Appendix 7 Unstable Measured Values

A17

Appendix

(4) Wider/Thicker measurement targets

When the measurement target is wide or thick like a

board or block, or when using a current sensing

resistor (shunt resistor) of less than 100 m, it will

be difficult to measure accurately using Pin Type

Leads or Clip Type Leads. By using such measure-

ment probes, there may be considerable fluctuation

of the measured value due to contact pressure or

contact angle. For example, when measuring a

W300 × L370 × t0.4 mm metal board, the measured

values are fairly different, even if measuring the

same points, as shown below:

• 0.2mm pitch Pin type lead: 1.1 m

• 0.5mm pitch Pin type lead: 0.92 to 0.97 m

• Model L2101 Clip Type Lead: 0.85 to 0.95 m

Additionally, since the resistance values of current sensing resistors assume mounting on a

printed circuit board, the desired resistance value cannot be obtained if the resistor’s termi-

nals are measured using a pin-type lead.

This does not depend on the contact resistance between

probe

s and the measurement tar-

get, but on the current distribution on the measurement target.

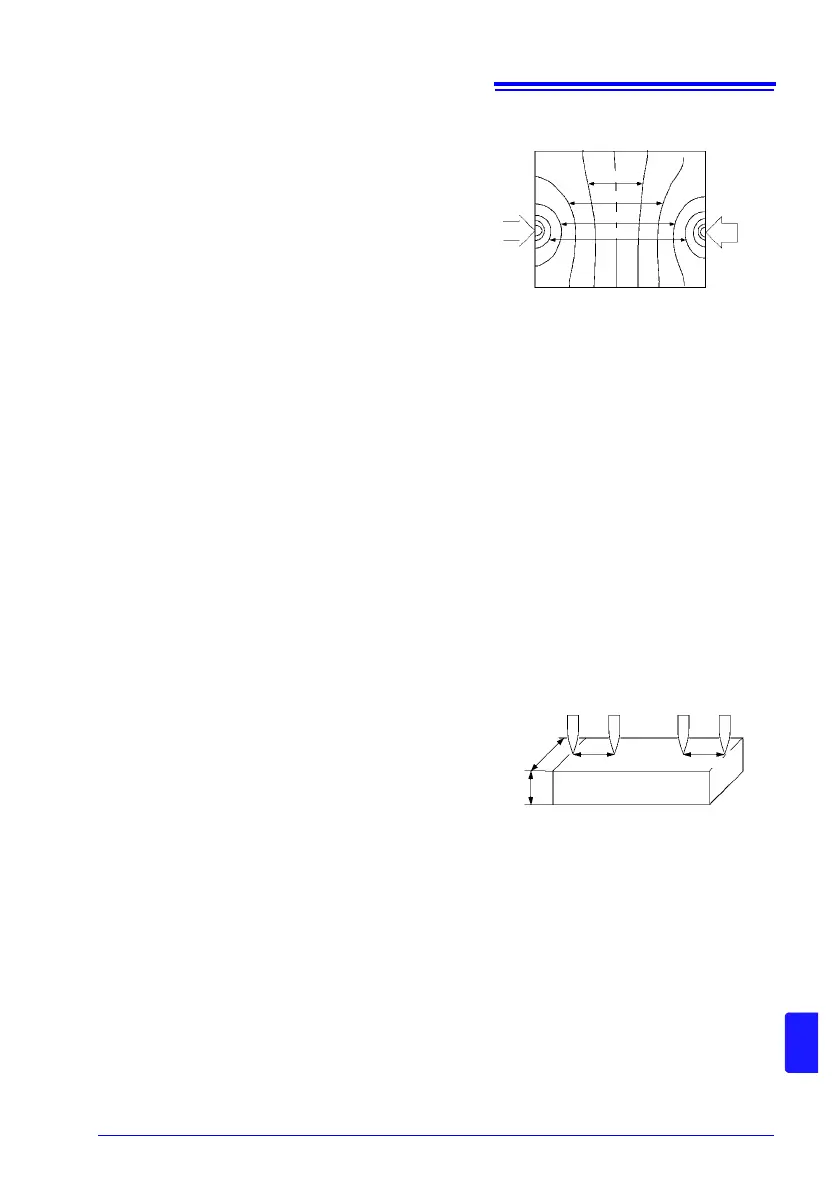

Fig. 10 is an example of plotting equivalent electric potential lines of a metal board. Similar

to the relation between atmospheric pressure distribution and wind on a weather forecast

diagram, current density is higher in locations where the equivalent electric potential lines

are narrowly spaced, and lower in locations where they are widely spaced. Through this

example, it is shown that the electric potential slope is larger around current applying

points. This phenomenon is caused by high current density while current expands on the

metal board. Due to this phenomenon, measured values should be rather different, even if

the connected position difference is quite slight, in case connecting voltage detection termi-

nals (of measurement

probe

s) near current applying points.

