6 - Maintenance

172

μ

ATTENTION! Before tightening the 4 bolts for the head (2), the

diaphragm must be positioned between centre and top to

ensure correct sealing between diaphragm pump housing and

diaphragm cover. Turn the crank shaft if necessary.

Lubrication After Assembly

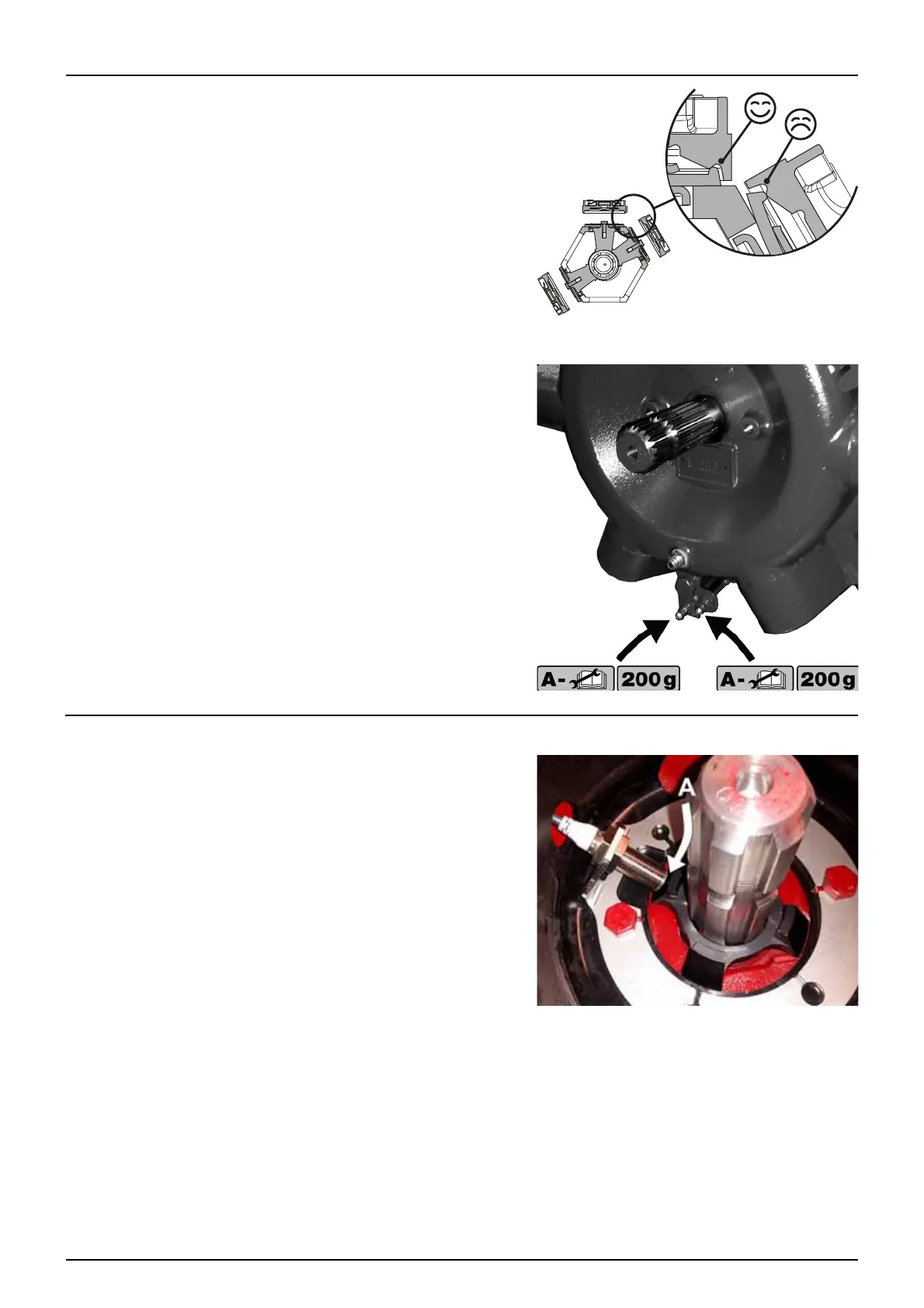

After disassembling the pump (diaphragm renewal, etc.), the pump

MUST be lubricated with 200 g grease into each lubrication point.

HARDI pump grease cartridge (400g): HARDI item no. 28164600

Overhaul Kit

Pump model: 464.

Diaphragm pump overhaul kit (valves, seals, diaphragms etc.) can be

ordered. Detect the pump model - the overhaul kit can be ordered by

your local dealer.

Model 464: HARDI item no. 75586000.

Speed Transducer for Pump

The speed transducer, measuring rounds per minute (rpm), is located at

the inner side of the PTO shield. This sensor is an inductive type, which

requires metallic protrusions to pass by it to trigger a signal.

If the sensor is exchanged, it must installed accurately to function.

Adjustment

1. Adjust the air gap (A) between sensor tip and pump part is set by

turning the nuts on the support bracket for the sensor.

The air gap (A) must be set to 1 mm (+0.3/-0.0 mm).

Use a feeler gauge or similar tool to verify.

2. Verify transducer function on the controller:

• HC 6500 / ISOBUS VT:

Monitor the menu [4.5.4.9.6 PTO pump frequency].

Loading...

Loading...