54

VALVE CLEARANCE ADJUSTMENT

Excessive valve clearance will cause noise, and

little or no clearance will prevent the valve

from closing and cause valve damage and

power loss. Check valve clearance at the

specified intervals (page 45).

The checking or adjustment of valve clearance

should be performed while the engine is cold.

The clearance will change as the engine

temperature rises.

NOTE

•

If adjustment is required, adjust by loosening

the lock nut (8) and turning the adjusting

screw until there is a slight drag on the feeler

gauge.

•

Check the clearance by inserting the feeler

gauge (5) between the adjusting screw (6)

and valve stem (7).

This condition can be determined by moving

the rocker arms. If they are free, it is an

indication that the valves are closed and the

piston is in compression stroke. If they are

tight, the valves are open, rotate the flywheel

360° anticlockwise and realign the “T” mark

with the index mark.

Intake: 0.07 mm +0.01/-0.02

The adjustment must be made when the

piston is at top dead center and both the inlet

and exhaust valves are closed.

Standard clearance (cold condition)

Exhaust: 0.09 mm +0.01/-0.02

41

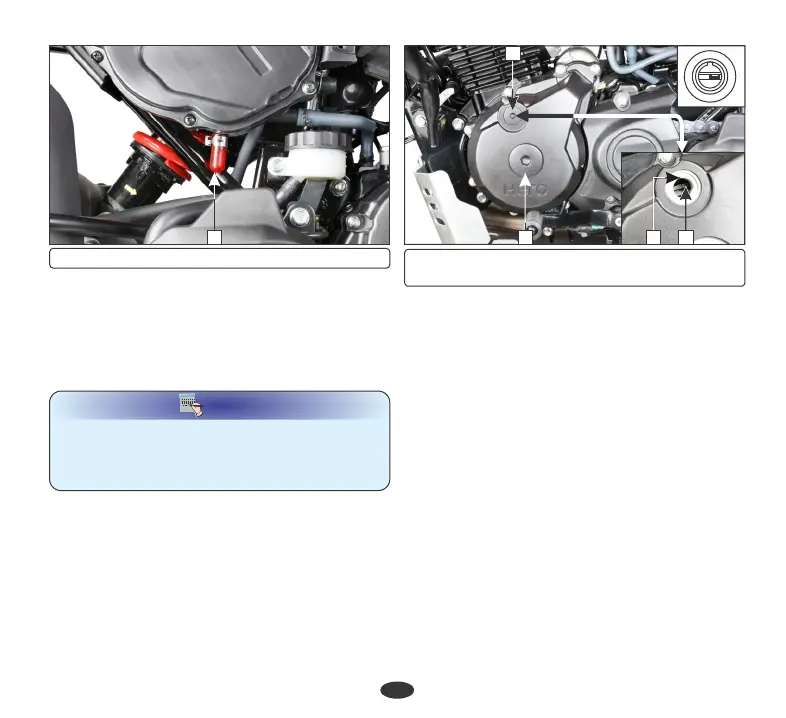

(3) 'T' mark (4) Index mark

(1) Crankshaft hole cap (2) Timing hole cap

3

2

• Rotate the flywheel anticlockwise until the

“T” mark (3) on the flywheel coincides with

the index mark (4) on the left crankcase

cover. In this position the piston will either

be on the compression or exhaust stroke.

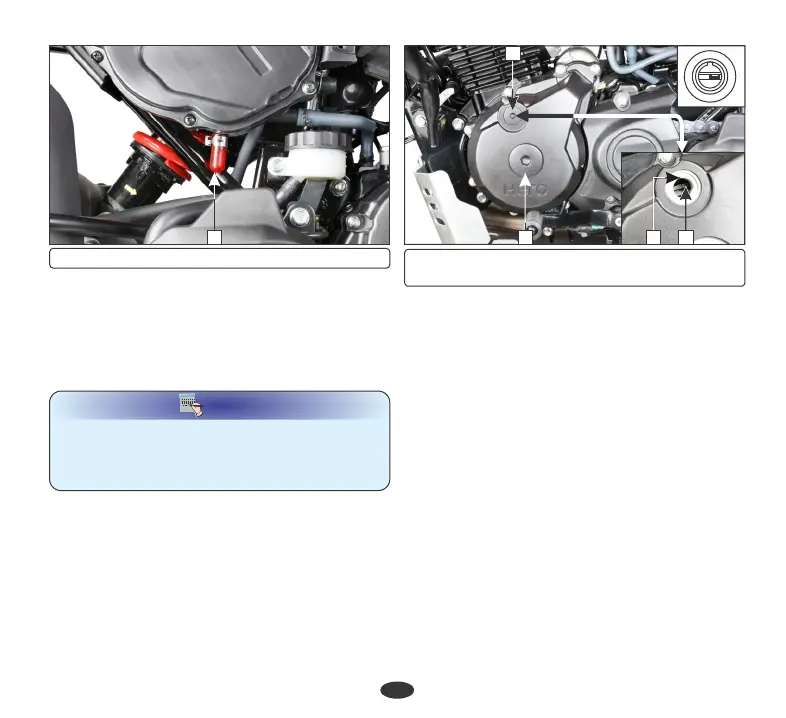

• Remove the fuel tank.

• Remove the cylinder head cover.

• Remove the crankshaft hole cap (1) and

timing hole cap (2).

(1) Drain tube

1

Loading...

Loading...