CAUTION!

Risk of injury due to recoiling lever!

Levers under spring tension may cause injury.

Therefore:

– Use caution when working on levers under spring tension.

– Keep at a safe distance.

Environmental

protection

Observe the following environmental information when performing maintenance:

Remove any used, excess or exiting grease from all lubricating points that are manually supplied with

lubricant and dispose of the grease as required by all applicable local regulations.

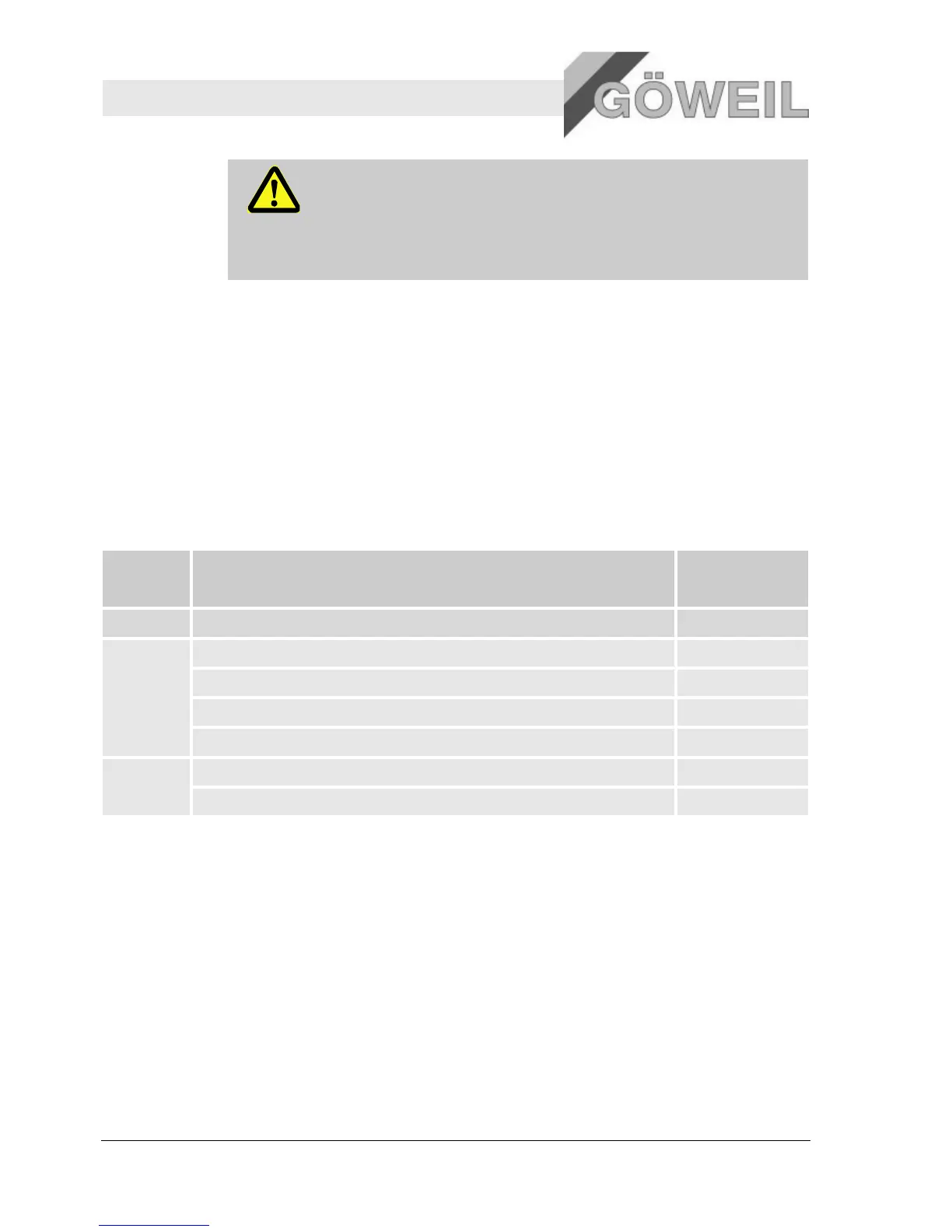

8.2 Maintenance schedule

The following sections describe maintenance steps that need to be performed to allow the machine to operate

trouble free and at its full capacity.

If regular inspections reveal an increased level of wear, the maintenance intervals must be shortened in

accordance with the actual wear detected.

For questions about maintenance steps and intervals, please contact the manufacturer or an authorized dealer.

Interval

(Bh – hours

of operation)

Maintenance step To be performed by

General

Prior to every

use

Remove any foreign objects and contamination. Operator

Movability of components Operator

Condition of the cup grinding wheel Operator

Wear on the cup grinding wheel Operator

annually Lubricate the pilot bearing of the rotary unit. Operator

8.3 Maintenance steps

8.3.1 Lubricating joints

Other required protective equipment:

Protective gloves

Loading...

Loading...