38

PME-MP85

A0897−3.4 enHBM

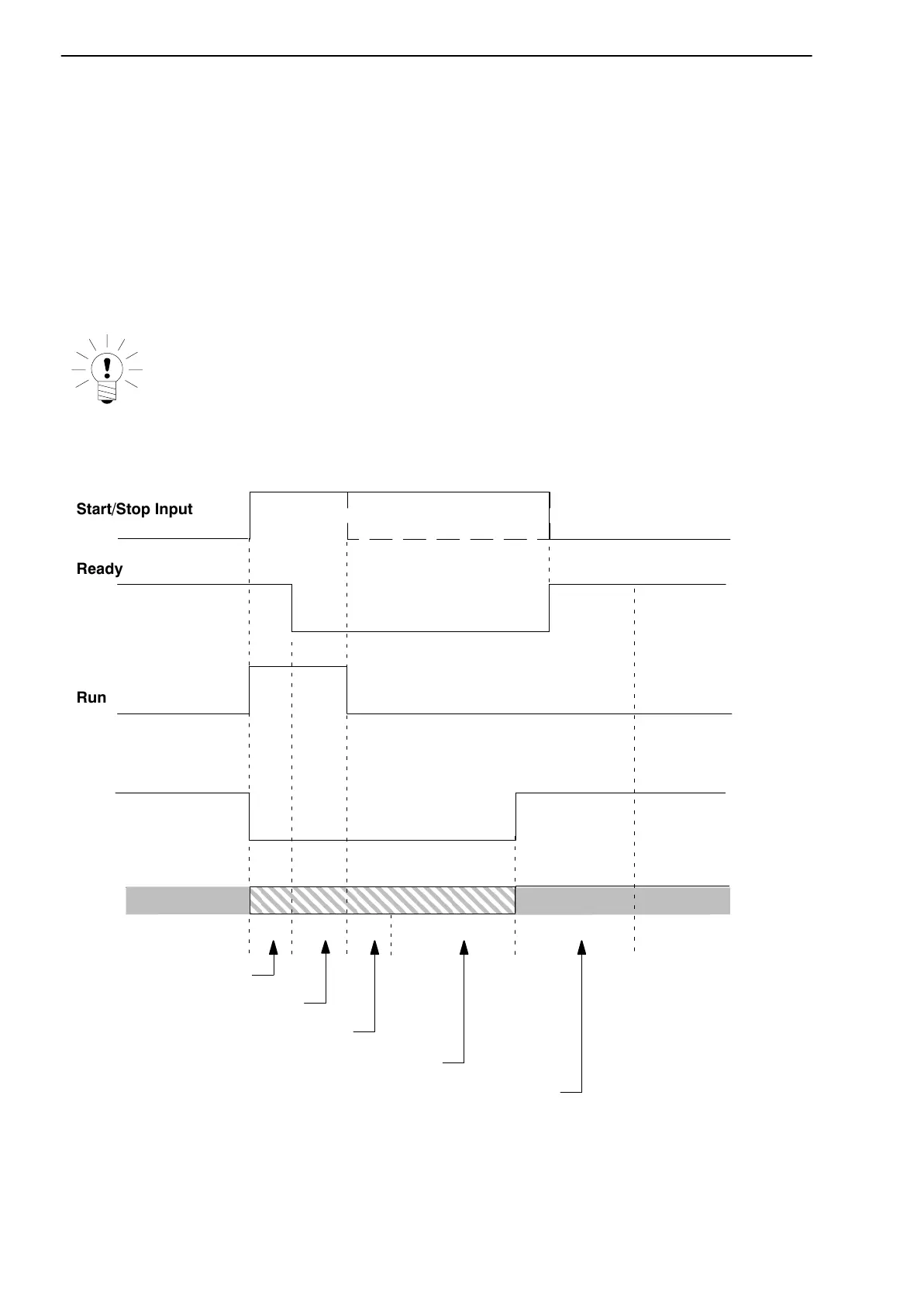

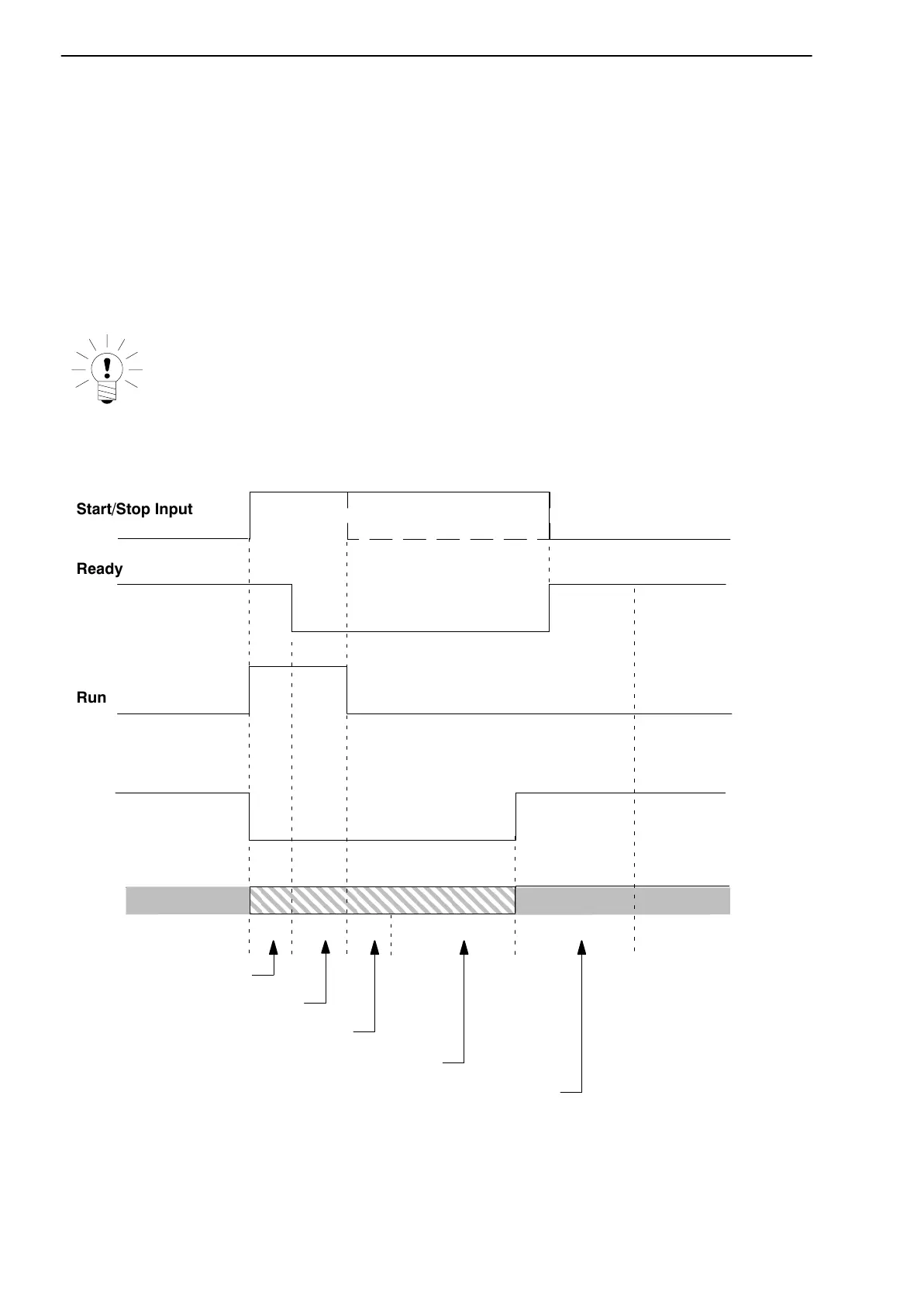

b.) Process optimized storage of curves and results

The below diagrams apply, if you choose the “Process optimized storage” sto-

rage method and want to save curves and/or results on the MMC or externally

via CAN. In contrast to the “Storing without data loss” method, the READY si-

gnal can be reset to 1 even if the device is not yet ready to save new data.

Consequently the results and curve files might not be transmittes if you start a

new measurement immediately. This method should only be chosen if extre-

mely fast processes must be monitored and the results and curves are merely

used for random sample checks.

NOTE

Before starting a new measurement, the READY bit must have been re-

set to 1.

Start/Stop Input

Ready

Running

Result valid

Process in order

External stop

External stop or end condition occurred

The READY signal is

not reset to 1 until

there has been an

external stop.

Once the evaluation time

has expired, you can

read off result 0 or 1 at

the output.

Only if “Result valid” = 1,

the process result (Pro-

cess in order) is valid.

Initialisization typ. 25 ms

Data acquisition running

Time until stop

Offline evaluation

Data storage

State undefined

Loading...

Loading...