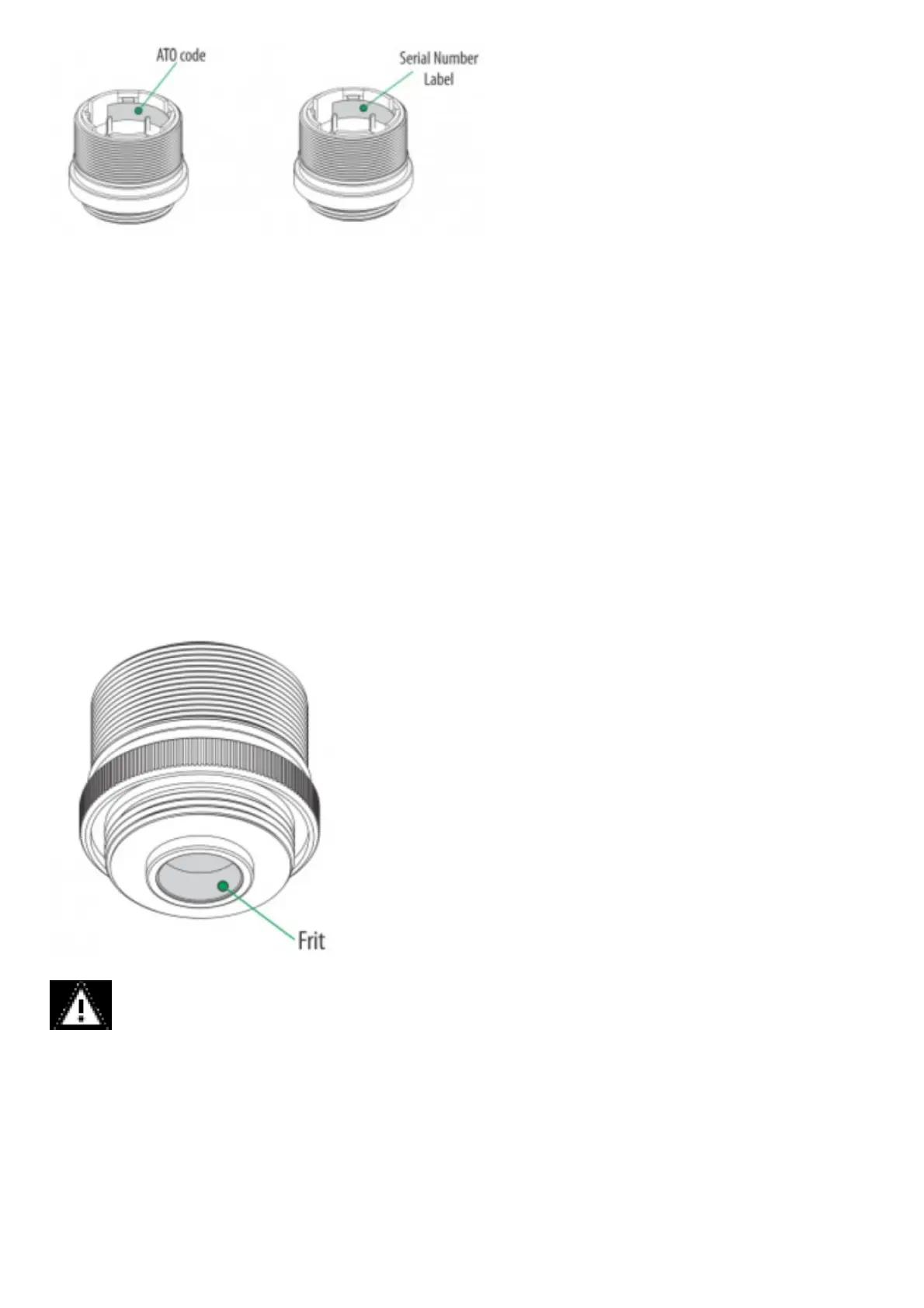

Figure 34 Digital Sensor – Position of Labels

Alarm set points, span value, full scale limit and alarm direction will not change when replacing a sensor with the same gas type. Alarm set points, span value, full

scale limit and alarm direction will change to the new sensor’ settings when replacing a sensor with a different gas type.

The S5000 Gas Monitor is shipped with the Sensor Swap Delay enabled. IF enabled, the 4-20 mA output signal goes to 3.5 mA and the FAULT relay will hold off

a fault indication for 2 minutes. This setting allows the operator to exchange sensor modules without a FAULT indication.

It is recommended that all other maintenance be performed at an MSA factory-authorized service center.

