3.6.4 Power Load Requirements and Maximum Mounting Distances)

If these requirements are met, performance of the S5000 should meet the noise immunity standard equivalent of the S4000CH, S4000TH, and TS4000H

using the existing wiring; However, the installation may not meet the latest EMC EN50270 noise immunity standard that the S5000 meets with the grounding

and wiring scheme as indicated in this manual

and corresponding I/O drawing.

3.6.3 Electrical Hardware Requirements

Braided shielded, twisted pair, instrument quality wire or cable should be used to minimize the possibility of noise interference and contact with other voltages.

Selection of shielded cable must comply with local requirements. Conduit, in addition to braided shielded wire, may also be needed in areas where a large

amount of electrical noise is

expected. All cable shields should be terminated to earth ground at one end only. The S5000 has a four-wire power terminal, one four-wire communication

terminal, and three four-wire sensor terminals. Relays can be added as an option. Terminals for power and relays can take wires up to 12 AWG while all other

terminals take wires up to 14 AWG. Four conductors are also required for the S5000 remote junction boxes.

Incoming power and signal cables should be a braided shield cable such as Alpha Wire 3248 or equivalent. The braided shield must be terminated to the board

stack as shown in Figure 27 , or alternatively, the earth ground at the user’s power source location.

An external Class 2 power supply is required to supply 12-30 VDC to the S5000. Incoming power and signal cables should be a braided shield cable such as

Alpha Wire 3248 or equivalent.

3.6.4 Power Load Requirements and Maximum Mounting Distances

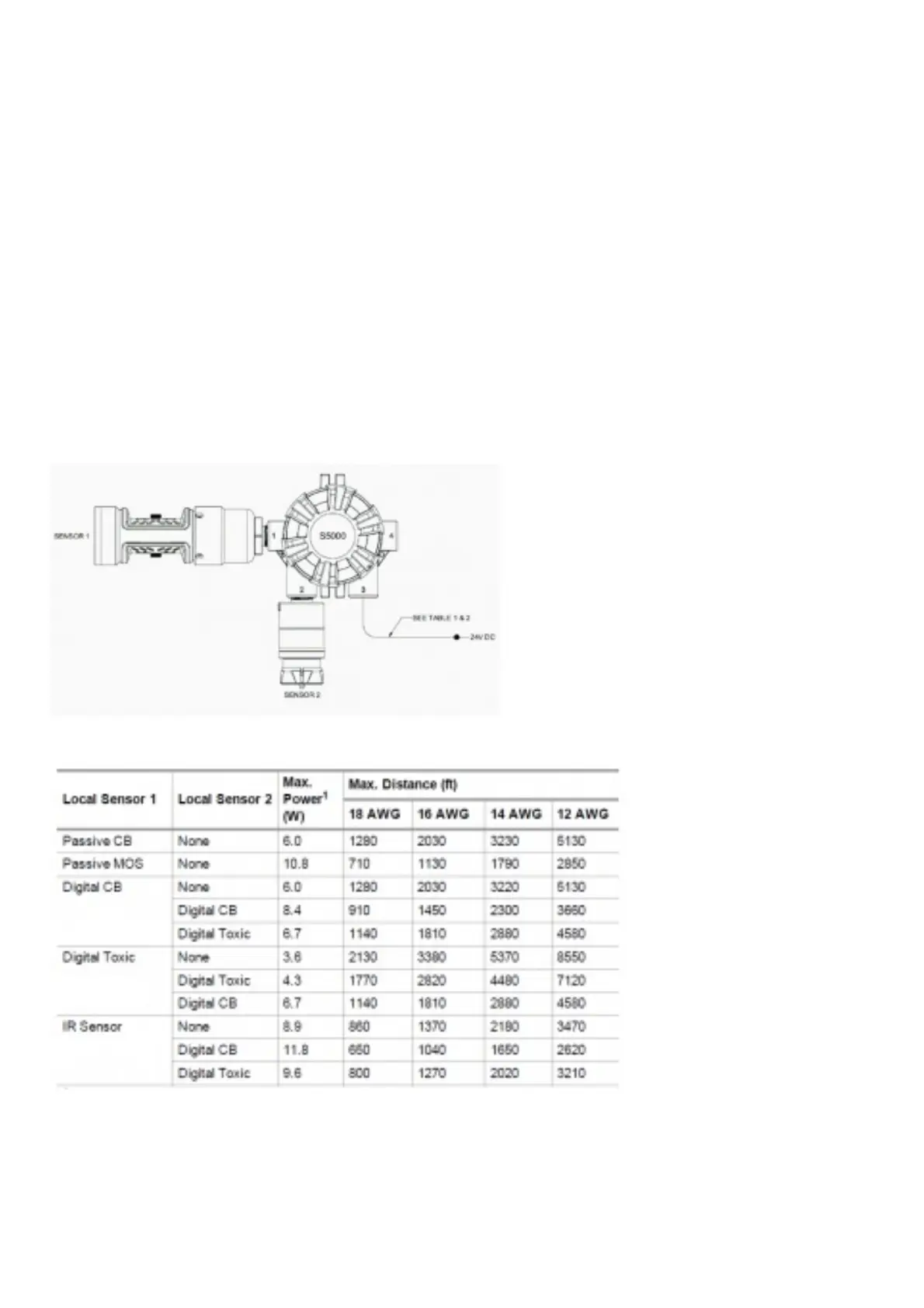

Consider future needs when selecting cable size and power supply. The maximum distance between the S5000 transmitter and the power supply depends on the

