110

b) Apply Loctite™ 580 (or equivalent) to threads of each screw.

c) Hand start 16 M8 x 1.25 x 20 mm long screws (each with one (1) washer).

d) Using 13 mm wrench (or socket with driver), tighten cover screws.

e) Using a circular pattern, tighten screws evenly and torque IAW Table 22.

(Do NOT over tighten.)

C. Perform Gearbox Fluid Change (see paragraph 4.4.6.1 on page 42.)

5.8.7.2 Pump Clearance Ring R&R

When new, the radial clearance between the impeller hub and the clearance ring is between

0.006 and 0.0085 inch. Any increase will allow more bypass and result in lower performance. It

should not be necessary to replace clearance rings and impeller until the average radial clear-

ance exceeds 0.012 to 0.017 inch, as measured with calipers. Refer to Table 23.

This procedure does NOT provide access instructions, ONLY steps to R&R the clearance rings are

provided herein.

The Flex series pumps utilize two styles of clearance rings, For an AP/CBP/MBP a typical brass

ring style is located in the volute while for a RSD this style ring in located in the suction head. All

pumps utilize a wraparound style ring located in the pump head.

If pump is an AP, CBP, or MBP; refer to paragraph 5.8.4.3 (see page 72) or paragraph 5.8.4.4

(see page 74) for volute removal. If the pump is a RSD refer to paragraph 5.8.4.1 (see page 67)

for suction head removal. Then for pump head removal instructions refer to paragraph 5.8.4.11

(see page 96) or paragraph 5.8.4.12 (see page 98).

Refer to Table 40 for a list of tools and/or consumables required for this procedure.

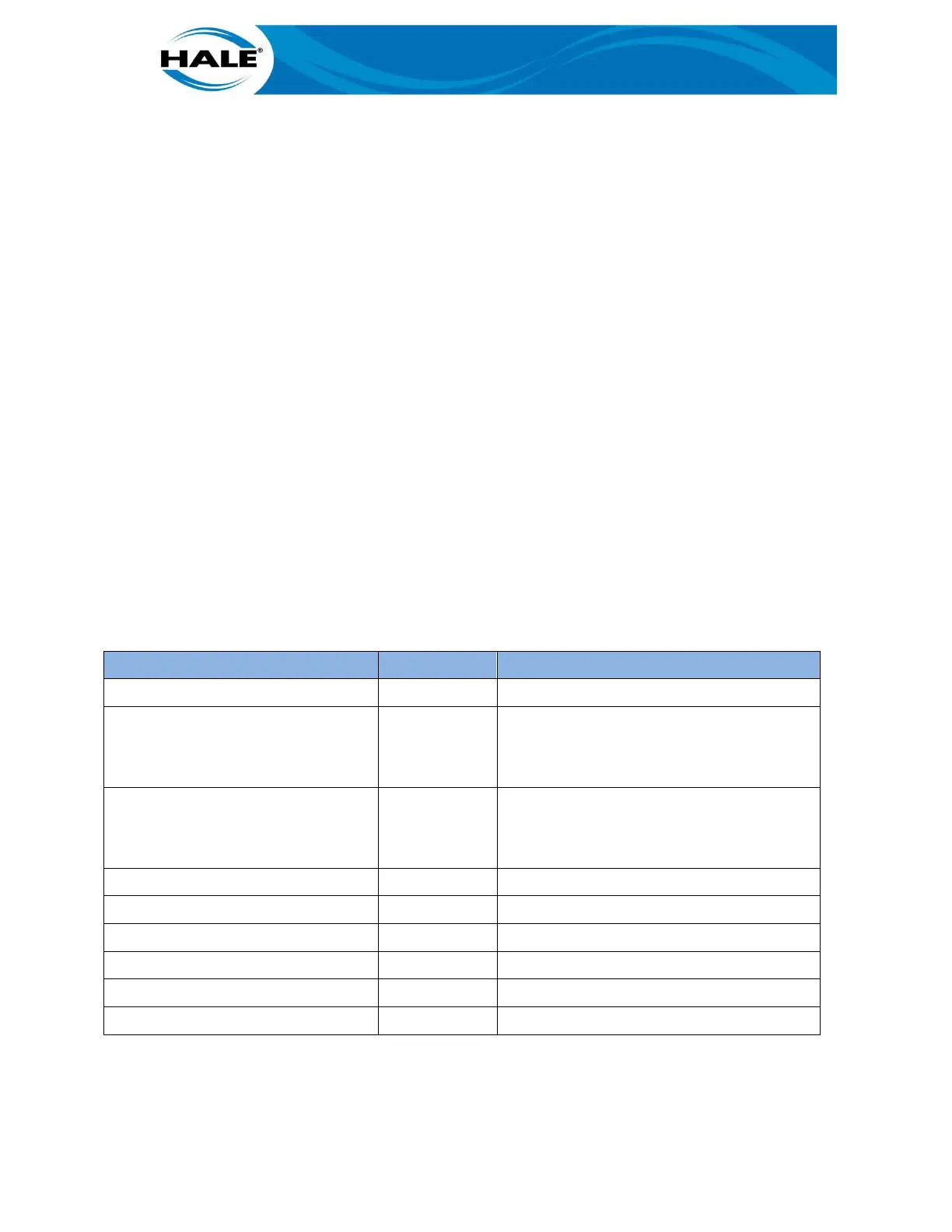

Table 40. Pump Clearance Ring R&R Tools And Consumables List

PPE (Eye and Hand Protection) None Shop Rag(s) (As Required)

Cutting Wheel

(Electric or Pneumatic)

Clearance Ring (Volute Side)

<See FSG–PL–01483 Sheet 4 Item 2> (AP)

<See FSG–PL–01482 Sheet 4 Item 2> (CBP)

<See FSG–PL–01486 Sheet 4 Item 3> (MBP)

L-shaped Pry Bar

(12-in Recommended)

(Three [3] Required)

Clearance Ring (Pump Head Side)

<See FSG–PL–01483 Sheet 4 Item 8> (AP)

<See FSG–PL–01482 Sheet 4 Item 8>(CBP)

<See FSG–PL–01486 Sheet 4 Item 11>(MBP)

Hammers (Non-marring and shop) Loctite 680 (Or Equivalent)

Hydraulic Press

Loctite Clean-Up Solvent (Or Equivalent)

Cold Cut Chisel Wire Brush

1/ 4-in Drill Bit

Drill

Mechanics Vise (14-in Recommended)

** A non-marring hammer may be used being careful NOT to bend, warp, or chip the

clearance ring.

Loading...

Loading...