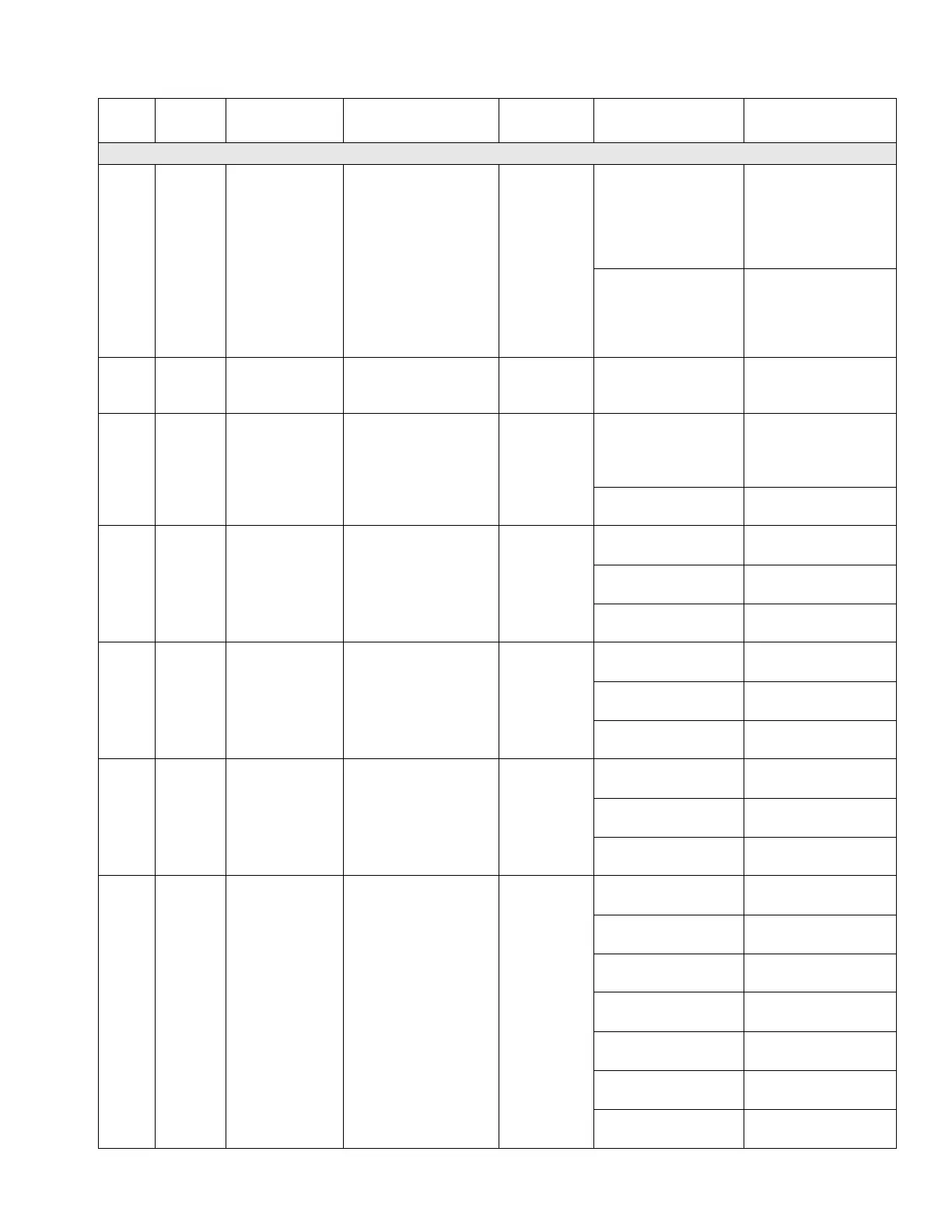

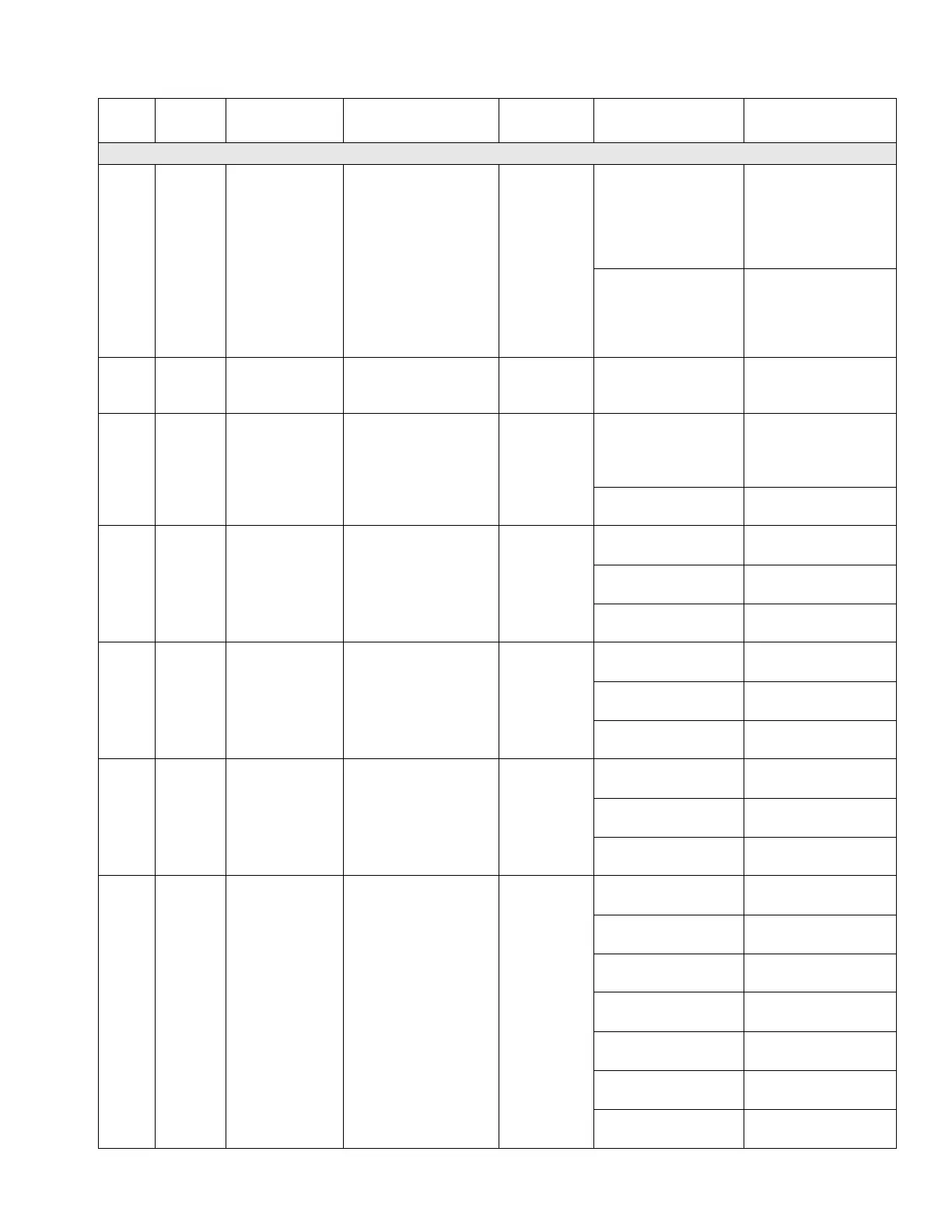

Errors

3A2098S 75

WFD_

WFG_

63 Flow Meter

Required

Operating mode

requires flow meter.

Advisory is issued if

fluid plate settings

require a flow meter but

meter is not present.

Alarm is issued if dis-

pense is attempted in

mode that requires a

flow meter but meter is

not present.

Alarm or

Advisory

(self-clearing)

Selected valve mode

settings require flow

meter

Check valve mode set-

tings

Purchase meter

enabled token for FCM

and install flow meter

FCM key token miss-

ing or invalid

Check for FCM key

token error

EJD_ 64 Job Cycle Time

Out

Job cycle time out Alarm Automation signals did

not properly end job

cycle

Check automation pro-

gramming per job

operating instruction

WXD_ 65 Fluid Plate Error

Detected

Fluid plate error

detected; includes any

error not covered by

another more specific

error

Alarm Analog voltage applied

to pin 1 of the com-

mand cable exceeds

10 Vdc.

Limit signal on pin 1 of

command cable to the

range of 0-10 Vdc.

Failed FCM Replace FCM if neces-

sary

P3F_

P4F_

66 Maximum Inlet

Pressure

Inlet pressure to regula-

tor is above upper limit

set for operation

Alarm or

Deviation

(user select-

able)

Incorrect set limit Verify limit is set cor-

rectly

Material supply pres-

sure is too high

Decrease material sup-

ply pressure

Failed transducer Check transducer;

