recommended that the first sensors be calibrated more often to establish the sensor performance in this particular environment. For this, record the “as found”

and “as left” values and track the percent adjustment over time. Then, gradually extend calibration intervals until the percent adjustment is greater than the

expected accuracy of the sensor.

5.3 Calibration Frequency for XCell Sensors with TruCal (H2S & CO only)

WARNING!

Certain conditions may prevent the performance of Diffusion Supervision and/or TruCal testing. If such a condition persists for 90 days, the XCell sensor with

TruCal will recommend a calibration which is communicated through the transmitter display and LEDs. When Calibration Alert is enabled, the milli-amp signal

output will also be driven to calibration alert

output. Perform a calibration when the device recommends it.

Failure to follow this warning can result in serious personal injury or death.

5.3.1 XCell Sensor with TruCal and Diffusion Supervision (CO&H2S Only)

Sensors with TruCal technology will adjust sensitivity without any manual intervention or calibration, unless called for by the sensor. If the adjusted sensitivity from

TruCal deviates too far from the last gas calibration sensitivity, the sensor will recommend or, in extreme cases, require a calibration. When a calibration is

recommended, the transmitter LED status indicators slowly pulse green. Users can also enable a Calibration Alert function that will send a milli-amp signal on the

analog output to the control room when a calibration is recommended. When a calibration is required, the status LEDs will flash yellow and the transmitter will go

into a Calibration Required Fault. With Diffusion Supervision and Calibration Alert enabled, the time between scheduled calibrations can be extended to 24

Months. If calibration alert and/or diffusion supervision are disabled follow the calibration frequency recommendation set forth in

5.3.2 XCell Sensor with TruCal without Diffusion Supervision (CO&H2S Only).

5.3.2 XCell Sensor with TruCal without Diffusion Supervision (CO&H2S Only)

Sensors with TruCal technology will adjust sensitivity without any manual intervention or calibration, unless called for by the sensor. If the adjusted sensitivity from

TruCal deviates too far from the last gas calibration sensitivity, the sensor will recommend or, in extreme cases, require a calibration. When a calibration is

recommended, the transmitter LED status indicators slowly pulse green. Users can also enable a Calibration Alert function that will send a milli-amp signal on the

analog output to the control room when a calibration is recommended. When a calibration is required, the status LEDs will flash yellow and the transmitter will go

into a Calibration Required Fault. Without Diffusion Supervision, regular calibration of the sensor must still be conducted to confirm the sensor inlet is not

obstructed. Actual TruCal sensor performance will depend on the application, background gas exposure, and environment. To validate

XCell sensors with TruCal, it is recommended that users follow their regular calibration cycle and record the “as found” and “as left” values, tracking the percent

adjustment over time. Once a baseline is established, the calibration intervals can be extended until the percent adjustment is greater than the expected accuracy

of the sensor.

