70

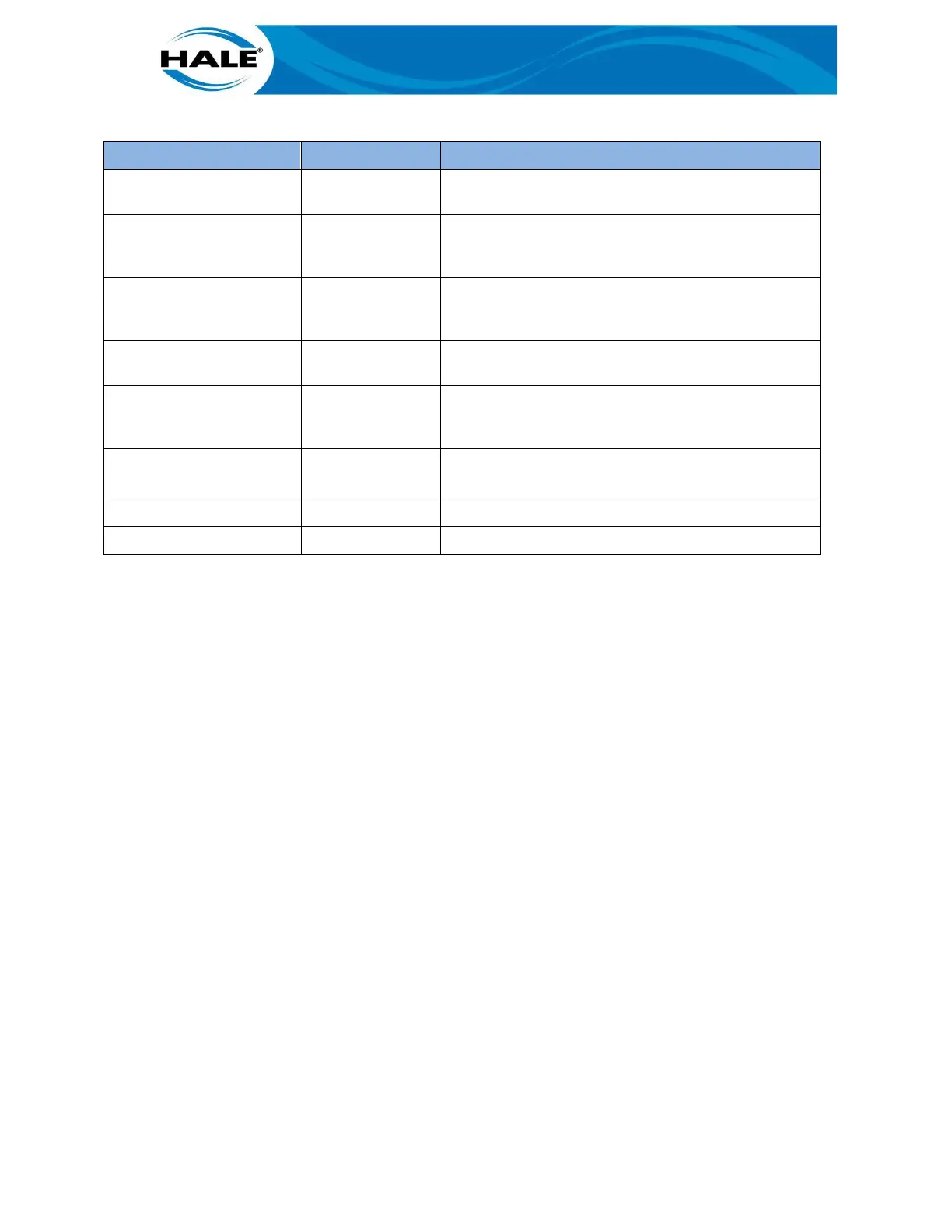

Table 26. RSD Volute R&R Tools And Consumables List

PPE

(Eye and Hand Protection)

None Shop Rag(s) (As Required)

5/8-in Wrench

(Or Ratchet Wrench)

(Or Pass Thru Ratchet)

O-ring Lubricant (See Table 20.)

Hooked-end Dental Pick (or

Hose Removal Tool)

O-RING <See FSG–PL-01487, Sheet 4, Item 30> (Two

Required)

(Suction Head To Volute) (Volute To Pump Head)

Adjustable Wrench (For

cooling tubing removal)

Grease (See paragraph 5.7.2, Recommended Lubri-

cants.)

Gasket Scrapper Gasket <See FSG–PL-01487, Sheet 4, Item 3> (Two

Required)

(Suction Head To Volute) (Volute To Pump Head)

Non-marring Hammer Volute: (ONLY ONE REQUIRED – SELECT FROM: )

<See FSG–PL-01487, Sheet 4, Item 29>

Loctite™ Clean-Up Solvent

Loctite™ 243 (Or Equivalent)

Perform the following to remove and replace the volute.

NOTES

Remove any suction tube and/or piping blocking access to the pump per

OEM/equipment manufacturer instructions.

Remove any discharge piping blocking access to the pump per OEM/equipment

manufacturer instructions.

RSD Volute Removal

A. If pump is still in apparatus, match mark/note/tag and then disconnect suc-

tion, discharge, and cooling lines.

B. If pump is still in apparatus, tag and disconnect any electrical wiring.

C. Match mark volute and pump head to ensure proper alignment during reas-

sembly.

D. If pump is still in apparatus, disconnect ONLY mounting bracket(s) required

for volute removal.

E. Using 5/8-in ratchet wrench (or pass thru ratchet set CCW), remove

twelve (12) 7/16 — 14 X 1.25–in screws that hold volute to pump head.

NOTE

Do NOT damage brass clearance rings, inducer, or impeller during volute removal.

Loading...

Loading...