31

4. PREVENTIVE MAINTENANCE

Regular preventive maintenance assures continued dependable operation. This section provides

recommended actions to be completed for both the booster pump and the ancillary equipment.

The pump preventive maintenance actions listed are scheduled to be completed after each use

and on a weekly, quarterly and annually basis.

4.1. Preventive Maintenance Plan And Schedule

Hale Products recommends the preventive maintenance and inspections listed in Table 7 be per-

formed as scheduled. The booster pump requires very little care and maintenance, however, the

preventive maintenance and inspections required are important. The booster pumps do NOT re-

quire any daily, weekly, or monthly preventive maintenance. The listed preventive maintenance,

inspections and checks are required to ensure proper and economical operation and to minimize

corrective maintenance. Table 7 lists the projected preventive maintenance on a per use, quar-

terly, annual, and triennium basis.

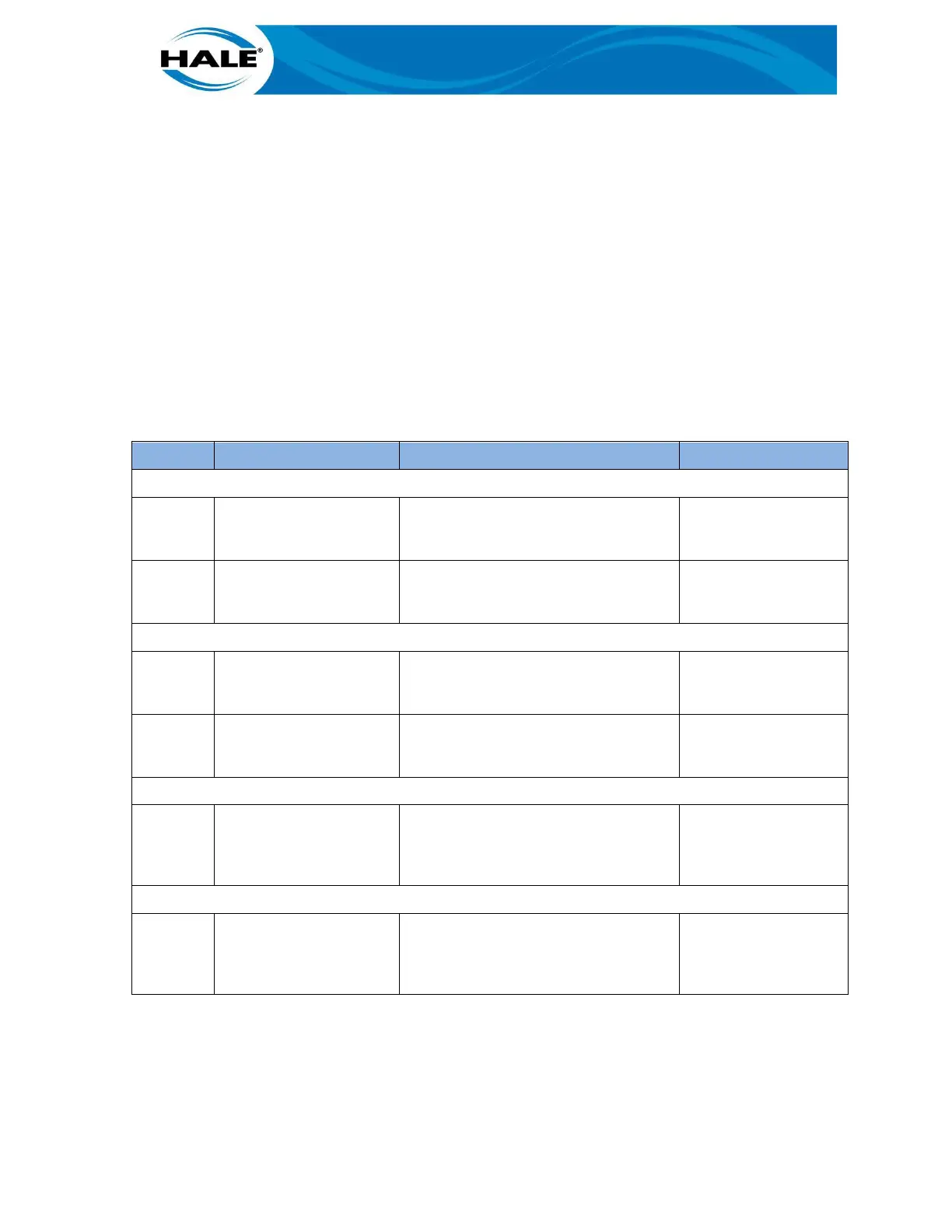

Table 7. Recommended Preventive Maintenance – Pump

Flush if Contaminated Flush pump thoroughly with clean water

(See paragraph 4.4.1, Flush After Each

Use)

Supply of clean water

Leakage Checks Check for water or oil leaks (wipe off

road dirt and debris) (See paragraph

4.4.2, Leakage Checks)

Shop Rags

Quarterly (Every 3 Months)

Oil Level Check Check gearbox oil level using sight glass

(See paragraph 4.4.3.1, Check Gearbox

Oil Level)

None

Perform Vacuum Check Use installed primer to pull vacuum on

pump and valves (See 4.4.3.2, Perform

Vacuum Test)

None

Annually (Every 12 Months)

Perform NFPA 1911 Per-

formance Level Test

Check the pump (according to the rating

in Table 9 at each capacity and com-

pare the results to when the pump was

first placed in service.

