8 - Technical specifications

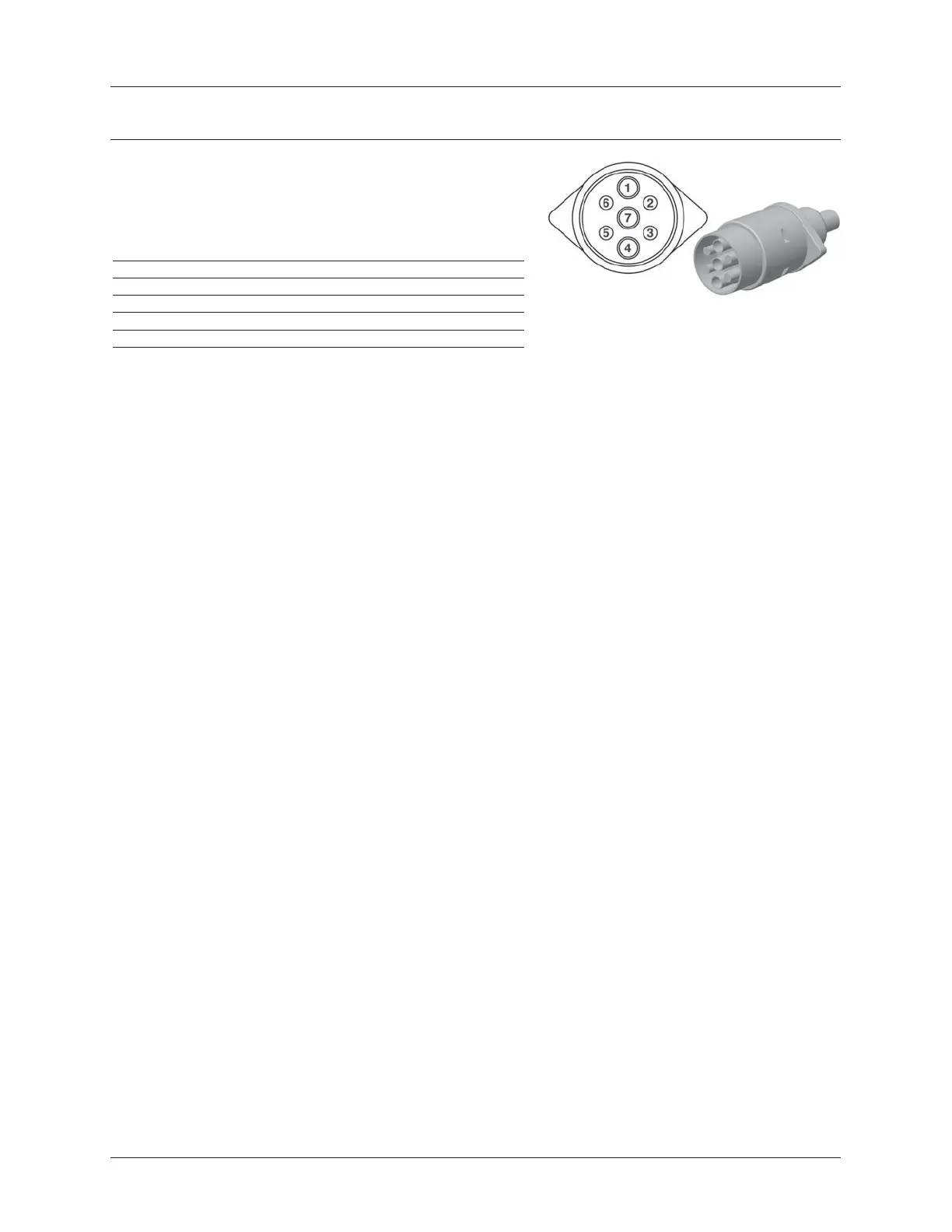

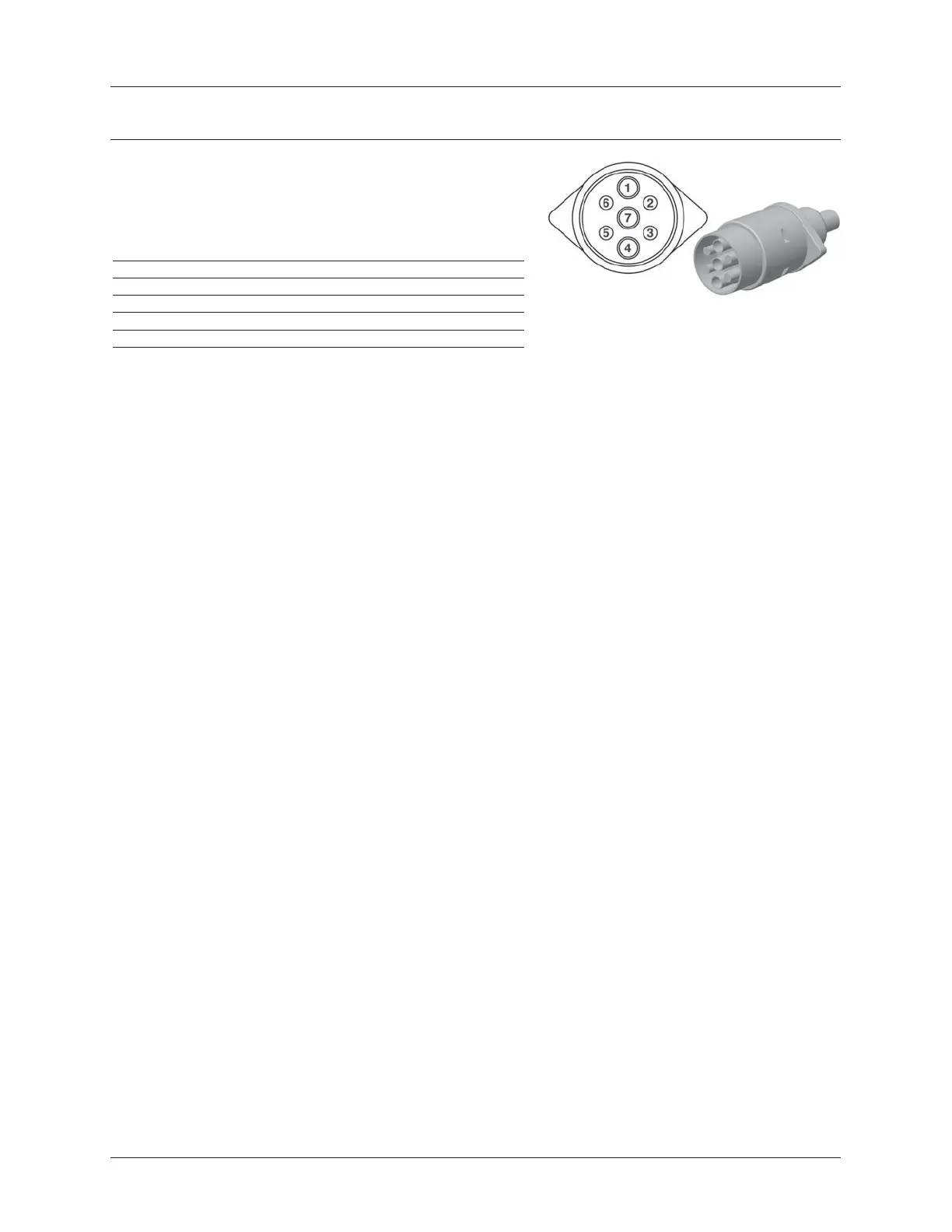

8.4

Position Wire color

1. LH direction indicator Yellow

2. Free Blue

3. Frame White

4. RH direction indicator Green

5. RH rear position lamp Brown

6. Stop lamps Red

7. LH rear position lamp Black

The wiring is in accordance with ISO 1724.

Rear lights

Electrical connections

Loading...

Loading...