sensor configuration (sensing technology and one or two sensors), wire gauge, and the power supply voltage. The table below outlines the maximum transmitter

mounting distances. First determine if the

sensor(s) will be locally or remotely mounted. Then choose sensor type(s). The corresponding maximum power and mounting distances by wire gauge are

shown.

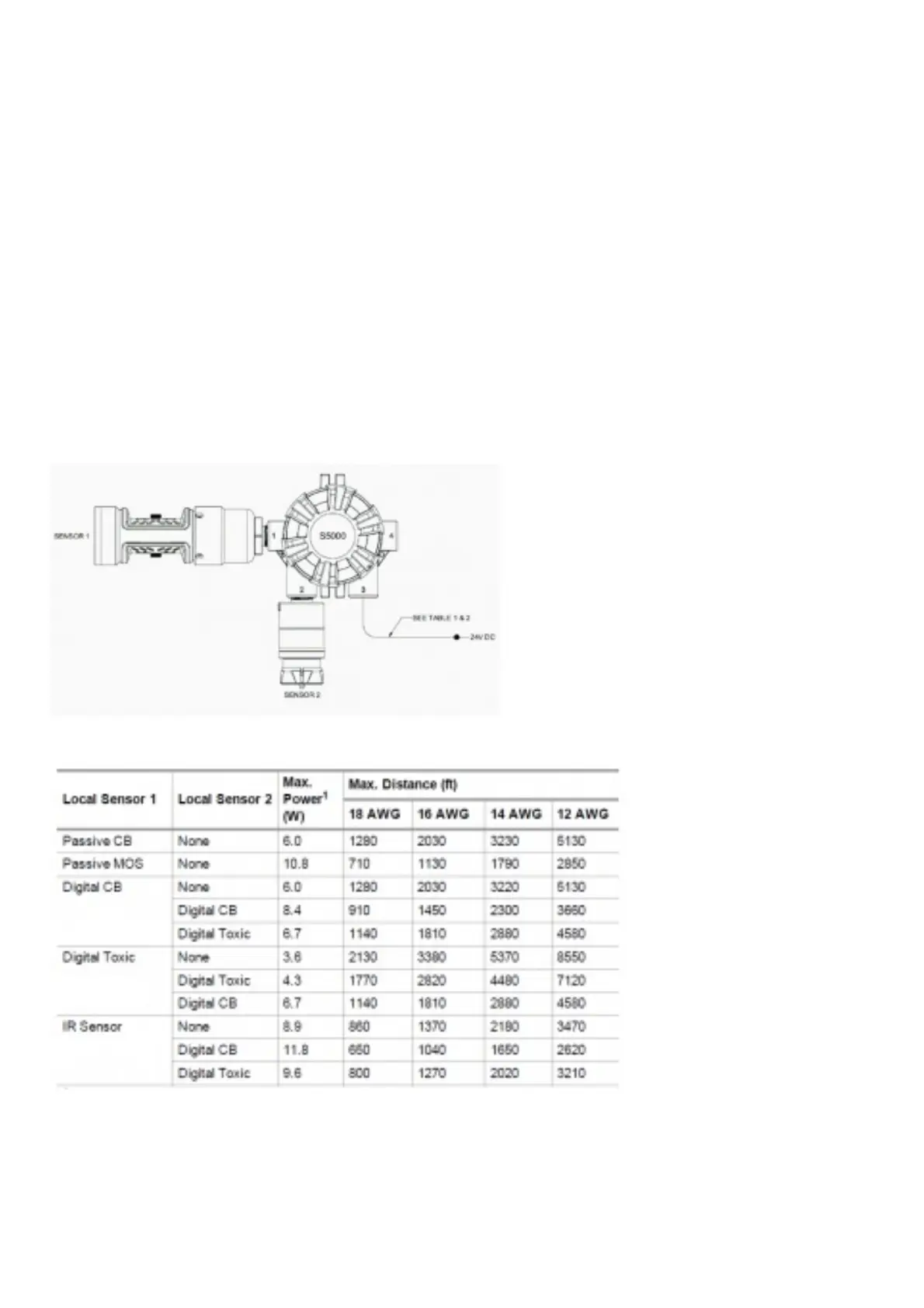

Figure 24 Local Sensors

Table 1 Maximum Mounting Distance for Local Sensors, Imperial Units

1- When sizing a system’s 24 V supply, a 1 A inrush current with a 1 ms duration should be considered for each device on the power supply

Assumes transmitter was ordered with relays

Table 2 Maximum Mounting Distance for Local Sensors, Metric Units

Loading...

Loading...