20

Subject to change without notice

If the heater seems to be defective, remove the CRT socket and

measure the CRT heater resistance between pin 1 and 14 to

eliminate the CRT socket.

1.9 Measures

If one of these voltages is missing or strongly deviating the

following procedure is recommended:

– Disconnect the instrument from mains/line.

– Remove the interface mounting plate.

– Remove the power supply shielding.

– Unsolder the wire soldered to the protective earth (PE)

connection at the inner side of the rear chassis, marked

by an earth symbol.

– Remove all cables and wires connected to the power sup-

ply.

– Unfasten the power supply mounting nuts.

– Remove the power supply and replace it by a new power

supply.

Proceed in reverse order to mount the new power supply.

Attention!

Special care must be taken for the protective earth connection

(PE). It must be fi xed and thereafter soldered in such a way

that even accidental contact with a soldering iron doesn`t

open the connection.

Security check!

Check that after PS board replacement the protective earth

connection is reestablished.

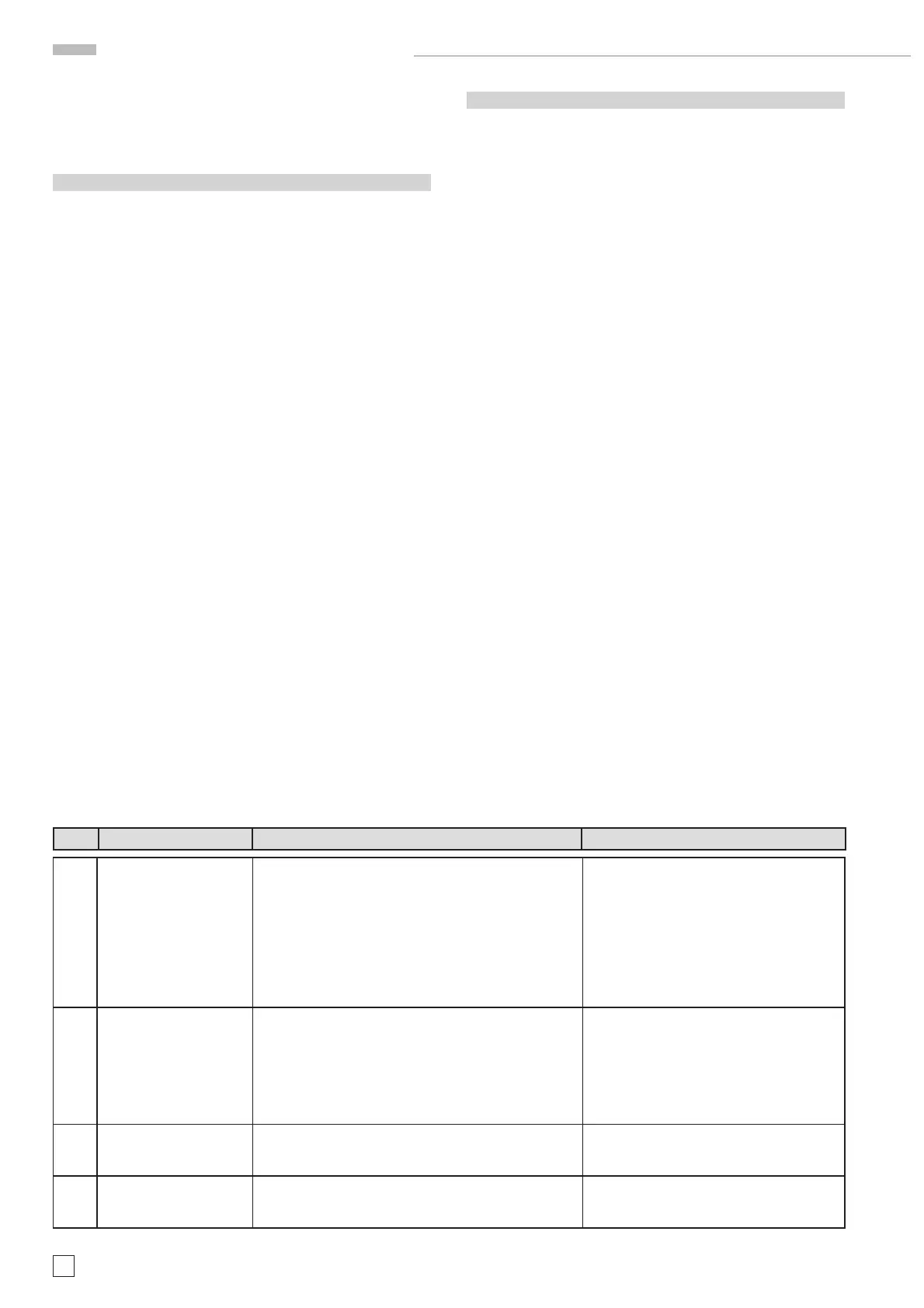

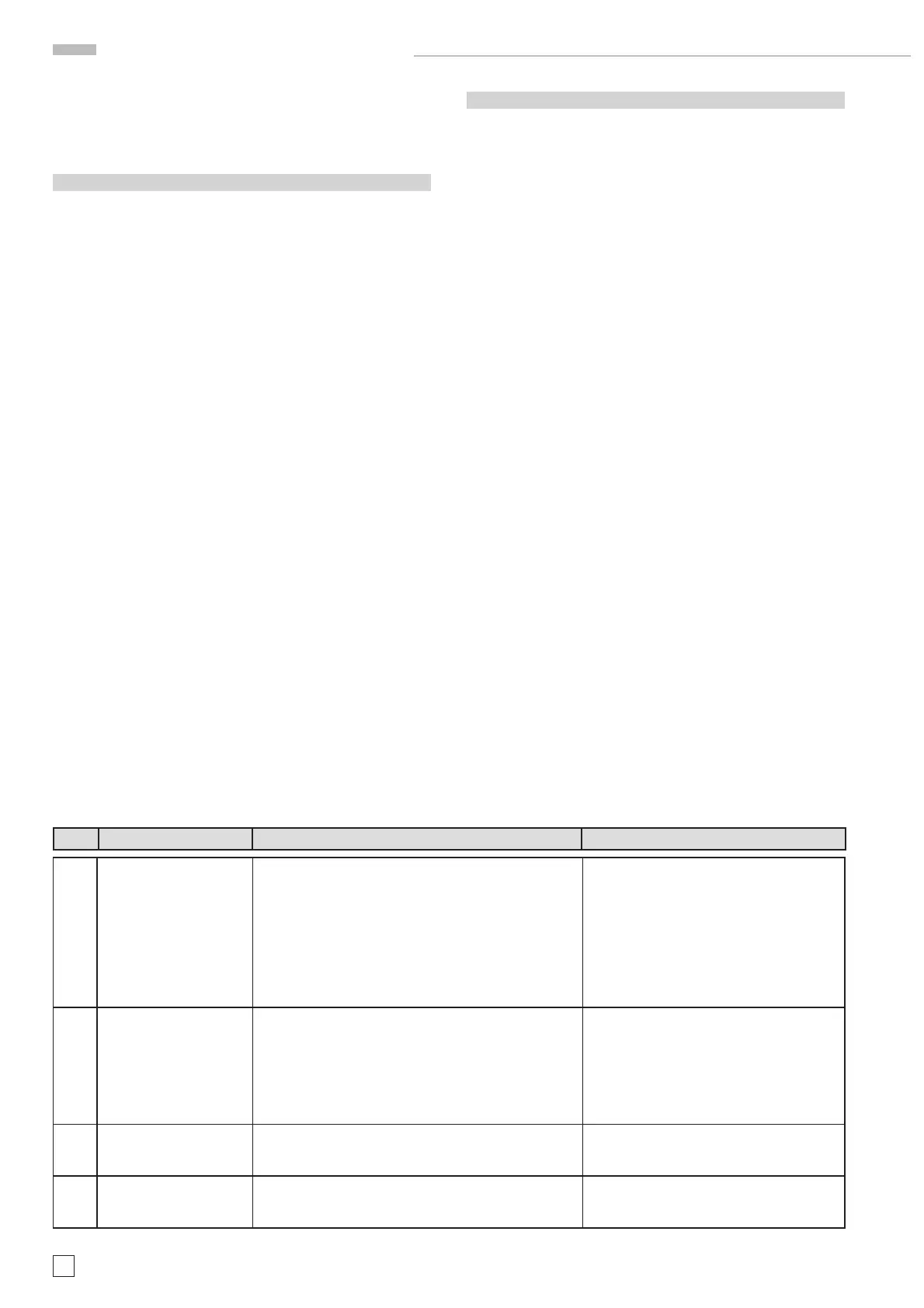

Item Instrument Behavior What to do Remark

2.1 No front panel LED lit,

no trace and no readout

visible on the screen.

Pull out fuse holder and check the (external accessible)

fuse. If the fuse is blown, replace it and switch the ins-

trument on again.

If the error is still present, and the (external accessible)

fuse is blown again, continue with item 2.3.

If the (external accessible) fuse is not blown, continue

with item 2.2.

The instrument must be disconnected from

mains/line before checking the fuse.

2.2 Remove the power supply shielding as described under

item 1.9 and check the (internal accessible) fuse on the