replace if necessary

P3D_

P4D_

67 Maximum Outlet

Pressure

Outlet pressure of regu-

lator is above upper

limit set for operation

Alarm or

Deviation

(user select-

able)

Incorrect set limit Verify limit is set cor-

rectly

Material supply pres-

sure is too high

Decrease material sup-

ply pressure

Failed transducer Check transducer;

replace if necessary

P1F_

P2F_

68 Minimum Inlet

Pressure

Inlet pressure to regula-

tor is below lower limit

set for operation

Alarm or

Deviation

(user select-

able)

Incorrect set limit Verify limit is set cor-

rectly

Material supply pres-

sure is too low

Increase crease mate-

rial supply pressure

Failed transducer Check transducer;

replace if necessary

P1C_

P2C_

69 Low Pressure Measured outlet pres-

sure less than desired

outlet pressure minus

tolerance

Alarm or

Deviation

(user select-

able)

Incorrect limit set Verify limit is set cor-

rectly

No or insufficient

material flow

Increase material flow

rate

Dispense valve needle

is stuck closed

Dislodge and inspect

needle

Dispense valve leak-

ing

Repair dispense valve

Regulator not operat-

ing correctly

Repair regulator

Pump wink passed

through outlet

Increase pump pres-

sure

Failed transducer Check transducer;

replace if failed

Event

Code

Gateway

Error No. Event Name

Event

Description Event Type Cause Solution

Fluid Plate Events and Errors

Loading...

Loading...