90

If using a 1 1/16-in socket, torque limiting extension, and impact driver 1.

(set CW):

a) Hold impeller by hand. (Use proper PPE.)

b) Using 1 1/16-in socket, torque limiting extension, and impact driver (set CW),

tighten nut.

If using a 1 1/16-in torque wrench and strap wrench: 2.

a) Hold impeller with a strap wrench.

b) Using 1 1/16-in torque wrench, torque (turn CW) nut to 110 ft-lb (149 Nm).

After performing this procedure, install the volute as described in the Volute Installation portion

of paragraph 5.8.4.4, Volute R&R. (See page 74.)

5.8.4.9 AP/CBP/MBP Mechanical Seal R&R

Before the mechanical seal can be replaced, the volute and impeller (including the inducer if ap-

plicable) must be removed from the pump. Refer to paragraph 5.8.4.3 or 5.8.4.4 (page 72 or

page 74) for instructions to R&R the volute and if applicable (pump is an MBP) refer to para-

graph 5.8.4.5 (page 76) for instructions to R&R the inducer and then refer to paragraph 5.8.4.6

(page 81), (AP or MBP) 5.8.4.7 (page 83), or paragraph 5.8.4.8 (CBP on page 87) for instructions

to R&R the impeller.

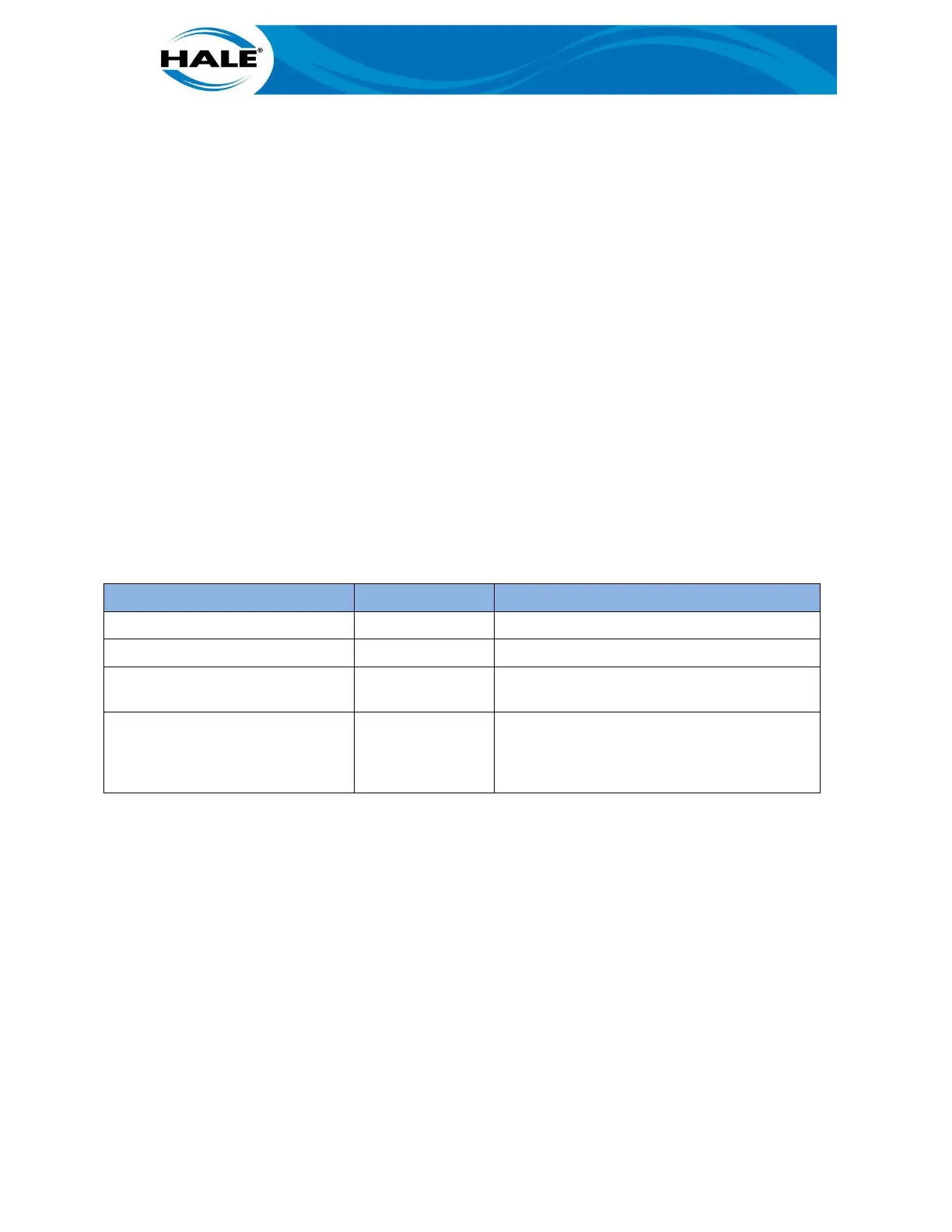

Refer to Table 33 for a list of tools and/or consumables required for this procedure.

Table 33. AP/CBP/MBP Mechanical Seal Bench Procedure Tools And Consumables List

PPE (Eye and Hand Protection) Shop Rag(s) (As Required)

Non-marring Hammer Pac-Ease Lubricant (See paragraph 5.7.3.)

5/32-in (4 mm) Flat Blade

Screwdriver

Alcohol Swabs (See paragraph 5.7.3.)

3/32-in or 7/64-in (2.5 or 3.0 mm)

Hex Key (Allen Wrench)

Mechanical Seal

Installation Tool

<029-0760-00-0>

Mechanical Seal

<See FSG–PL-01483, Sheet 4, Item 5> (AP)

<See FSG–PL-01482, Sheet 4, Item 6> (CBP)

<See FSG–PL-01486, Sheet 4, Item 8> (MBP)

The stationary part of the mechanical seal is located in the center bore of the pump head. The

other part of the seal mounts on the pump shaft and seats against the drive side of the impeller.

See Figure 4 for a diagram of how the seal fits in the pump and Figure 33 for a detailed diagram

of the seal components.

Loading...

Loading...