PS board. If the fuse is blown, replace it and switch the

instrument on again.

If the error is still present, and the (internal accessible)

fuse is blown again, continue with item 2.3.

The instrument must be disconnected from

mains/line before checking the fuse.

2.3 Replace the power supply by a new one as described

under item B1.9 and adjust the new power supply (item

1.10).

2.4 Security check!

Check that after PS board replacement the protective

earth connection is re established.

1.10 Adjustment after power supply change.

The following procedures are required after changing a power

supply due to tolerances.

– Check and adjust +65 V and +12V as described under item

1 and 2 in the Adjustment Procedure.

– Press SETTINGS pushbutton, select “Self Cal” and “Start”

the self calibration.

– Check time base and Y accuracy and make corrections if

required (Adjustment Procedure item 25, 59 and 60).

C: Error Diagnostics

The following examples will help you to determine the board to

be replaced or repaired. Due to each board’s comprehensive

functions it is not always possible to determine one board

precisely. Thus it might be necessary to change more than

one board.

As explained before under item B 1, the power supply check

has the highest priority.

The MC board has the second highest priority, as it controls

most of the other boards with the exception of the power supply

board. Thus if the power supply is ok, but no trace becomes

visible and/or the instrument does not respond to the controls

it is recommended to change the MC board fi rst.

If the MC board was the reason for an error and is replaced,

don`t forget to make a new adjustment of item 62 as described

in the Adjustment Procedure.

Attention!

It is recommended to reinstall the old board if a new board

did not solve the problem.

HM1508-2 Troubleshooting

Loading...

Loading...