Supply of clean water

Triennium (Every 36 Months)

Oil Change Drain oil from gearbox and refill with

new oil

(See paragraph 4.4.6.1, Gearbox Fluid

Change)

1.25 qt Full Synthetic

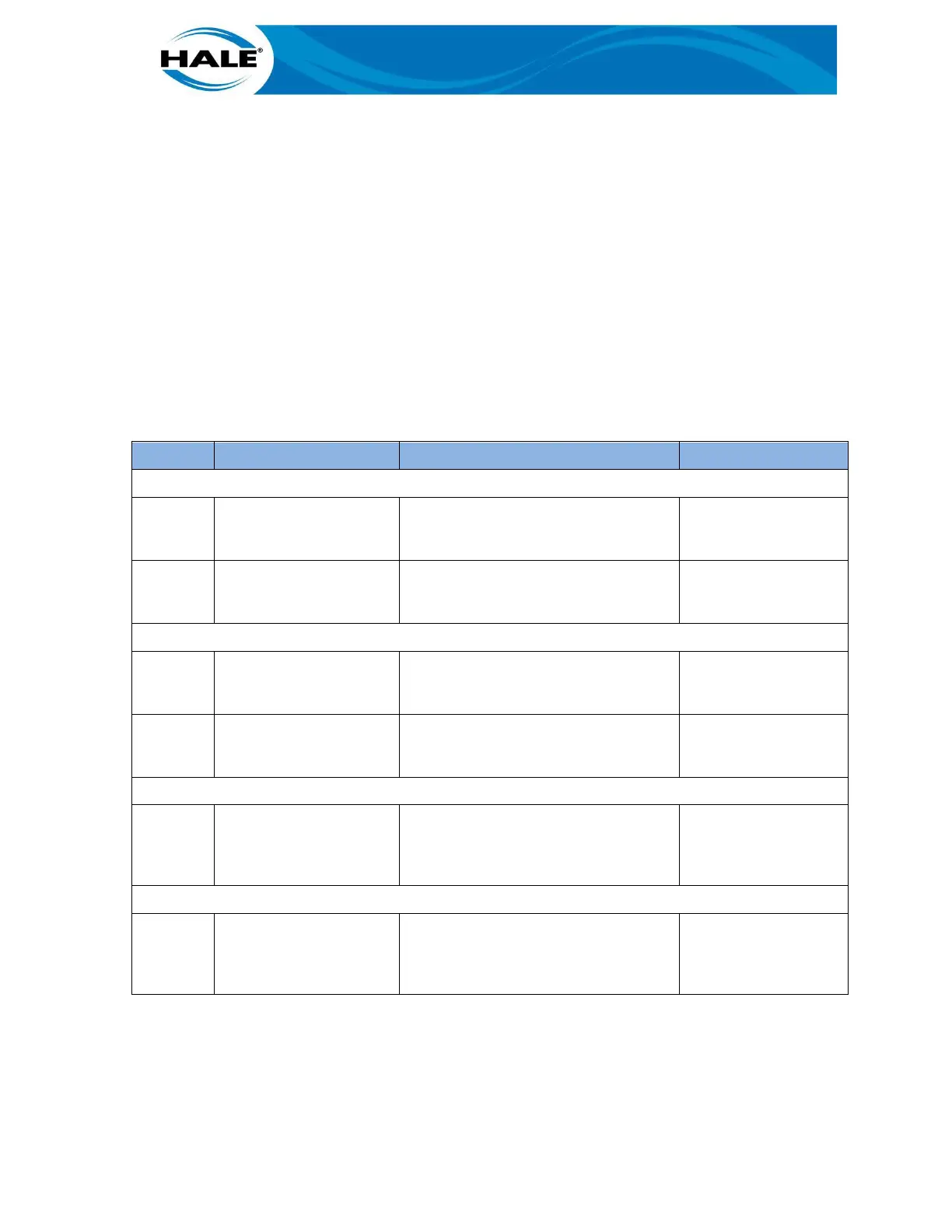

Additionally, Hale Products recommends the preventive maintenance and inspections listed in

Table 8 also be performed as scheduled. Hale and OEM ancillary equipment preventive mainte-

nance tasks take little time to accomplish and consist of leak testing, operational checks, lubri-

cation and cleaning. The listed preventive maintenance, inspections and operational checks are

required to ensure proper and economical operation and to minimize corrective maintenance.

Loading...

Loading...