Rocket 4D Evaporation System

48 04-7848 Issue 2-4 August 2014

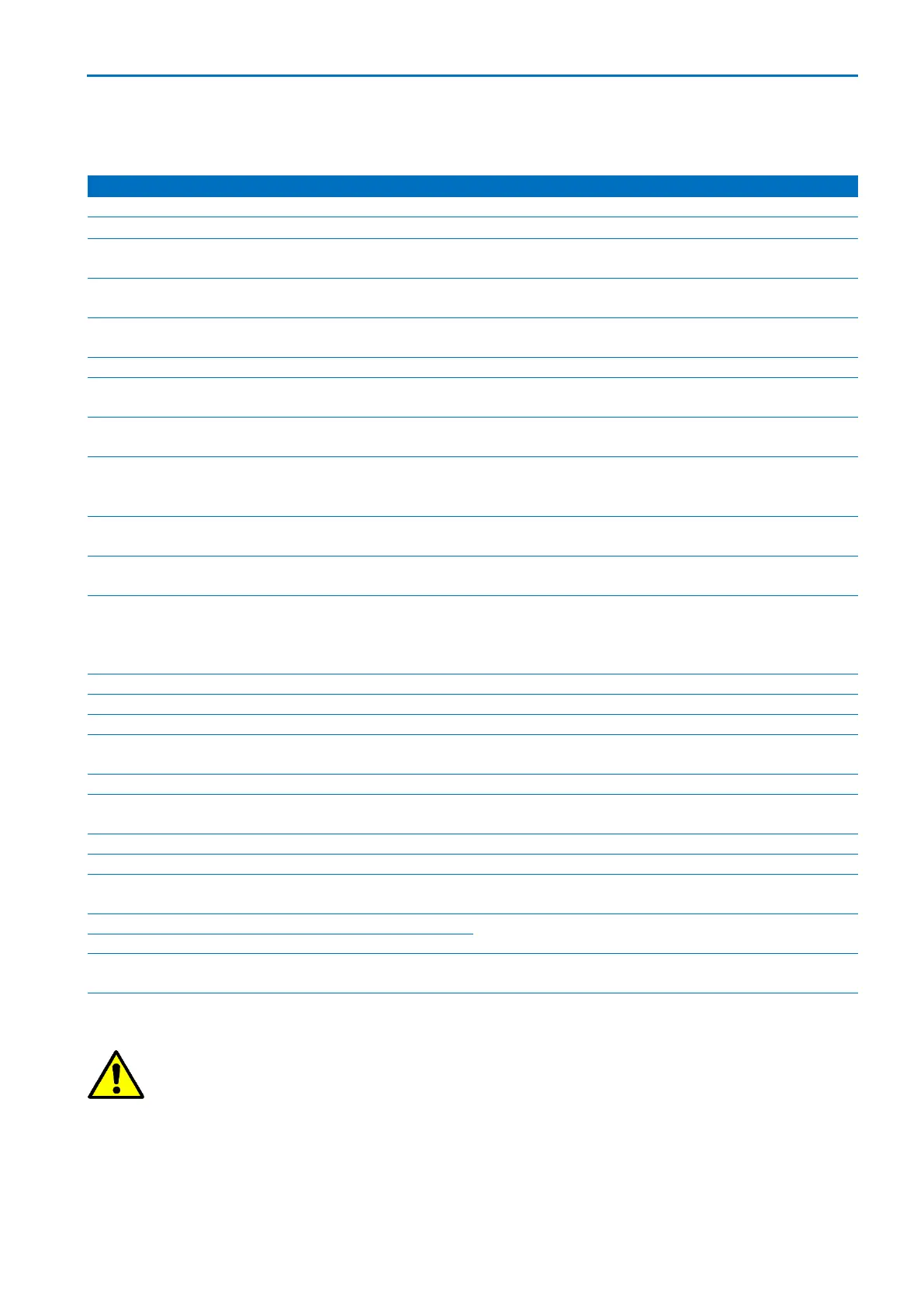

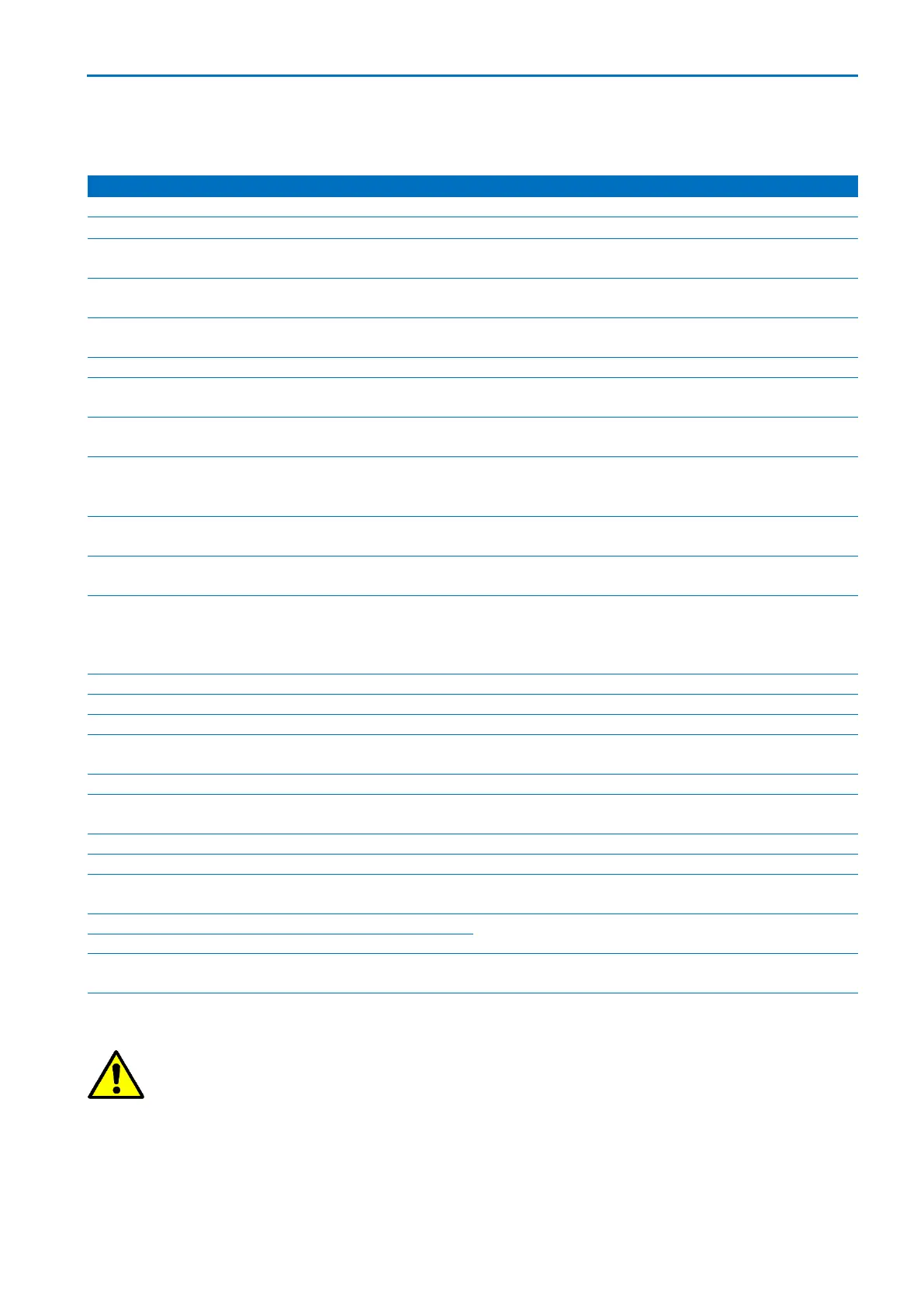

Error rectification

Make sure lid is closed and engaged with latch

No lid open detected between starts

Fail vacuum start up test

Check outer lid seal / close lid firmly / push down

on the lid at the back

Rotor does not reach full speed

Check rotor is free to rotate

Check chamber water reservoir is not overfull

Motor overheat (may occur after

excessive start / stop cycles)

Check inner lid seal is intact / check feed

coupling is intact

Check shaft hub O-ring

Refit inner lid

Fail to reach control pressure

Check appropriate method is selected / check

feed hoses are correctly fitted / check pump

ballast is set to position 1

Coolant too cold for aqueous

Reset chiller to remote or set coolant

temperature to >+2°C

Interruption to secondary power supply

Check secondary power cable is connected to

service panel and power is switched on

Insufficient solvent evaporated during

the last two stages

Decant product solution from evaporation vessel

(or select batch mode to evaporate product

solution from evaporation vessel). Check

correct method is selected and restart.

System is syphoning liquid

Check / clean feed valves

Push down main lid to ensure it is fully closed

Low ∆T (insufficient solvent load)

Check feed system / check pump ballast is set

to position 1

Supply voltage out of range

Check mains supply voltage

Check data key route folder (see Advanced

Features, File transfer)

Check coolant (level and mixture)

Vacuum leak - atm to outer

Vacuum leak - atm to inner

Check pump ballast is set to position 1 / check

feed system / check rotary joint

Vacuum leak - inner to outer

Check rotor hub O-ring / check inner lid seal /

check lid coupling

Vacuum leak - outer to inner

Re-circulating coolant level low (error

only flagged if comms lead connected)

Refer to Julabo user manual / contact Julabo

Service

Caution: the inner lid thumb screw can be damaged by over tightening; when

checking the integrity of the vacuum system, do not over tighten. See: Opening

the lid.

Instructions for rectification are given where user rectification may be possible. If error

codes occur that are not listed, or if the suggested rectification does not resolve the

problem, contact your Genevac distributor for further advice.

Non-critical errors clear automatically. To clear other error messages, once the cause has

been established and rectified, press the stop button. Fuses

Loading...

Loading...