6.3 Clearing a Blockage

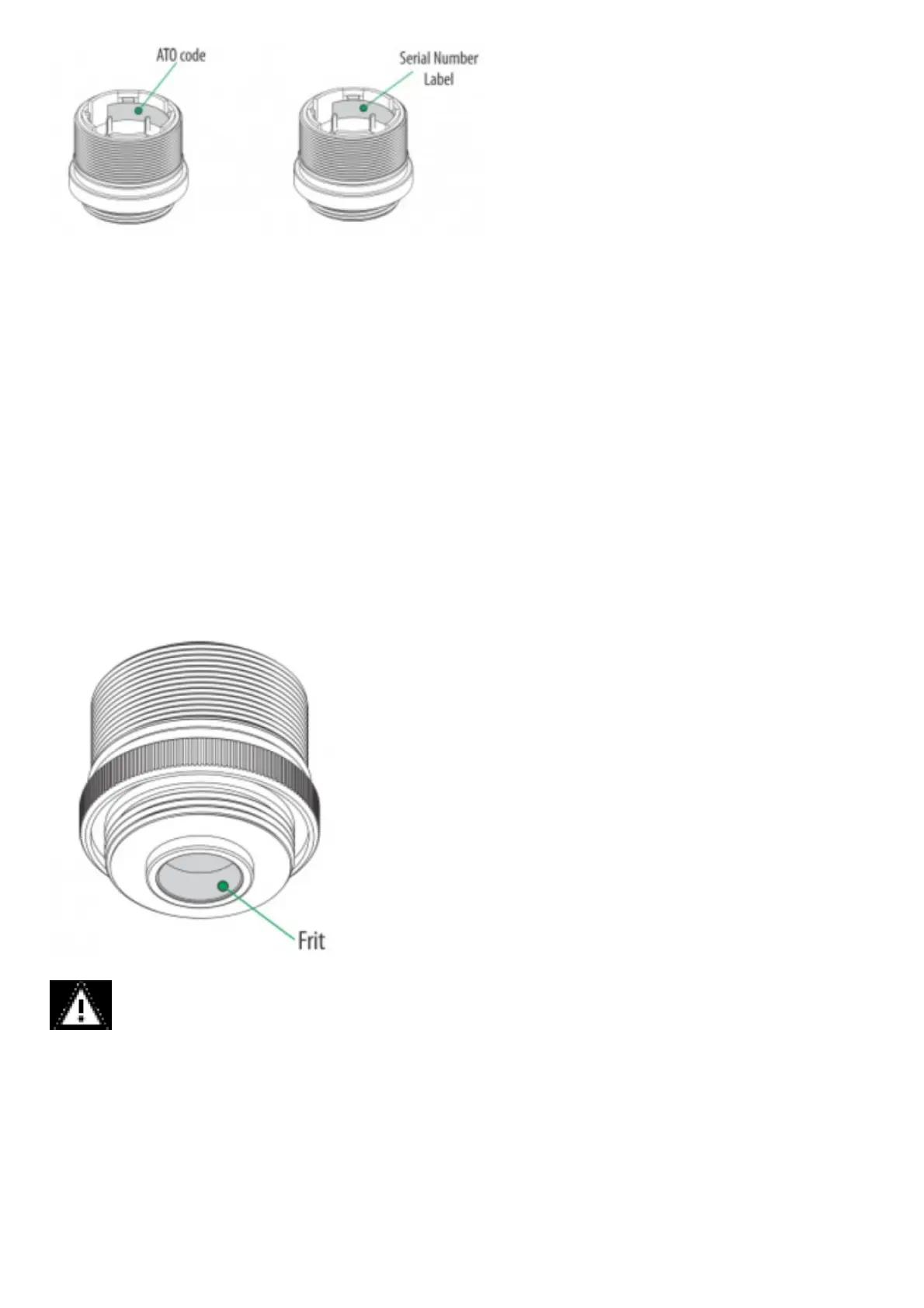

If using a Digital Sensor with Diffusion Supervision, and if the Diffusion Supervision feature has been enabled in the Sensor Settings, the sensor will notify the

user if it detects foreign material obstructing the sintered metal frit where gas would normally enter the sensor (see Frit Location). When this condition is detected,

the transmitter will go into fault and show “Diffusion Supervision Fault” on the display. Follow these recommended steps to attempt to clear this fault:

1. Inspect and clear the sensor inlet and frit.

2. Inspect and clear any accessories attached to the sensor.

3. Ensure Sensor is fully mated to the Sensor Body Assembly.

4. Attempt to recalibrate the Sensor.

5. Disable Diffusion Supervision or replace the Sensor.

First, with the sensor still installed, visually inspect the sensor to see if any objects are covering the gas inlet and remove them. Example objects may include

tape or the green Calibration Cap. Next, check to make sure that there is no foreign material stuck to the frit. If any material is found, gently remove it while

considering any hazards that may arise from such

an action, like the accumulation of a static charge, and taking the necessary steps to avoid them. Take care to ensure that the frit is not damaged during the

cleaning process. DO NOT use water or liquids to try to clean the frit. The frit acts like a sponge and will retain liquids, which will keep the gas path blocked.

WARNING!

The sensor relies on the frit as a part of its Flameproof/Explosionproof approval. If the frit is damaged while attempting to clean it, immediately remove power

from the device. Ensure the area is free of a hazardous atmosphere, then follow all steps as outlined in this manual to properly replace the sensor. Failure to

follow this warning can result in serious personal injury or death.

If no material is visible, the frit may still be blocked by a liquid which has absorbed into the frit. Once absorbed, liquids are very difficult to remove. For these

situations, relying on natural evaporation is recommended. Due to the time it can take for liquids to evaporate sufficiently from the frit, users may want to consider

swapping out the affected sensor with one that is

known to be clear. Placing absorbent material against the outer surface of the frit can help accelerate this process.If a sensor is in Diffusion Supervision Fault, the

device will still allow the user to attempt to calibrate the sensor. In the rare event that a sensor calibration is successful, but the Diffusion Supervision system

continues to detect a blockage in the gas path, the Diffusion Supervision Fault will return in approximately 24 hours. In this scenario, there is likely an

environmental factor affecting the Diffusion Supervision detection. Provided the sensor can successfully calibrate, the sensor is still capable of detecting gas. To

prevent the Diffusion Supervision Fault from reoccurring, a user can either disable Diffusion Supervision in the Sensor Settings (see 4.2.2 Sensor Setup) or

replace the sensor.

Loading...

Loading...