inlet for obstructions that could prevent gas from

reaching the sensor. Every six hours, an electrical pulse stimulates the XCell sensor similar to having actual calibration gas applied, providing a snapshot of the

sensor’s sensitivity at the time of the pulse. Using this sensitivity snapshot, the sensor can diagnose sensor failures like electrode poisoning, electrolyte leaking,

or electrical connectivity issues. AEC uses the sensitivity snapshots provided by the pulse check to adjust sensor output, compensating for environmental impacts

on sensor accuracy. If the AEC adjustment is greater than expected based on typical environmental impact variations, the transmitter LED’s will slowly flash

GREEN, alerting users that the sensor should be calibrated to reset the AEC cycle. Users can also enable a Calibration Alert function that will send a milli-amp

signal on the analog output to the control room. The result is a sensor that actively self-monitors for operation and accuracy, with far fewer manual

calibrations. Diffusion supervision actively monitors the sensor inlet for obstructions. If an obstruction is detected, the sensor will go into a fault mode to alert

users and the control room that it is not seeing gas due to an obstruction. Objects residing directly on or in the sensor inlet that result in a significant impact to the

gas path are very likely to be detected by Diffusion Supervision. Examples include paint, tape, water, and dirt. Small amounts of these materials can be visible on

the inlet while not impacting the gas path enough to trigger a Diffusion Supervision Fault. A fault signal will only be sent out when the system determines that the

amount of material that has accumulated on or inside the sensor inlet is negatively affecting the gas path. Actual TruCal sensor performance will depend on the

application, background gas exposure, and environment. To validate XCell sensors with TruCal, it is recommended that users follow their regular calibration cycle

and record the “as found” and “as left” values. This data can be used to extend the time between calibrations depending on the required specification of

the application.

2.8 SafeSwap

The S5000 comes with patented SafeSwap technology, which allows users to change or replace XCell sensors without needing to power down the instrument.

Swap delay is enabled on the S5000 by default; a feature that gives users a 2 minute window to change sensors without triggering a fault condition. SafeSwap

and Swap Delay are only applicable for XCell sensors. For more information on SafeSwap and Swap Delay, see 6 Maintenance.

WARNING!

As part of the product certification, it was verified that optional communication functions of this gas detection instrument while operating at the maximum

transaction rate do not adversely affect the gas detection operation and functions of the instrument. The product certification, however, does not include or

imply approval of the SafeSwap feature, communications protocol or functions provided by the software of this instrument or of the communications

apparatus and software connected to this instrument.

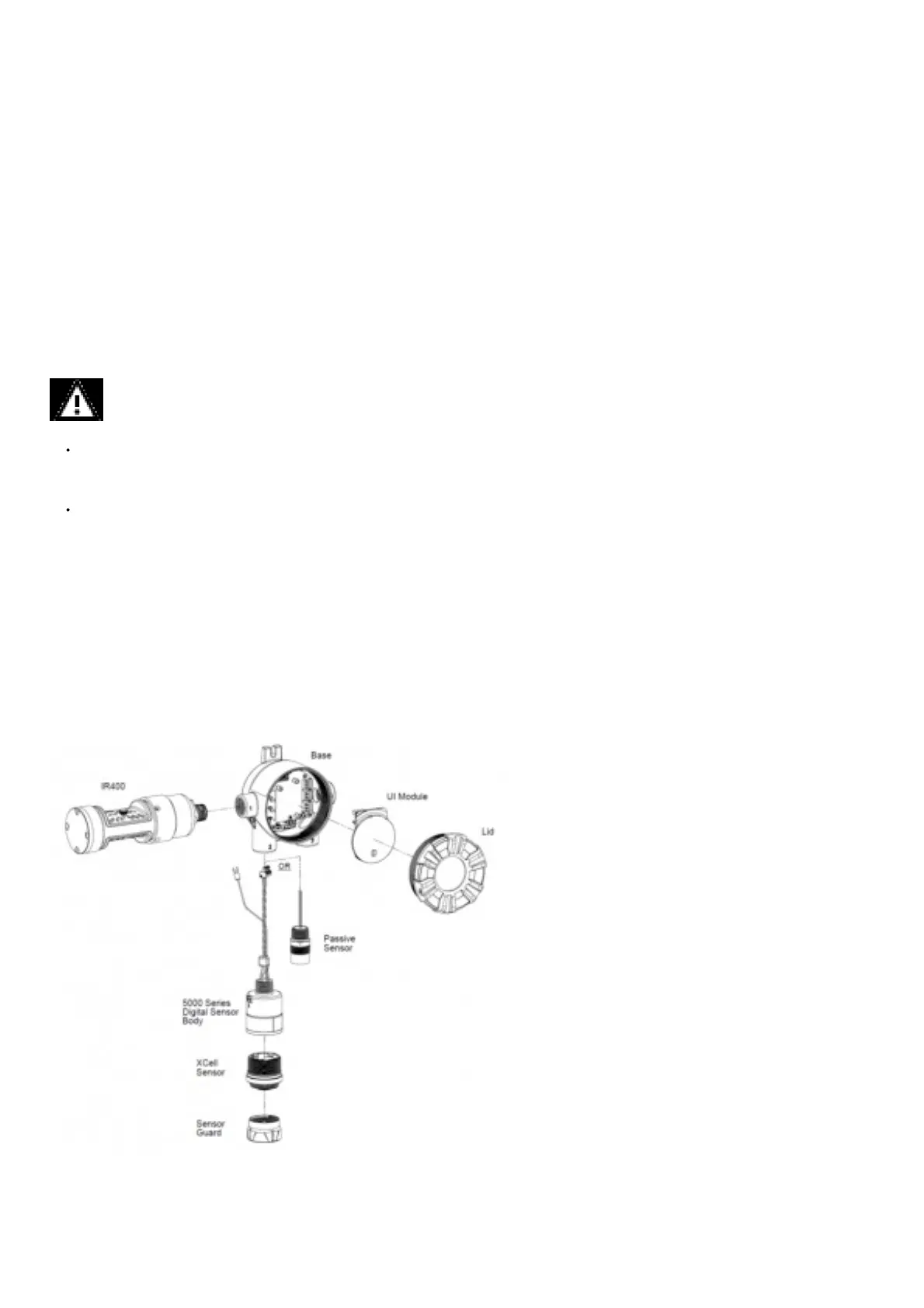

Follow the warnings below when removing or replacing sensors. Reference Figure 3 for component overview.

– Never remove or replace a Sensor Body Assembly or an IR Sensor while under power or when explosive hazards are present.

– Confirm that the area is free of explosive hazards before removing or replacing an XCell Sensor under power.

– To remove an XCell Sensor, unscrew XCell Sensor three full turns, wait 10 seconds, and then remove the XCell Sensor completely.

Failure to follow these warnings can result in serious personal injury or death.

2.9 Housing

The S5000 comes in 316 Stainless Steel for the highest corrosion resistance. All housings have ¾” NPT conduit entries. Custom tags are available and easily

attach to an integral ring. The JB5000 junction box comes in 316 Stainless Steel for the highest corrosion resistance. The housing is offered in ¾” NPT of M25

conduit entries.

2.10 Component Overview

Figure 3 Exploded View

2.11 Label Overvi

Loading...

Loading...