45

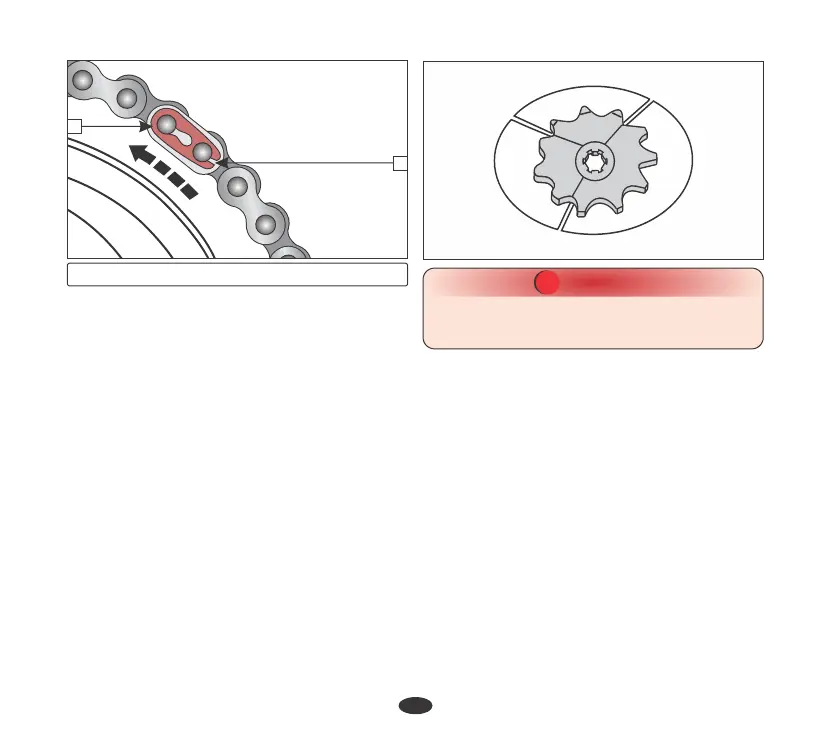

(3) Chain lock plate (4) Open end

3

4

•

Damaged or missing O-rings.

If the drive chain or sprockets are excessively

worn or damaged, they should be replaced.

•

Loose pins

•

Kinked or binding links

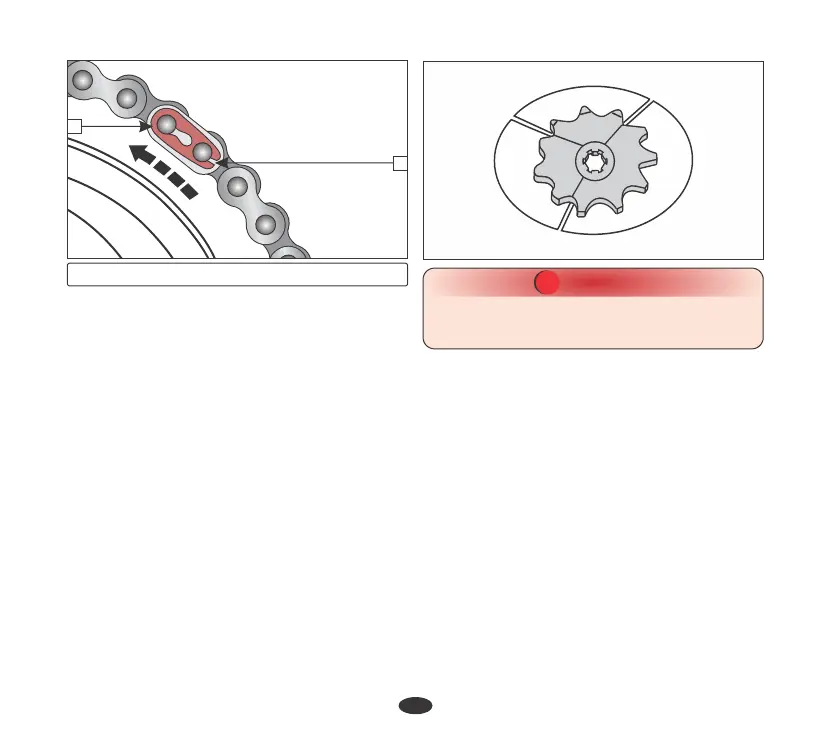

Sprockets

•

Excessive wear

If the drive chain has damaged rollers, loose

links or missing O-rings, replace it. If the

chain is dry or rusted, it should be lubricated.

•

Dry or rusted links

Lubricate the chain if the links are kinked or

binding. If the problem is not solved after

lubrication, replace the chain.

•

Improper adjustment

•

Excessively worn teeth

•

Broken or damaged teeth.

Drive chain

•

Damaged rollers

c

o

k

r

e

p

t

S

T

e

n

r

e

o

t

h

W

c

o

r

p

k

e

S

t

l

T

a

e

m

e

r

t

o

h

N

o

r

p

c

S

k

d

e

e

t

g

T

a

e

e

m

t

a

h

D

CAUTION

!!

Always replace the drive chain and sprockets

as a set. Otherwise the new part will wear

prematurely.

Adjustment

Drive chain slack should be checked and

adjusted, if necessary at every 000 km.1

• Loosen the drive chain lock nut (2).

• Loosen the rear axle nut (1).

When operated at sustained high speeds or

under conditions of frequent rapid

acceleration, the chain may require more

frequent adjustments.

• Park the vehicle on its main stand with the

transmission in neutral and the ignition

switch in “OFF” position.

• Turn the adjusting nut (3) in an equal

number of turns until the correct drive chain

slack is obtained. Turn the adjusting nut

clockwise to decrease the slack or

If the drive chain requires adjustment, follow

the procedures below:

Loading...

Loading...