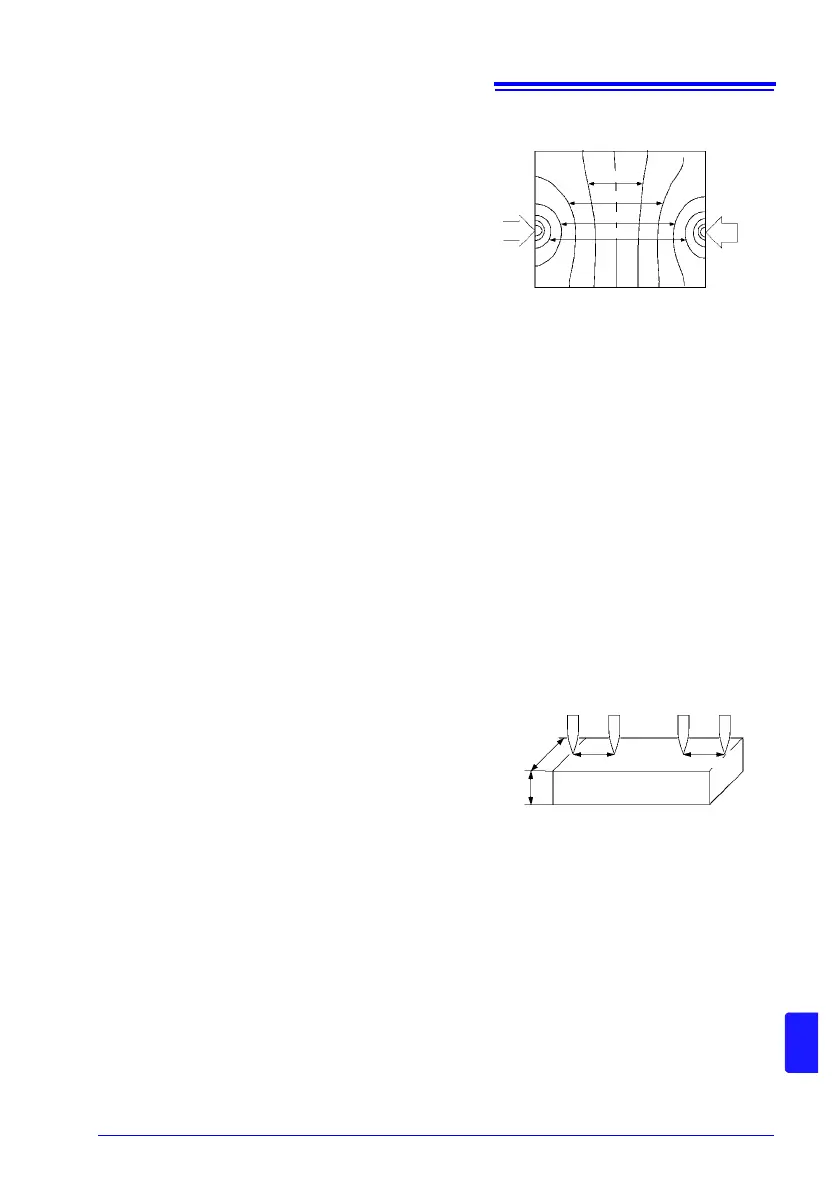

It is known that such effects can be minimized by

detecting the voltage within the space between the

current contact points.

Generally, if the probes are inside by a margin that is

at least three times the measurement target’s width

(W) or thickness (t), current distribution may be con-

sidered uniform.

As shown in Fig. 11, SENSE leads should be 3W or

3t mm or more inside from the SOURCE leads.

(5) Unstable Temperature of the measurement target

Copper wire resistance has a temperature coefficient of about 0.4%/°C. Just holding a cop-

per wire in the hand raises its temperature, causing its resistance to be increased as well.

When the hand is removed from the wire, temperature and resistance decrease.

Windings are more susceptible to temperature increase immediately after treatment with

varnish, so the resistance tends to be relatively high.

When the temperature of the measurement target and probe differ, thermal EMFs will be

generated, causing an error. Allow the measurement target to adjust to room temperature

as much as possible prior to measurement.

Current

Applying

Figure 10. Equipotential lines on a metal

board (W300 × L370 × t0.4 mm)

∗ Applying 1 A current on points on edges

and plotting equivalent electric potential

lines at each 50 V level

0.1m

0.2m

0.3m

0.4m

3W, 3t or more 3W, 3t or more

Figure 11. Probe Positions on

Wider/Thicker measurement target

SOURCE B SENSE B SENSE A SOURCE A

W

t

Loading...

Loading...