Risk of fire, poisoning, and health damage caused by lubricants!

Lubricants may ignite when coming into contact with sources of ignition.

Contact with oil and grease may cause

No open fire during work on the machine.

Do not inhale oil or grease fumes.

Avoid skin contact with oil and grease.

Immediately clean the skin of all oil and grease.

8.4 Lubrication chart

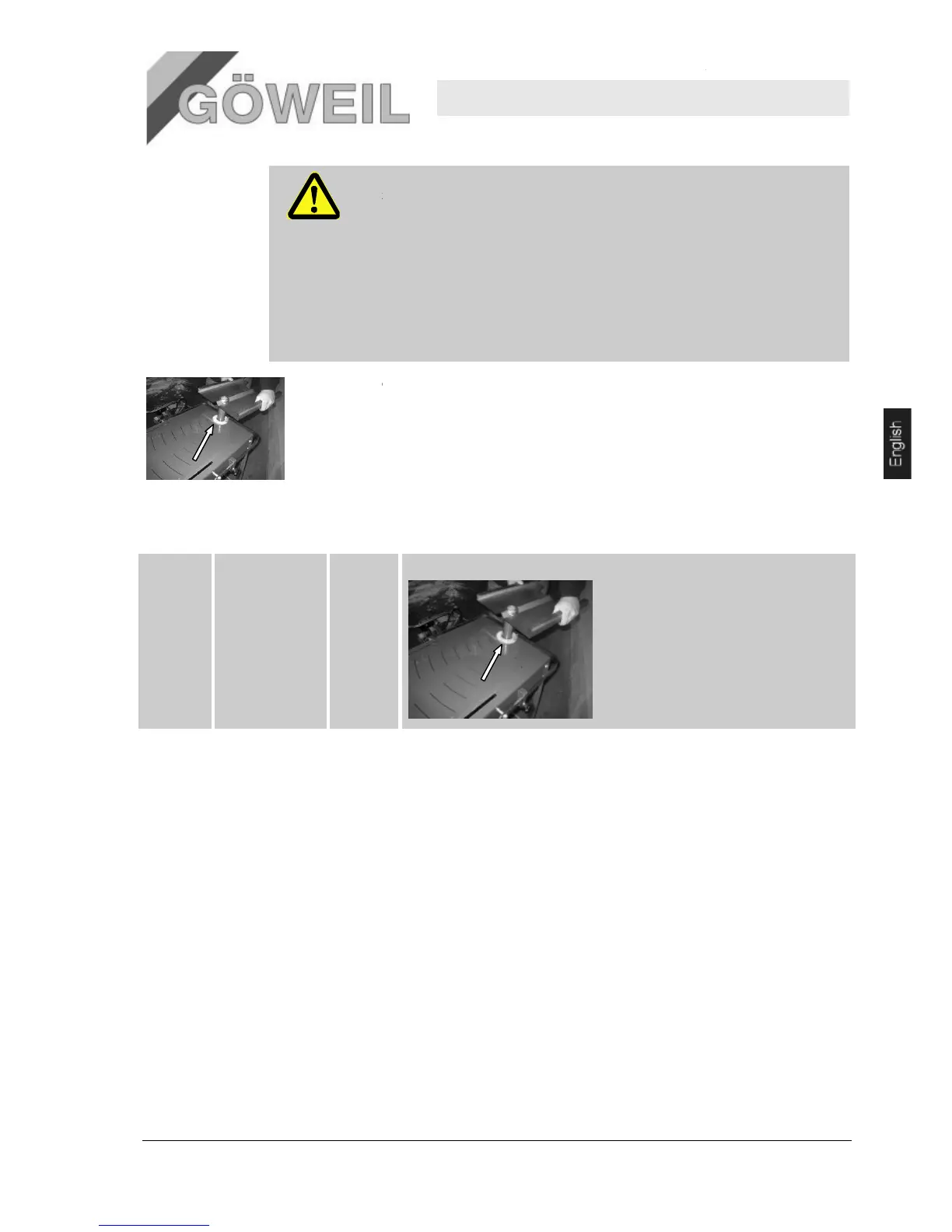

annually Pilot bearing of the

rotary unit

Steps after maintenance is

Pos: 9.33 /KN2006-SM /Wartung/0 09 1.1.0 Massn ahmen nach erf olgter Wartung --> St andard @ 9\mo d_114443898 1309_1.doc @ 86 935

Proceed as follows when maintenance is complete and before switching the machine back on:

Check if all previously loosened

Check if all previously removed safety fixtures and covers have been properly reinstalled.

Make sure that all tools, materials and other equipment used have been removed from the work area.

Clean the work area and remove any le

Ensure that all safety fixtures of the machine function properly.

Risk of fire, poisoning, and health damage caused by lubricants!

Lubricants may ignite when coming into contact with sources of ignition.

Contact with oil and grease may cause

damage to a person's health.

No open fire during work on the machine.

