56

If the gearbox requires internal component replacement or the apparatus configuration does

NOT allow pump access the maintenance method requires both pump and gearbox be removed

as an assembly from the apparatus. (See paragraph 5.8.2.1, AP Removal From The Apparatus.)

When AP gearbox and/or pump maintenance or repairs (which required method two, which sup-

ports gearbox component repairs or pump repairs when pump access is NOT possible) are com-

pleted, the AP pump/gearbox installation back onto the apparatus is accomplished by following

the instructions in paragraph 5.8.8, AP Install On The Apparatus.

Read and understand all the instructions before beginning any pump removal or replacement.

5.8.2.1 General Pump Removal From The Apparatus

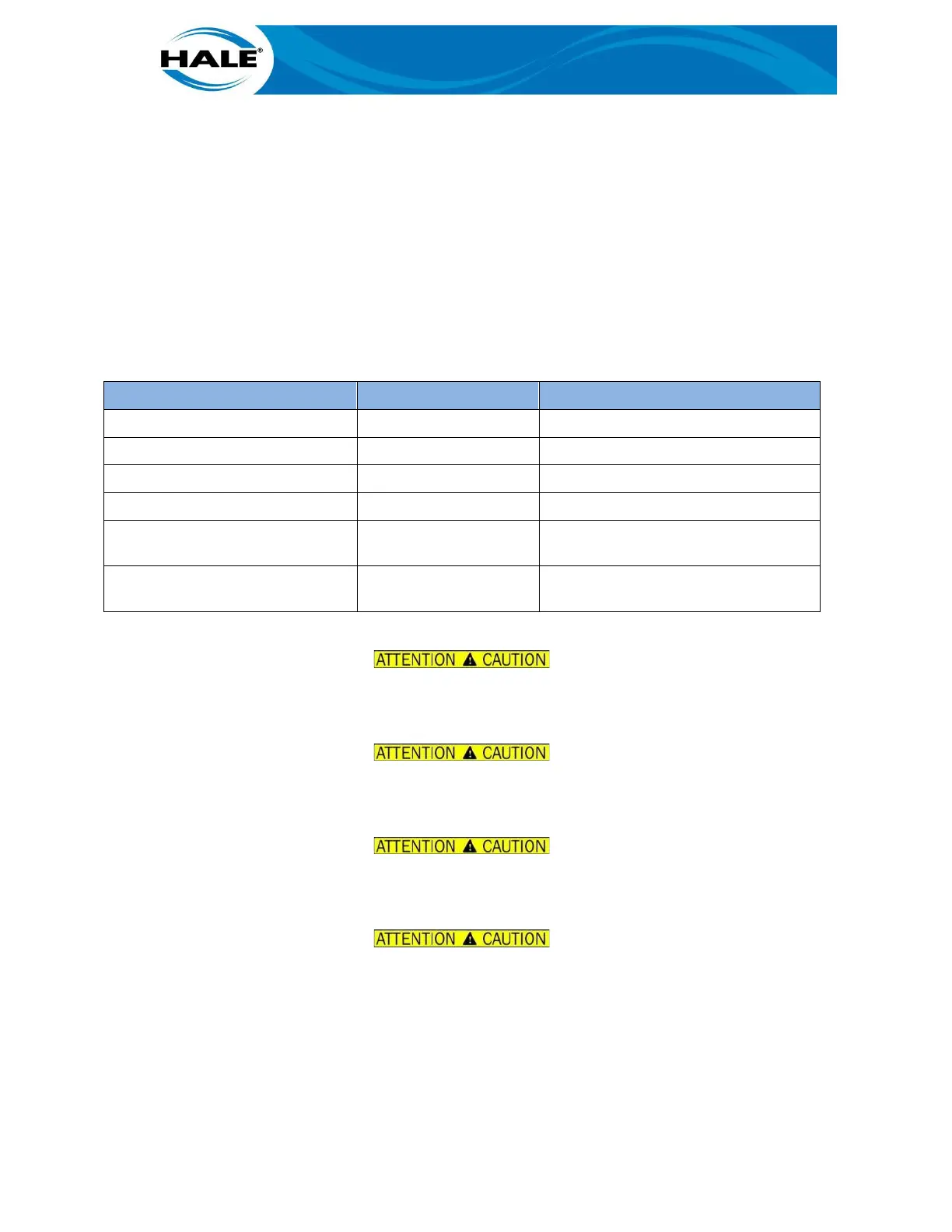

Refer to Table 24 for a list of tools and/or consumables required for this procedure.

Table 24. Pump R&R From The Apparatus Tools And Consumables List

PPE (Eye and Hand Protection) None

Shop Rag(s) (As Required)

PPE (For Handling Oil) Tags (Wire, Etc.)

Catch Pan (For Gear Oil)

Wheel Chocks

Lifting Device And Rigging

(Or Jack)

9/16-in Socket (8 Pt.) And Ratchet

(Or Wrench Or Adjustable Wrench)

** None for pump – see OEM/Apparatus documentation for a complete list.

THE AP PUMP AND GEARBOX ASSEMBLIES WEIGH APPROXIMATELY 140 LBS

(64 KG). USE PROPER LIFTING DEVICE WHEN REMOVING OR INSTALLING THE PUMP

AND GEARBOX ASSEMBLY.

THE CBP PUMP AND GEARBOX ASSEMBLIES WEIGH APPROXIMATELY 100 LBS

(45 KG). USE PROPER LIFTING DEVICE WHEN REMOVING OR INSTALLING THE PUMP

AND GEARBOX ASSEMBLY.

THE MBP PUMP AND GEARBOX ASSEMBLIES WEIGH APPROXIMATELY 170 LBS

(77 KG). USE PROPER LIFTING DEVICE WHEN REMOVING OR INSTALLING THE PUMP

AND GEARBOX ASSEMBLY.

THE RSD PUMP AND GEARBOX ASSEMBLIES WEIGH APPROXIMATELY 225 LBS

(102 KG). USE PROPER LIFTING DEVICE WHEN REMOVING OR INSTALLING THE

PUMP AND GEARBOX ASSEMBLY.

A. Prepare apparatus/vehicle for pump removal.

Place apparatus out of service in accordance with departmental proce-1.

dures.

Park vehicle on level surface. 2.

Loading...

Loading...