The Fault relay state in non-fault operating condition is Energized and terminal connections are supplied for Normally Closed and Normally Open. The energized

fault relay setting provides an electrical path for fail-safe relay operation. In the event of any failure, including loss of power, the relay will change to the de-

energized state to indicate a fault condition.

The Fault relay state cannot be reconfigured

Relay Energy State and Terminal Connections

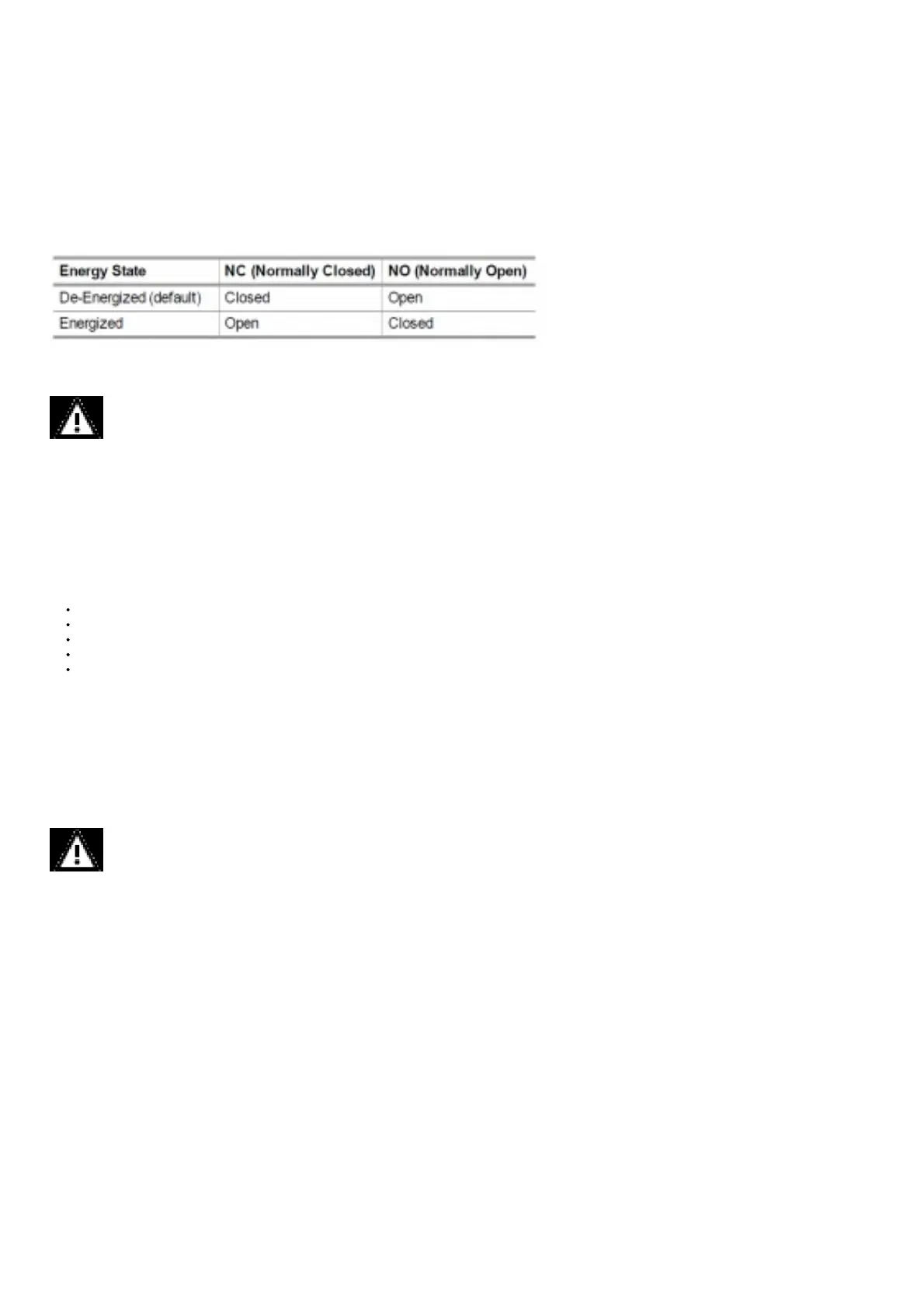

The S5000 relay states are labeled for the default de-energized state. The alarm/warning relay energy state can be changed on the device, which will exchange

the normally open and normally closed terminals. The preferred relay energy state should be determined before making connections. Table 9 shows the terminal

connections by energy state and is

applicable to both relay 1 and relay 2.

Table 9 Relay Terminal Connections by Energy State

4 Operation

WARNING!

Refer to 9 Appendix: General Certification Information before installation and operation.

Failure to follow this warning can result in serious personal injury or death.

The S5000 Series gas monitor is factory calibrated and shipped with the most common default options to minimize set up effort. Using sensors, the device tests

the ambient air and triggers an alarm as soon as the gas exceeds a specific concentration level.

4.1 Startup

4.1.1 Initial Startup

The first time the S5000 is powered on, the following will appear on the display:

S5000

Software Version No.

Sensor Warm-up

Wait

The S5000 will remain in Start-up mode in which the fault relay is de-energized and the analog output is 3.5 mA by default. The time the S5000 stays in Start-up

mode depends on the sensor.

Oxygen and Carbon Monoxide sensors require a 30 minute warm-up time before being fully functional. The device will be in fault during the 30 minute start-up

time. All other sensor start-up times vary, the unit will be in fault for the first 2 minutes of the start-up time and the analog output signal will be at the maintenance

level (3.5 mA default). A full calibration is recommended after one hour of a sensor being installed and acclimated to the environmental conditions. See 5

Calibration for calibration details

4.1.2 Sensor Warm Up Times

WARNING!

For optimal sensor performance, allow sensors 24 hours to acclimate to application conditions before performing an initial calibration

Failure to follow this warning can result in serious personal injury or death.

IR Sensor: ≤ 10 min

H2S: ≤ 5 min

SO2: ≤ 5 min

Cl2: ≤ 10 min

NH3: ≤ 5 min

Cat Bead: ≤ 5 min

Passive MOS: ≤ 5 min

Passive Cat Bead: ≤ 5 min

CO: 30 min (see note)

O2: 30 min

Carbon Monoxide sensor gas codes D10, D11, D12, and D14 may require initial warm-up periods longer than 30 minutes. If the 30-minute warm up is over, the

sensor may show a positive reading that exceeds alarm levels. In the event of a shortterm power outage, the warm-up time for carbon monoxide gas codes D10,

D11, D12, and D14 will be significantly less.

See the table below to estimate required warm-up time.

Table 10 Warm Up Times CO

Loading...

Loading...