Do not inhale oil or grease fumes.

Avoid skin contact with oil and grease.

Immediately clean the skin of all oil and grease.

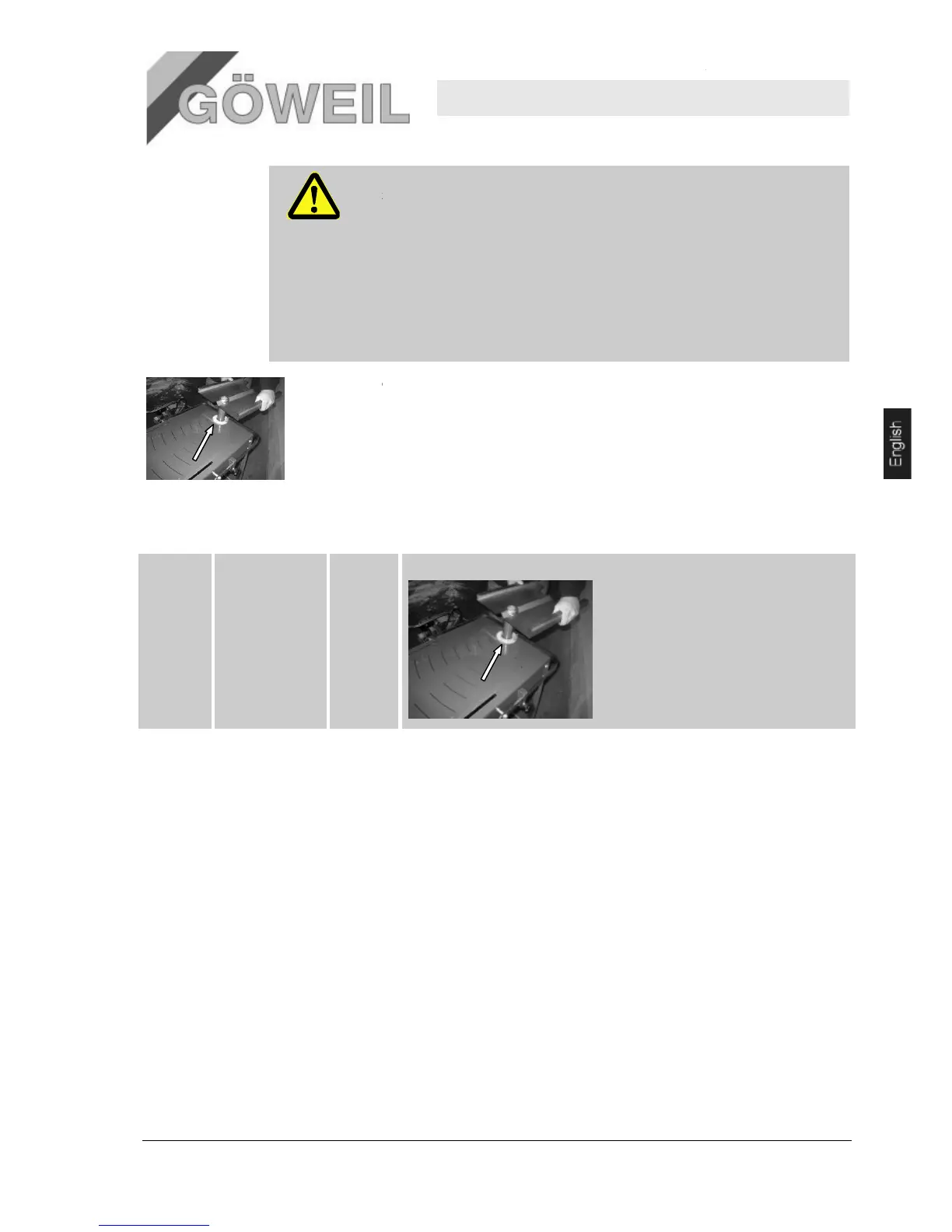

bearing of the rotary unit on the grinding machine has to be lubricated with standard

Clean the pilot bearing first!

Steps after maintenance is

Proceed as follows when maintenance is complete and before switching the machine back on:

Check if all previously loosened

screw connections are tight.

Check if all previously removed safety fixtures and covers have been properly reinstalled.

Make sure that all tools, materials and other equipment used have been removed from the work area.

Clean the work area and remove any le

aked materials such as liquids, process materials or similar

Ensure that all safety fixtures of the machine function properly.

Risk of fire, poisoning, and health damage caused by lubricants!

Lubricants may ignite when coming into contact with sources of ignition.

damage to a person's health.

bearing of the rotary unit on the grinding machine has to be lubricated with standard

Proceed as follows when maintenance is complete and before switching the machine back on:

Check if all previously removed safety fixtures and covers have been properly reinstalled.

Make sure that all tools, materials and other equipment used have been removed from the work area.

aked materials such as liquids, process materials or similar

Loading...

Loading...