57

Drive chain slack should be adjusted at your

Authorised Hero MotoCorp workshop as per

the specification.

NOTE

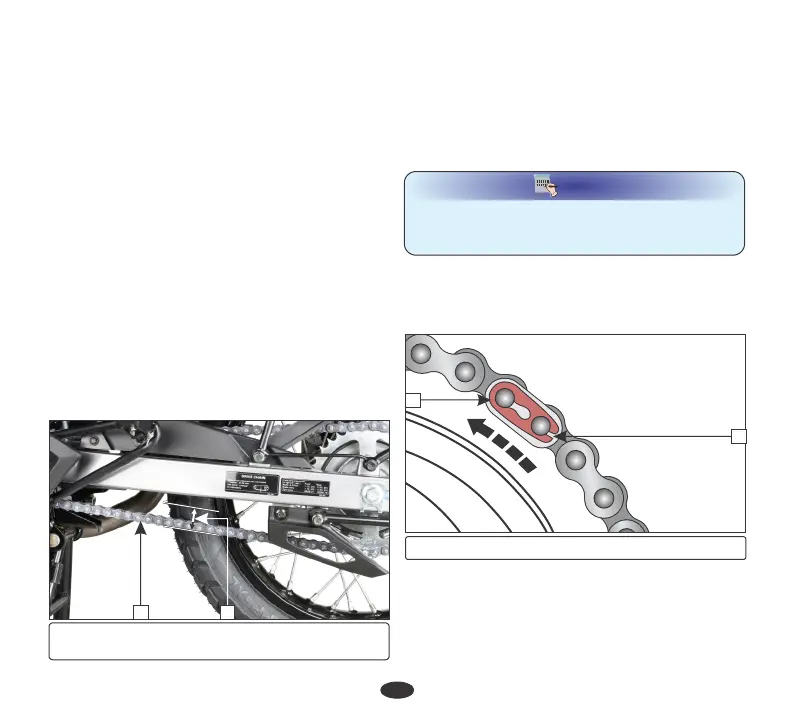

• Turn the chain to view chain lock plate (3).

Ensure that the chain lock plate open end

(4) is installed in the opposite direction of

the chain rotation.

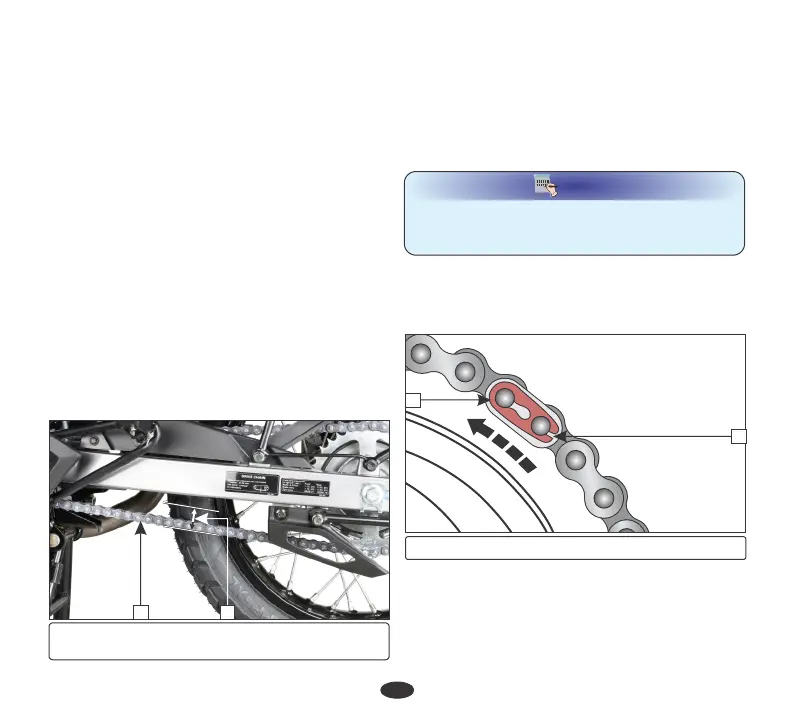

(1) Drive chain

(2) Drive chain slack: 30-35 mm

21

• Rotate the wheel and check the drive chain

slack. Repeat this procedure several times.

Drive chain slack should remain constant

(30-35 mm). If the chain is slack only in

certain sections, some links are kinked or

binding. Binding and kinking can be

eliminated by frequent lubrication.

(3) Chain lock plate (4) Open end

3

4

• Rotate the rear wheel slowly and inspect the

drive chain and sprockets for any of the

following conditions.

•

Loose pins

Drive chain

•

Damaged rollers

• Drive chain slack (2) should be checked in

the lower run midway between the

sprockets. Move the drive chain up and

down by hand and chain slack should be

adjusted to 30-35 mm vertical movement

by hand.

DRIVE CHAIN SLACKNESS

• Turn the engine “OFF”, park the vehicle on

its main stand and shift the transmission to

neutral.

Poor maintenance can cause premature wear

or damage to the drive chain and sprockets.

The service life of the drive chain depends

upon proper lubrication and adjustment.

Inspection

The drive chain (1) should be checked and

lubricated as part of the pre-ride inspection

(page 36). Under severe usage, or when the

vehicle is ridden in unusually dusty areas, more

frequent maintenance will be necessary.

Loading...

Loading...