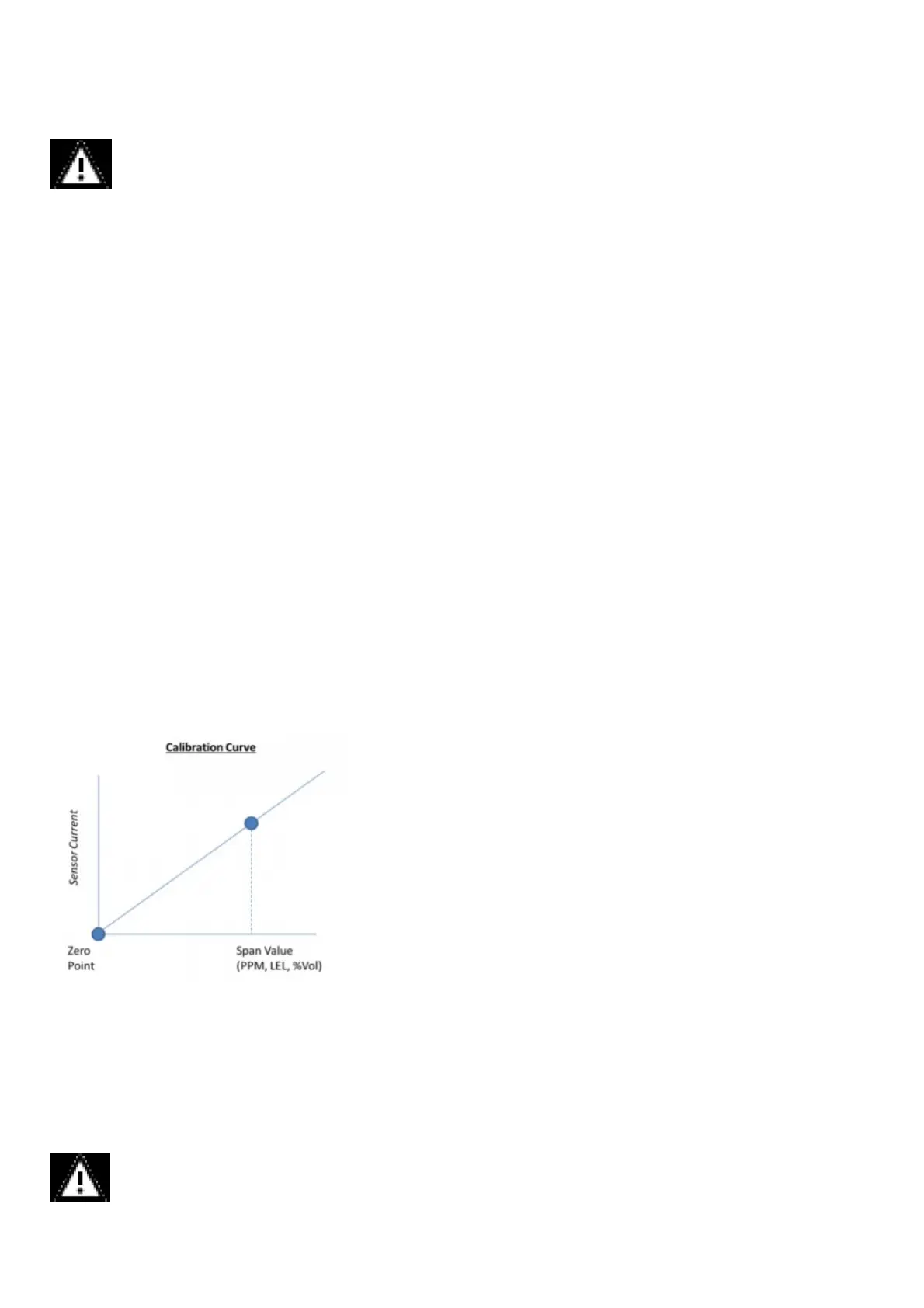

5.4 Calibration Types: Zero vs. Span

There are two types of calibration; zero and span calibration. The zero calibration resets the baseline level reading to zero. If the target gas is suspected to be

occasionally present, it is

best to also use a zero gas cylinder during the zero calibration. If the target gas is not present in the atmosphere, an additional calibration cylinder is not required.

The span calibration is a process that involves first zeroing the baseline reading, then applying a known amount of target gas so that the accuracy and precision

of the transmitter can be adjusted to the known value. The known concentration of gas is called a “Span Value” because it represents the span or reach of the

calibration curve from zero to that value.

The Sensor Span Value (i.e. Cal Level) in the device menu should be the same as the concentration listed on the calibration gas cylinder.

5.5 How to Zero Calibrate XCell and IR Sensors

NOTICE If a password is enabled, you will not be able to proceed with the calibration without the password.

To abort, press the EZ touch button or apply magnet over GM logo before applying target gas. In the event that a calibration cannot be completed, the user can

acknowledge the FAIL by pressing the EZ touch button or applying magnet to the GMI logo area until “Reset” is displayed and then release. The unit will revert to

the settings of the last successful calibration.

WARNING!

The regulator used with the zero gas cylinders should not be the same as the regulator used for the target gas. The zero gas regulator can be contaminated with

the target gas over time, and thus raise the detection baseline and make the sensor less sensitive to the target gas.

Loading...

Loading...