inspect the window to ensure that the entire surface is clean.

5. The device will go into a “Cleaning required” fault with an analog output of 2.0 mA when cleaning is needed. The S5000 analog output may go down to 1.25

mA while the optical path is blocked, and display will indicate “Beam Block”.

While in “Beam Block” fault, the sensor will not respond to the presence of gas

6. When cleaning is done and the objects are removed from the sensor window, the device returns to normal operation. If water or isopropyl alcohol was used,

allow the device to operate for 15 minutes to completely dry before replacing the sensor guard continuing to monitor for combustible gas.

7. Replace the sensor guard.

When the cleaning process is complete, be sure to remove all objects from the light path. It is recommended to check the sensor’s response to zero and

calibration gas after cleaning.

WARNING!

Do not place foreign objects in the sensor’s analytical region (except per the “S5000 IR Sensor Cleaning Procedure” as described above); otherwise, the infrared

beam can be partially blocked, causing the sensor to generate false readings. All objects must be removed from the sensor’s analytical region for it to function

properly.

Failure to follow this warning can result in serious personal injury or death.

6.2 Replacing an XCell Sensor

The only routine maintenance item is the sensor, which has a limited lifetime. The S5000 sensors with TruCal technology will indicate when the sensor is near

end of life through the Status Menu. When the Sensor Life & Health status is “Fair”, there is approximately 2 month time frame to replace the sensor before it will

no longer function. Actual time between “Fair”

status and sensor end of life depends on exact environmental conditions. When a TruCal sensor is no longer capable of sensing it will go into fault and LEDs will

flash yellow. It is good practice to obtain a replacement sensor before the sensor within the unit becomes inoperative. There is no need to open the main

enclosure. Simply unscrew the sensor assembly located on the bottom of the main assembly.

WARNING!

Do not disassemble the sensor assembly. The sensing element inside may contain hazardous material.

Handle the sensor carefully; the electrochemical version is a sealed unit which contains a corrosive electrolyte.

Any leaked electrolyte that comes in contact with skin, eyes or clothes can cause burns.

If any contact with the electrolyte does occur, immediately rinse with a large quantity of water. On contact with the eyes, rinse thoroughly with water for 15

minutes and consult a doctor.

Do not install a leaking sensor in the sensing head assembly.

A leaking sensor must be disposed of in accordance with local, state and federal laws.

As part of the product certification, it was verified that optional communication functions of this gas detection instrument while operating at the maximum

transaction rate do not adversely affect the gas detection operation and functions of the instrument. The product certification, however, does not include or

imply approval of the SafeSwap feature, communications protocol or functions provided by the software of this instrument or of the communications

apparatus and software connected to this instrument.

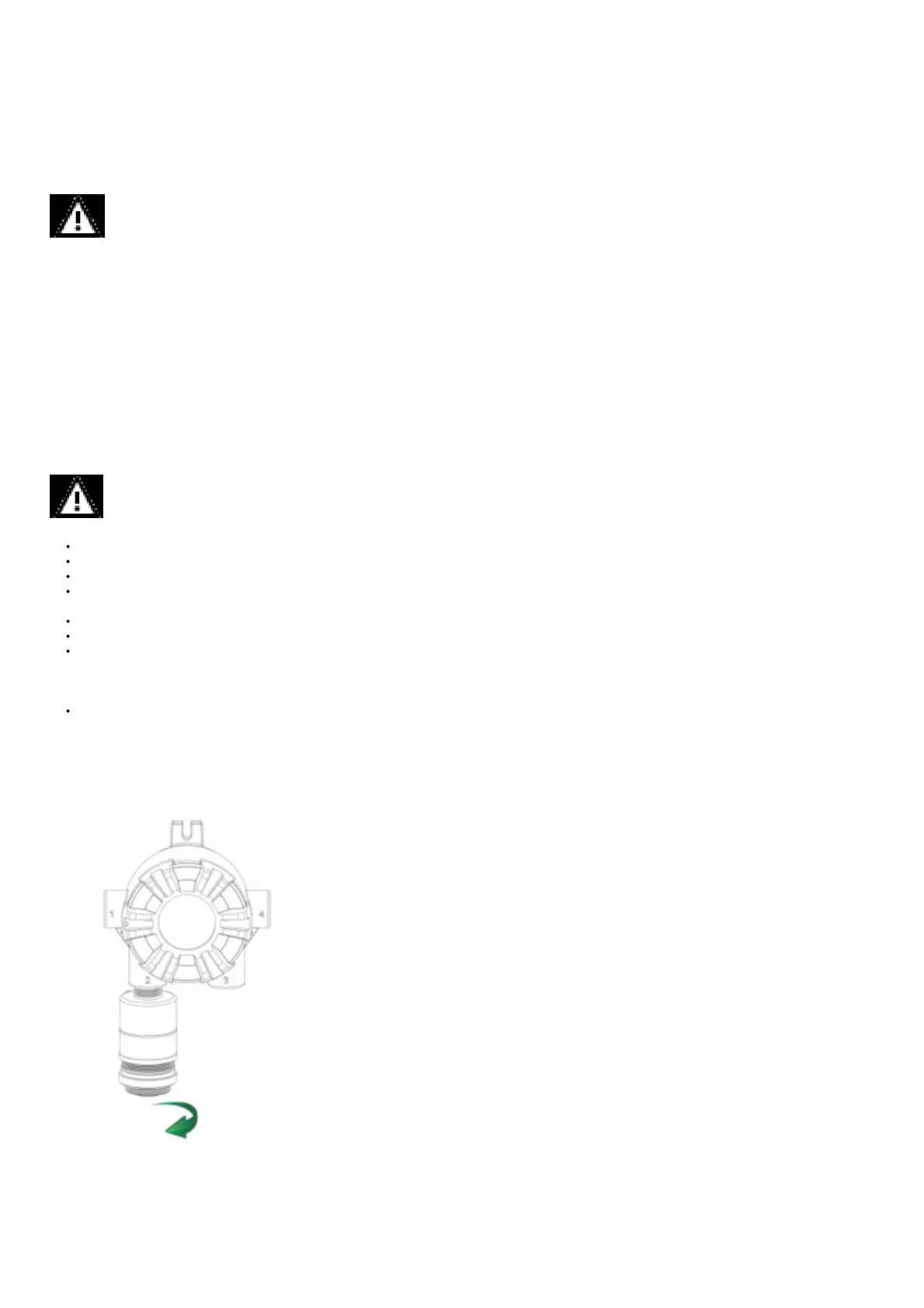

Follow the warnings below when removing or replacing sensors. Reference Figure 3 for component overview.

– Never remove or replace a Sensor Body Assembly or an IR Sensor while under power or when explosive hazards are present.

– Confirm that the area is free of explosive hazards before removing or replacing an XCell Sensor under power.

– To remove an XCell Sensor, unscrew XCell Sensor three full turns, wait 10 seconds, and then remove the XCell Sensor completely.

Failure to follow this warning can result in serious personal injury or death.

Identify the sensor assembly needed via the A-5K-SENS code on the interior sensor label and obtain the appropriate sensor assembly; replace sensor assembly.

Figure 33 Removing the XCell Sensor

Loading...

Loading...