44

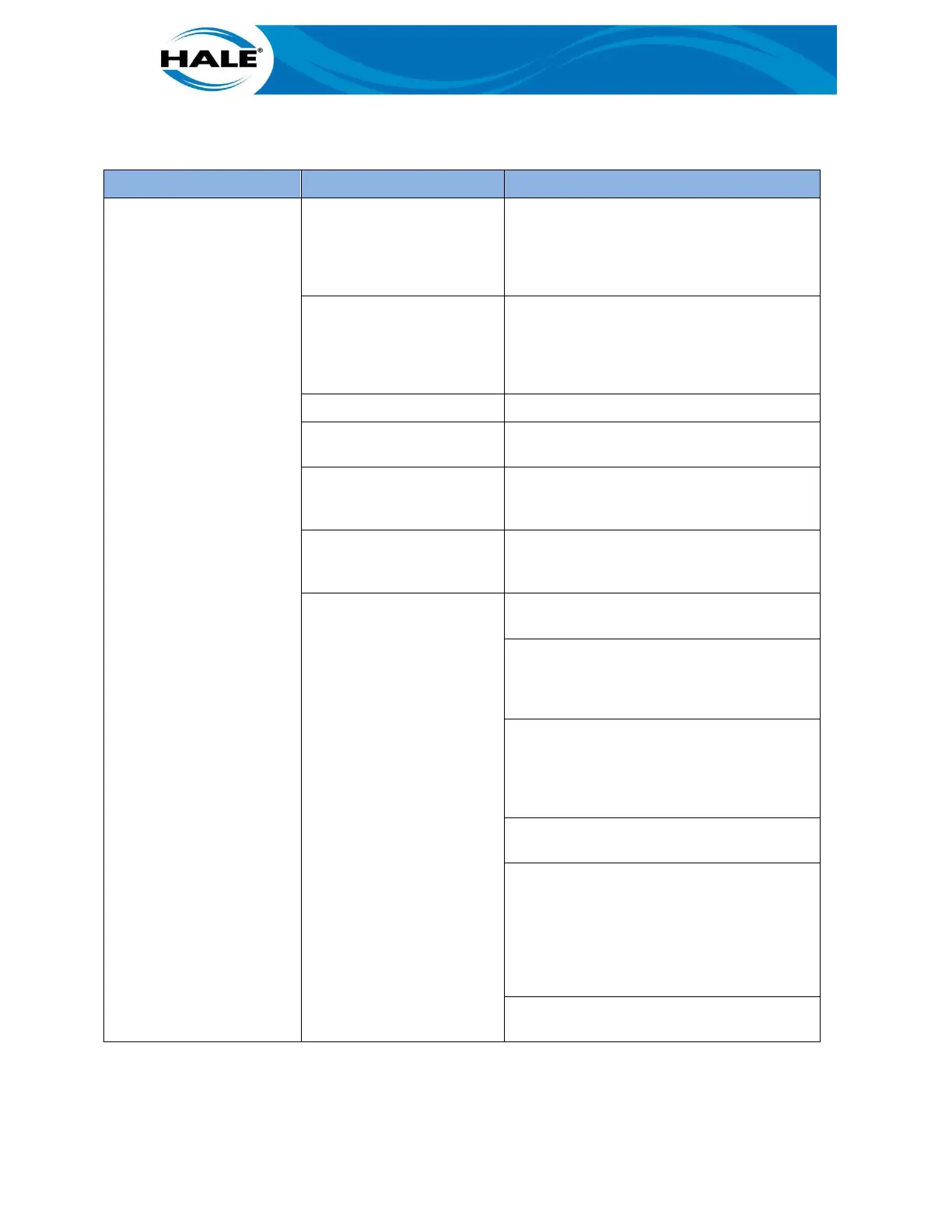

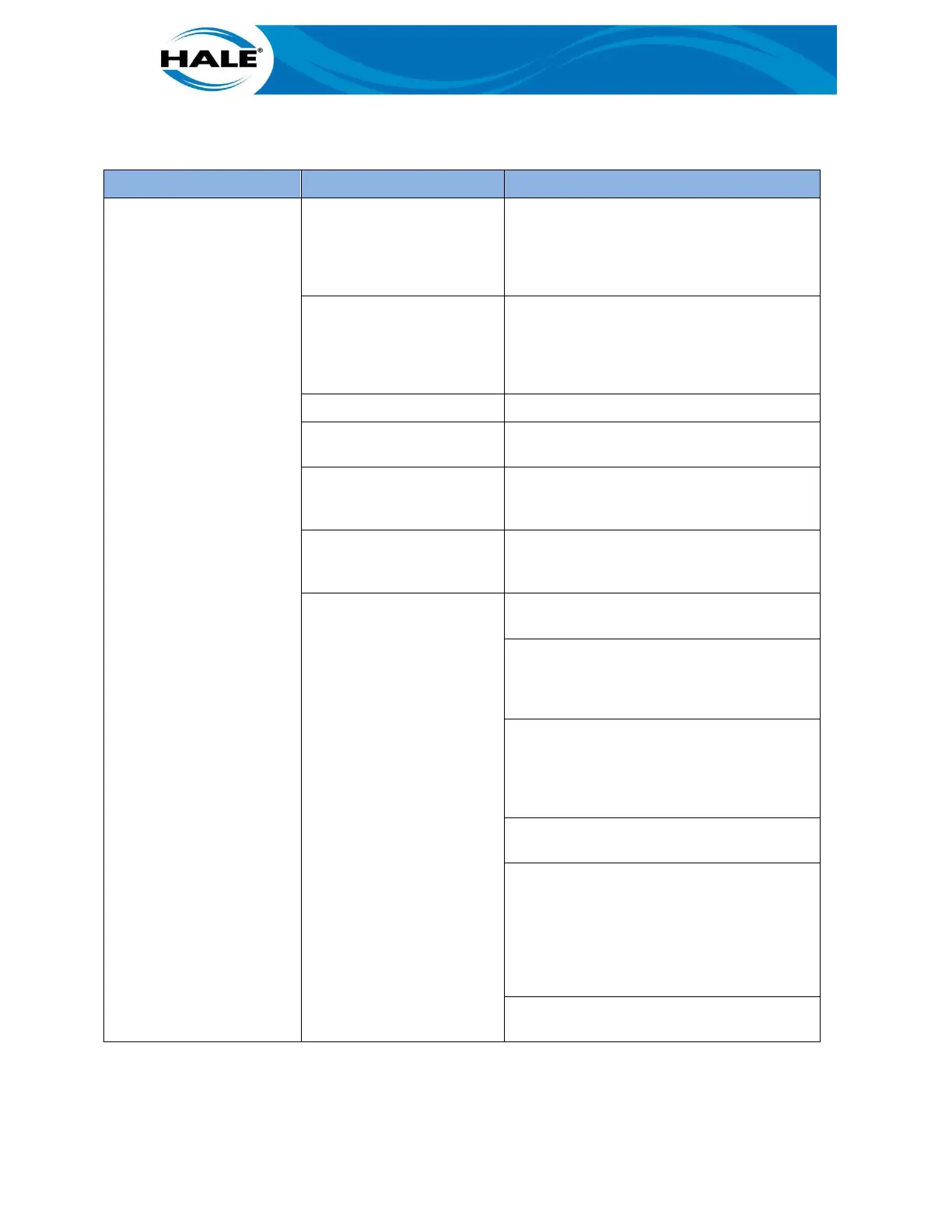

5.1.2 Pump Priming Problems

Table 12. Pump Priming SCR Table

Pump Loses Prime

Or Will NOT Prime

Electric Priming System No recommended engine speed is required

to operate the electric primer. However, an

engine RPM of 1,000 will maintain the elec-

trical system while providing enough speed

for initial pumping operation.

Defective Priming System Check the priming system by performing a

“Dry Vacuum Test” per NFPA standards. If the

pump holds vacuum, but primer pulls less

than 22 (± 2) inHg of vacuum, it could indi-

cate excessive wear in the primer.

Suction Lift Too High Do NOT attempt lifts exceeding 22 ft.

Restricted Suction Strainer Remove obstruction from suction hose

strainer.

Suction Connections Loose

Or Dirty

Clean and tighten all suction connections.

Check suction hose and hose gaskets for

possible defects.

Primer NOT Operated Long

Enough

Proper priming procedures should be fol-

lowed. Do not release the primer control be-

fore assuring a complete prime.

Air Leaks Attempt to locate and correct air leaks using

the following procedure.

1. Perform dry Vacuum Test on pump per

NFPA standards with 22 (± 2) inches mini-

mum vacuum required with loss not to ex-

ceed 10 inches of vacuum in 5 minutes.

2. If a minimum of 22 (± 2) inches of vacuum

cannot be achieved, the priming device or

system may be defective, or the leak is too

big for the primer to overcome (such as an

open valve).

3. After priming, shut off the engine. Audible

detection of a leak is often possible.

4. Connect the suction hose from the hydrant

or the discharge of another pumper to pres-

surize the pump with water, and look for visi-

ble leakage and correct. A pressure of 100

psi (6.9 bar) should be sufficient. Do not ex-

ceed pressure limitations of pump, accesso-

ries, or piping connections.

5. The suction side relief valve can leak. Plug

the valve outlet connection and retest.

Loading...

Loading...