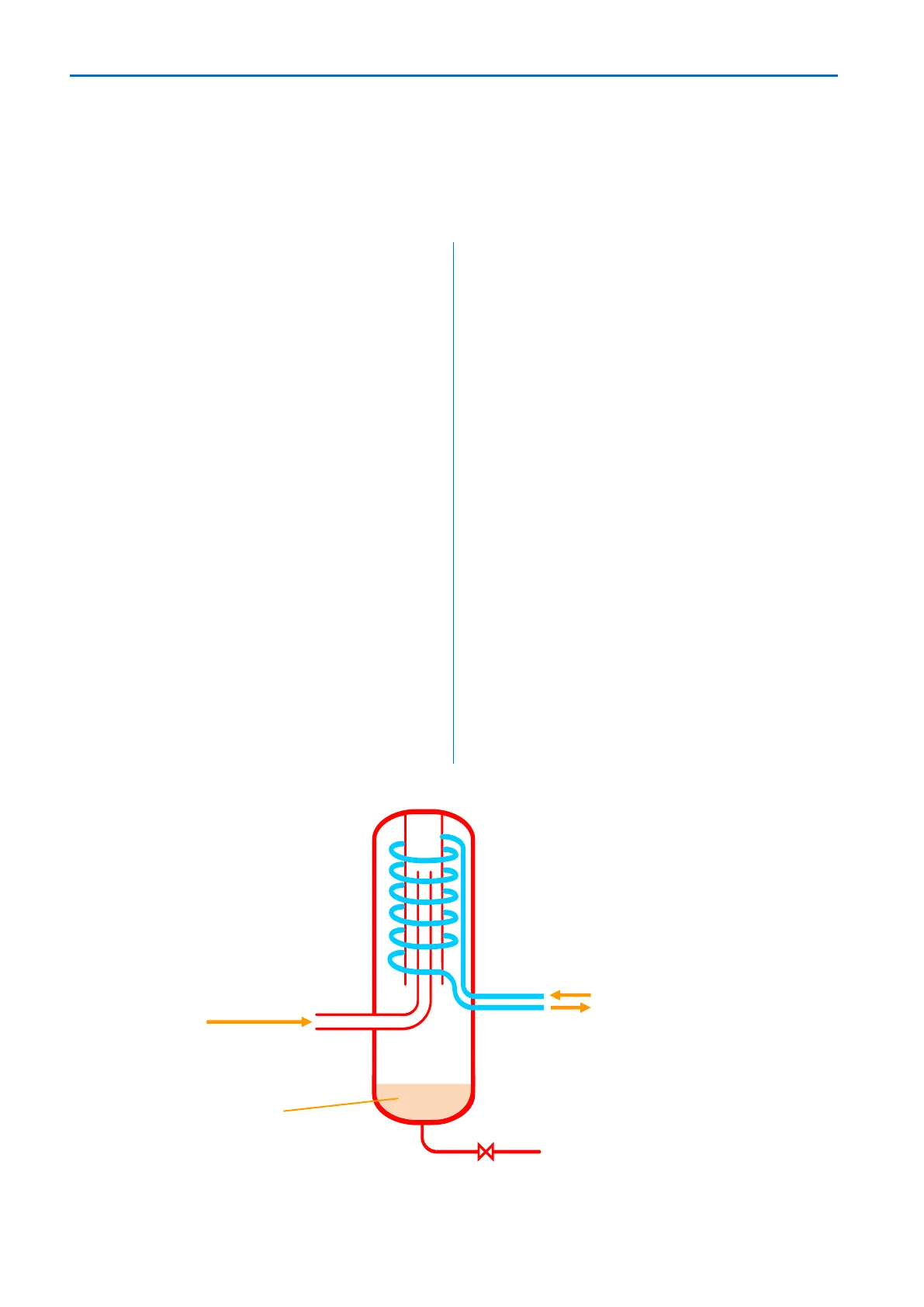

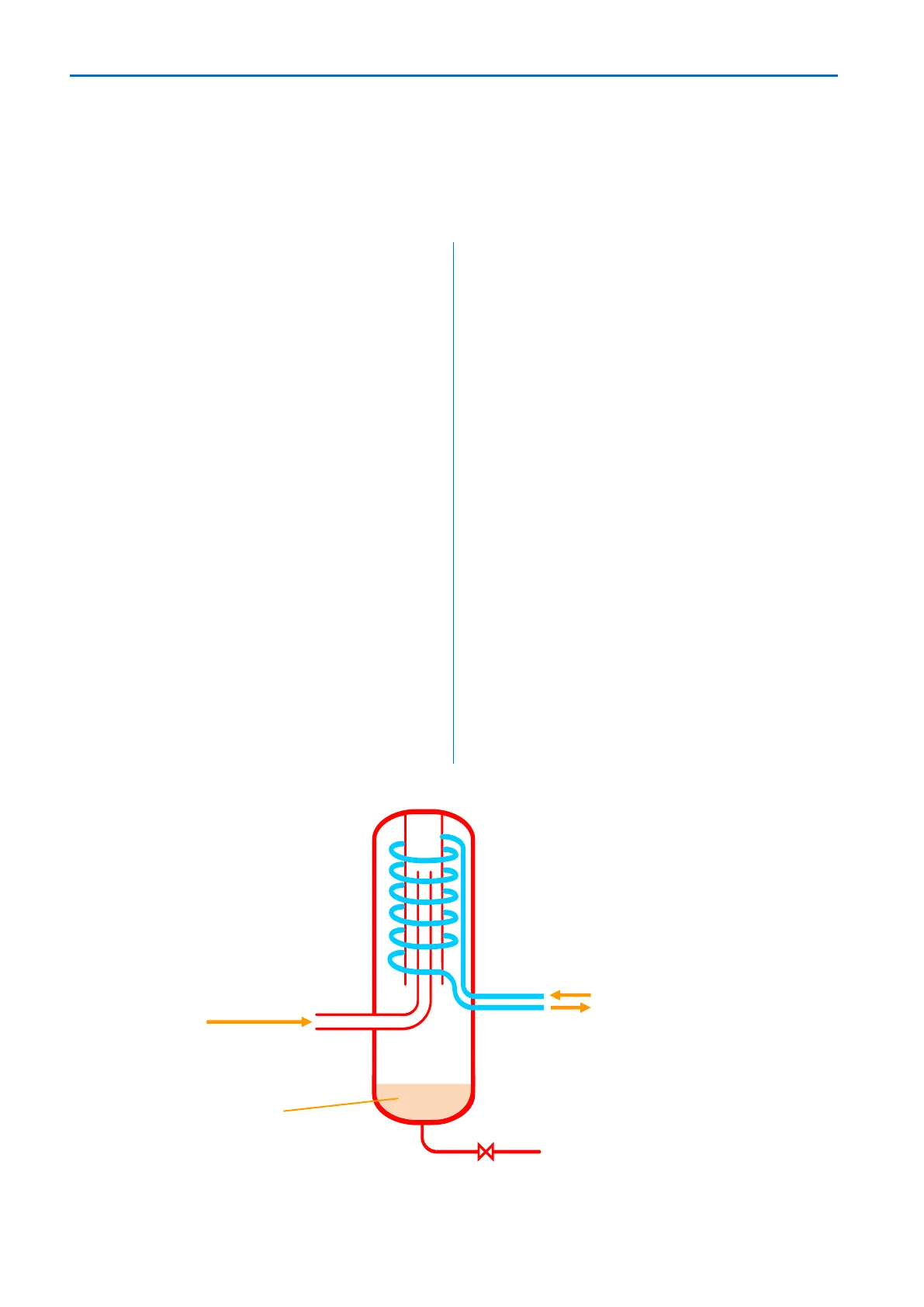

Condensing power is provided by coolant

from a re-circulating chiller which is

remotely controlled by the Rocket 4D to

maintain optimum coolant temperature at all

times.

To ensure efficiency of the recirculating

chiller, the coolant level must be topped up

using use a mixture (50% water, 50% mono

ethylene glycol) and the chiller must be set

to remote control mode. Refer to the chiller

operating manual for details.

The Rocket 4D software monitors the

temperature of coolant entering the

condenser and compares it to the

temperature of coolant leaving the

condenser.

The difference (∆T) equates to the heat

energy transferred from the evaporated

solvent to the condenser and is proportional

to the flow rate of solvent vapour entering

the condenser. As samples approach

dryness, the reduction in ∆T is used to

determine the auto stop trigger point.

Coolant stabilisation

External effects are likely to cause uneven

heat distribution within the coolant circuit

when the system is not in use, this can

affect ∆T stability for a period after the

evaporator is switched on. To allow time for

stabilisation, the system does not attempt to

set the end of stage trigger point during the

first five minutes of operation.

Loading...

Loading...