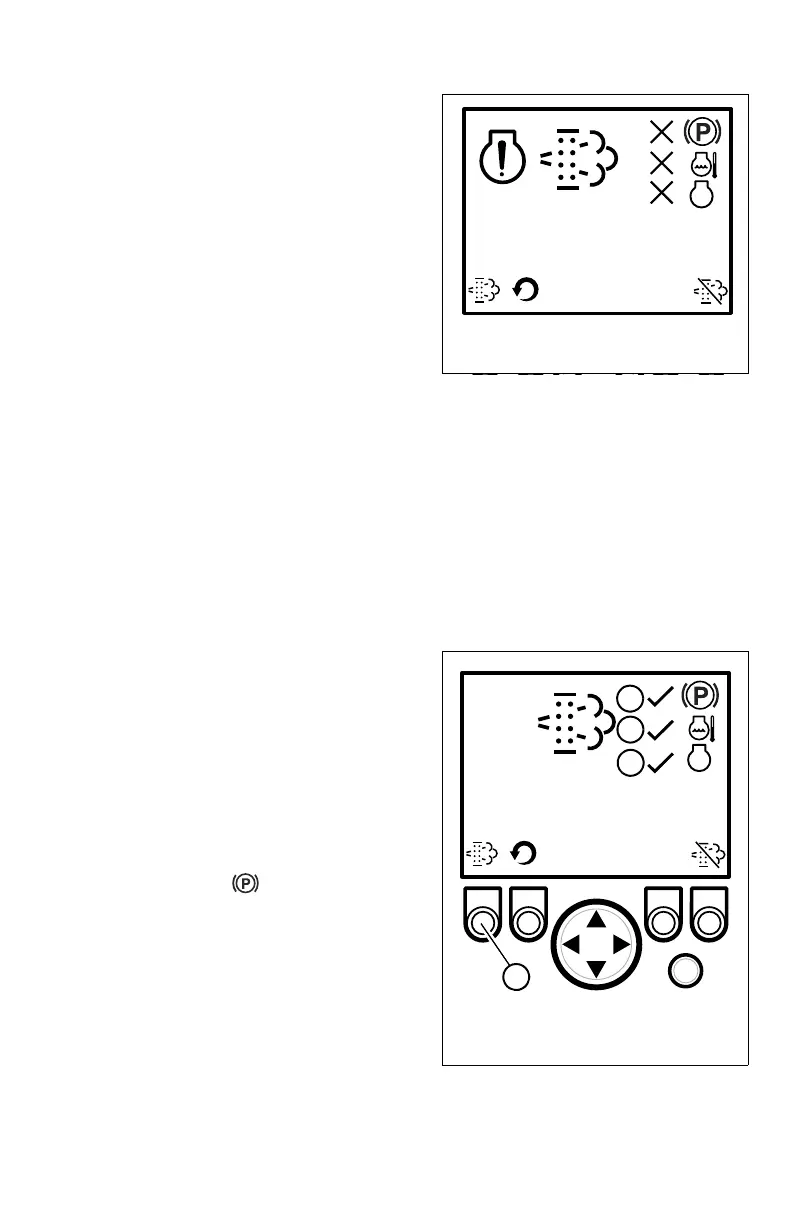

To proceed with stationary regeneration

(Figure 12):

1. Park the machine in a safe, well-

ventilated location away from

flammable materials.

2. The following conditions need to be

met before stationary regeneration

continues:

A. Press the

button on the

control keypad (page 37) or lift

the operator restraint bar to apply

the parking brake. A checkmark is

displayed next to the parking

brake symbol (A).

B. When engine coolant has reached

operating temperature (above

140° F / 60° C, a checkmark is

displayed next to the coolant temperature symbol (B).

n/min

Figure 11 – Stationary Regenera-

tion Request Screen

Figure 12 – Stationary Regenera-

tion

A

B

C

Z

Loading...

Loading...