Rocket 4D Evaporation System

56 04-7848 Issue 2-4 August 2014

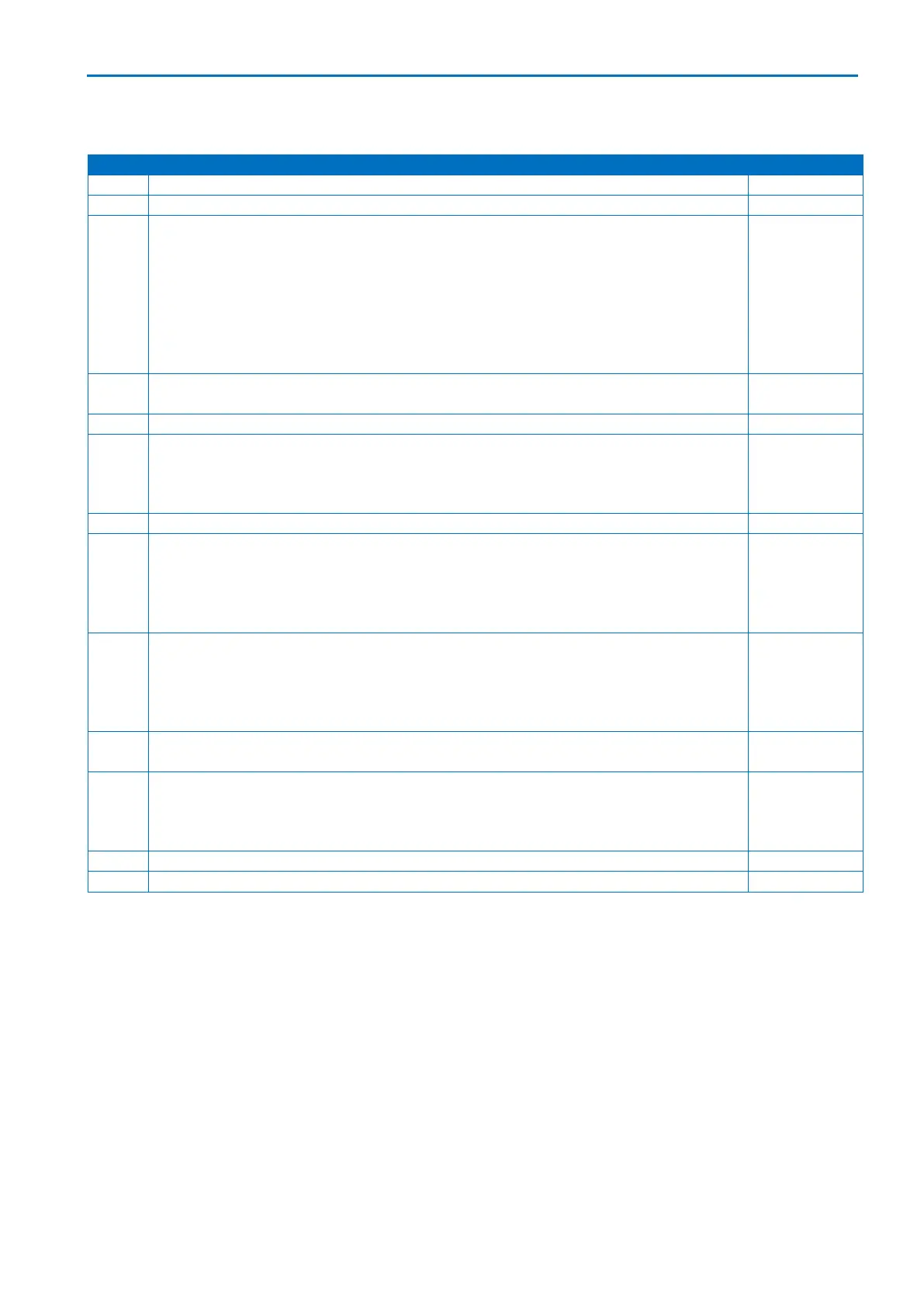

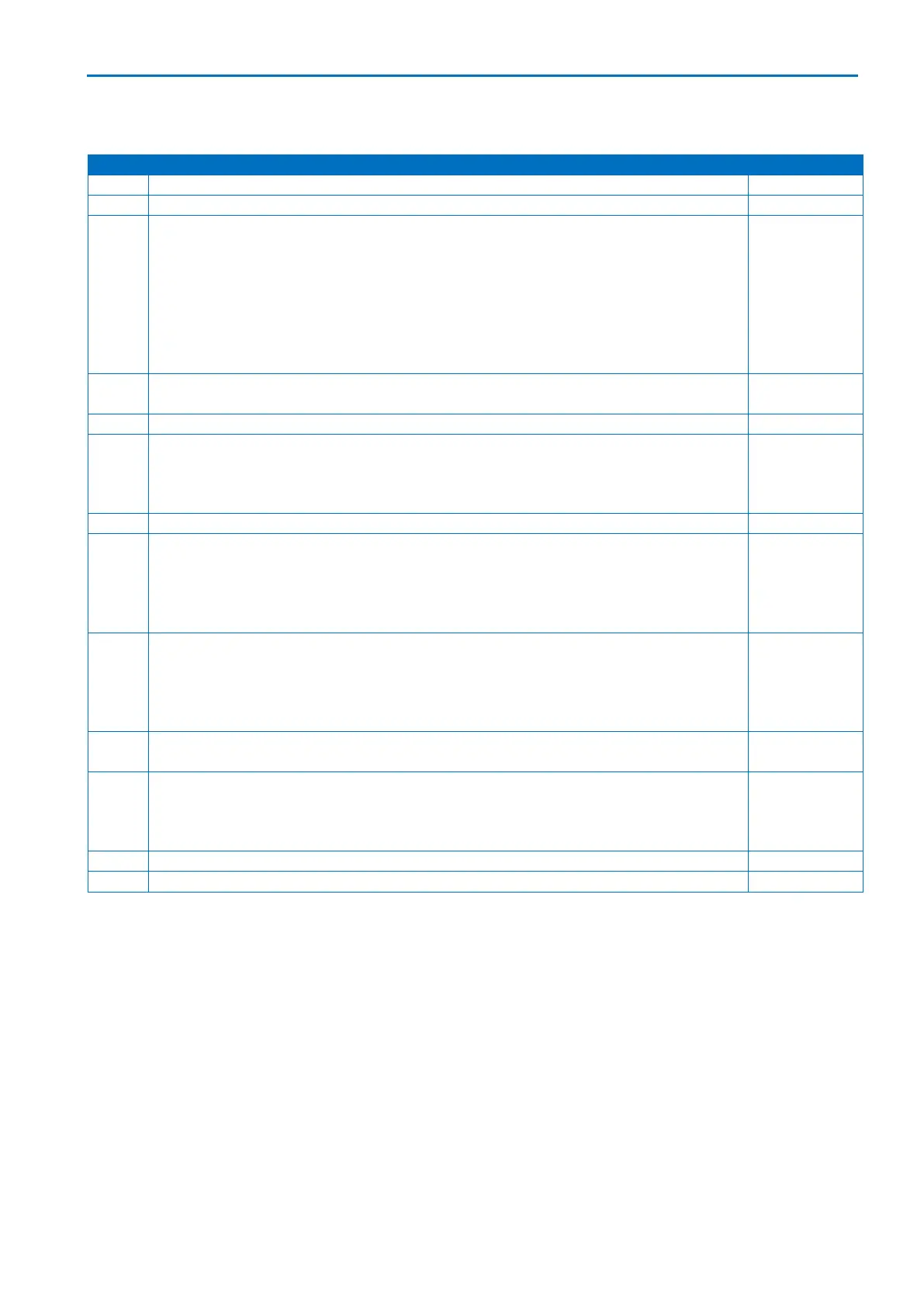

Amendment control

First release for 4D demonstration trials.

First release for 4D production units.

Rotary joint bleed change to rotary joint purge. Stainless steel evaporation

vessel - caution added. Distribution Connector change inner lid feed. Bowl

rotor change to evaporation vessel. Rotary joint PTFE liners added to

consumable parts list. Rotary joint added to Maintenance. Specifications

updated. Infinity trolley option introduced. Illustrations updated.

Troubleshooting reviewed. R&D amendments. Rocket 4D Declaration of

Conformity issued. Emergency shutdown instruction added. Acceptable

Solvents updated. Pre-heat evaporator for DMF- instruction added.

Pouring stand instructions moved to Options, part number and entrapment

warning added.

Additional instructions for vacuum integrity errors.

Specifications amended: pump dimensions, store upright, dimensions do not

include allowance for hose and cable connections. Feed system option

includes batch functionality. Waste solvent recovery optimised custom

method, note added. Set-up instructions: feed system only.

US contact address updated.

nXDS6 replaced XDS5. Pouring spout details added. Method separated in

Acceptable Solvents table. Single / Mixed solvent feed sequence moved to

Method Overview. Spares and accessories part number tables added. EC

Declaration of Conformity updated. Type “D” or equivalent, replaces type

“D”.

Inner lid seal: EPDM blue replaces black Viton. Seal kit part numbers

included in Ordering Spares. Ingress protection rating specification added.

Coolant flow rate and max inlet pressure spec and warning added. 15 A

power cable introduced for supply 2 on 120 V systems. Max coolant inlet

pressure specification revised.

Pouring stand added to accessories. Images revised to show two-port-cap.

Layout revised and Introduction simplified (to align with Rocket).

Overview format revised. Power-up instructions revised. Screen shots

revised. Manu overview revised. Acceptable solvents table revised.

Condenser optimisation diagram revised. Special methods replaces custom

methods. DoC updated.

Waste solvent drain / vent orientation corrected.

Specification for operating environment humidity revised.

Loading...

Loading...