059327–00 REV. C

HEAT-TIMER CORP.

|

41

SYSTEM

A

B

C

D

Full Modulation Sequencing Control

1

2

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

CUR / VLT

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

Mini-MOD

-------- SETTINGS ----

Season Winter

Set Point 70

o

F

<System Settings>

<Maintenance>

<History>

<System Startup>

BACK SELECT

--- SENSOR TYPE ---

Set Point

o

F

Set Point

o

C

Reset

o

F

Reset

o

C

BACK ▲▼ SAVE

- EMS INPUT MODE -

Disable

Enable

BACK ▲▼ SAVE

-EMS 4ma SETPOINT -

120

o

F

[ ]

BACK ▲▼ SAVE

-EMS 20ma SETPOINT-

220

o

F

[ ]

BACK ▲▼ SAVE

-- OUTPUT A TYPE --

4-20ma

0-10v

0-5v

2-10v

1-5v

BACK ▲▼ SAV

E

STAGE A SETTINGS

Mode Auto

<Prev Stage>

<Next Stage>

BACK ▲▼ SAVE

SYSTEM

A

B

C

D

Full Modulation Sequencing Control

1

2

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

Mini-MOD

STAGE A MODE

Auto

Standby

Manual

Off

On

BACK ▲▼ SAVE

STAGE A SETTINGS

Mode Auto

Ignition % 1%

Mod Start % 80%

<Prev Stage>

<Next Stage>

Copy Settings

BACK ▲ ▼ SAVE

SYSTEM

A

B

C

D

Full Modulation Sequencing Control

1

2

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

Mini-MOD

STAGE A MODE

Auto

Standby

Manual

Off

On

BACK ▲▼ SAVE

STAGE A SETTINGS

Mode Auto

Ignition % 1%

Mod Start % 80%

<Prev Stage>

<Next Stage>

Copy Settings

BACK ▲ ▼ SAVE

STAGE A SETTINGS

Mode Auto

<Prev Stage>

<Next Stage>

BACK ▲▼ SAVE

SYSTEM

A

B

C

D

Full Modulation Sequencing Control

1

2

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

Mini-MOD

06 ETS-LT CONTROL MODULE WIRING

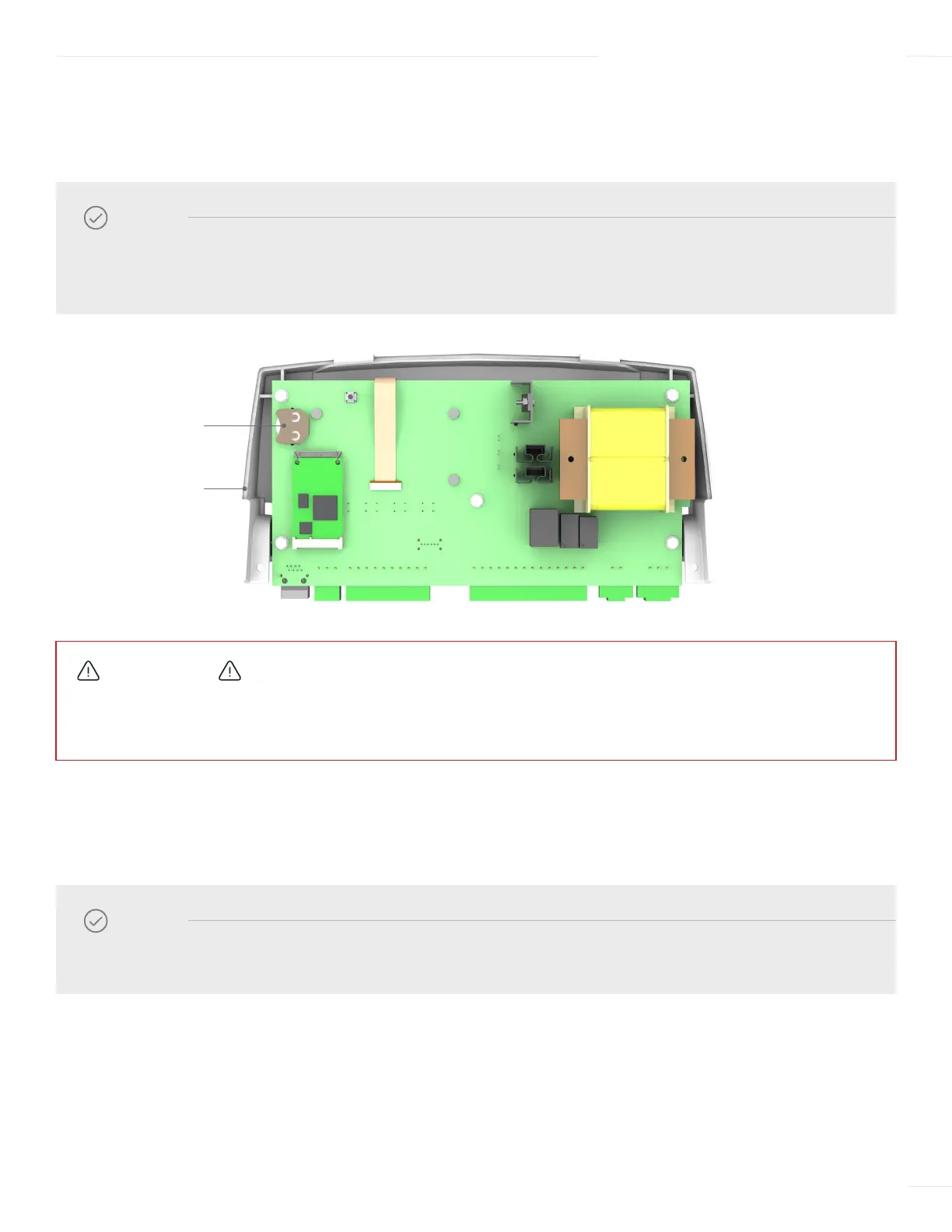

2 Turn the ETS-LT Control Module display module (1) over to reveal the battery (2) circuit board. Remove the

plastic tab to activate the battery.

3 Position the Display Module into the base and secure it in place using the middle screws removed in

Step 1 above.

4 Continue with “ETS-LT Optional Field Wiring”.

2

1

NOTE

The battery is a coin lithium battery (CR2032—Heat Timer P/N 020002–00) that is used to maintain the

control’s date and time during power outages. The battery can maintain the clock for up to a total of 100 days.

CAUTION

Do not remove the battery unless you plan to keep the control continuously powered. If the control

has no power, the battery will lose its charge in 100 days.

NOTE

Do not replace the Enclosure Wiring Cover until all wiring is completed.

Loading...

Loading...