Appendix

13

13.2. Help with problems

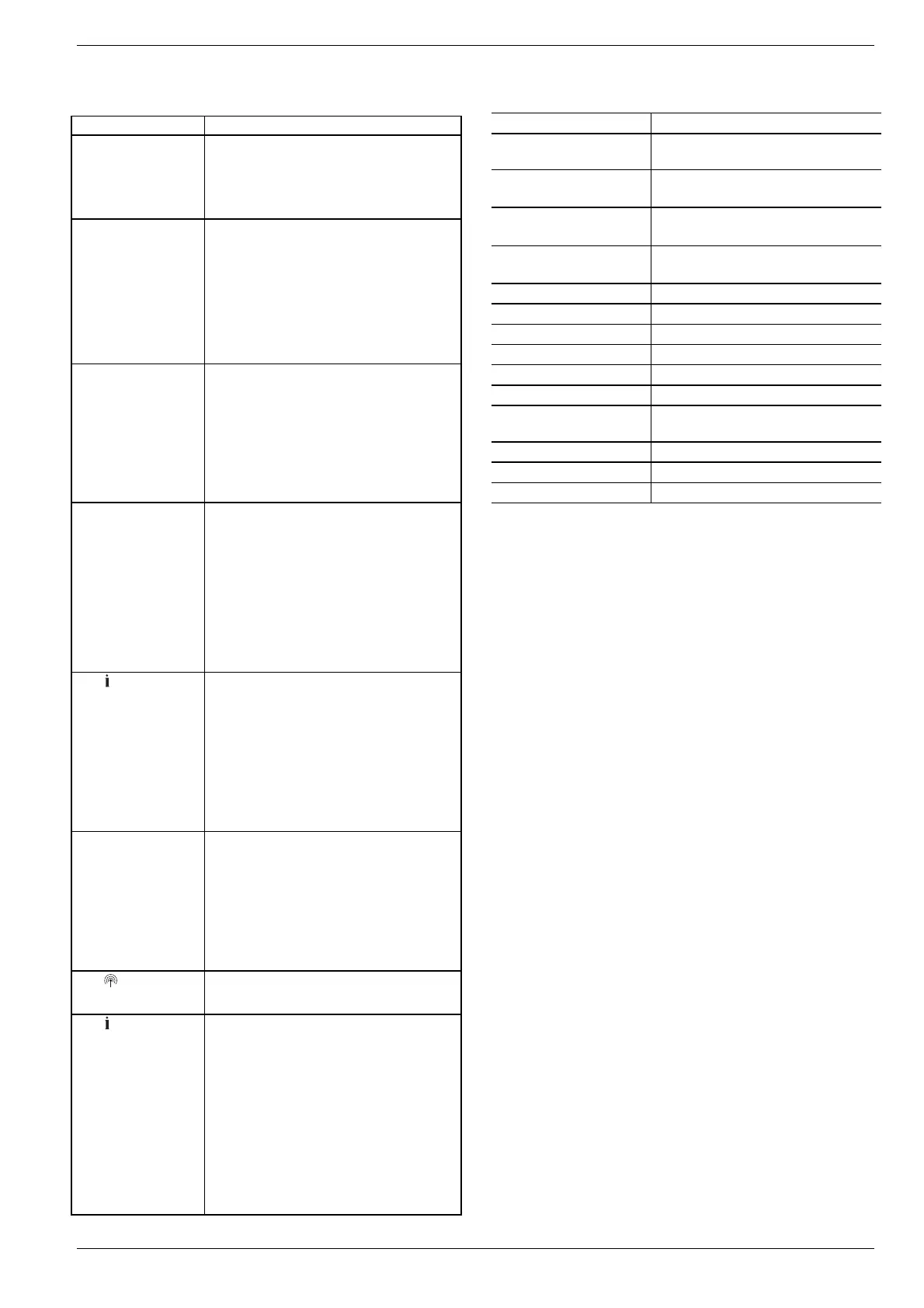

Problem Cause/Solution

Power LED does

not light up when

the power is

switched on.

Mains voltage not connected.

► Check voltage of electrical outlet.

► Check fuse at underfloor heating

controller.

LEDs 1...8 of the

zones do not illumi-

nate green continu-

ously during start-

up.

The room name is not assigned.

► Check whether or not the Hometronic

Manager is installed.

► Check whether or not a room name is

assigned to zone.

► Check the antenna connection.

► Reassign the zone, if applicable.

LEDs 1...8 of the

zones do not illumi-

nate red continu-

ously during start-

up.

The setpoint adjuster cannot be as-

signed.

► Check whether or not batteries in

setpoint adjuster are inserted prop-

erly.

► Check wireless connection.

► Check the antenna connection.

Rooms are not

heated/cooled.

► Check heating and inlet temperature.

► Check adaptation to thermal actuator

(see Page 6).

► Check fuse of underfloor heating

controller.

If fuse is defective:

► Check actuators for short circuit.

► Change the fuse.

The LED lights up

red after commis-

sioning.

There is a fault in one of the tempera-

ture zones (see Page 12).

► Check wireless connection.

► Check the antenna connection.

► Check whether or not zone is as-

signed correctly.

► Check the batteries of the allocated

devices.

Room controlled

incorrectly.

► Check whether or not adjustment dial

of setpoint adjuster is at position 0.

► Check whether or not the adjusting

ring can be turned between -12 and

+12 with the housing cover removed.

► Check whether or not a setpoint

adjuster is assigned to room.

The LED flashes

rapidly.

No device installed.

► Install the devices again.

The LED flashes.

No antenna connected or antenna

defective.

► Check whether or not an antenna is

connected.

If no antenna is connected:

► Connect an antenna.

If an antenna is connected:

► Check the antenna connection.

► If applicable, replace the antenna by

a new one.

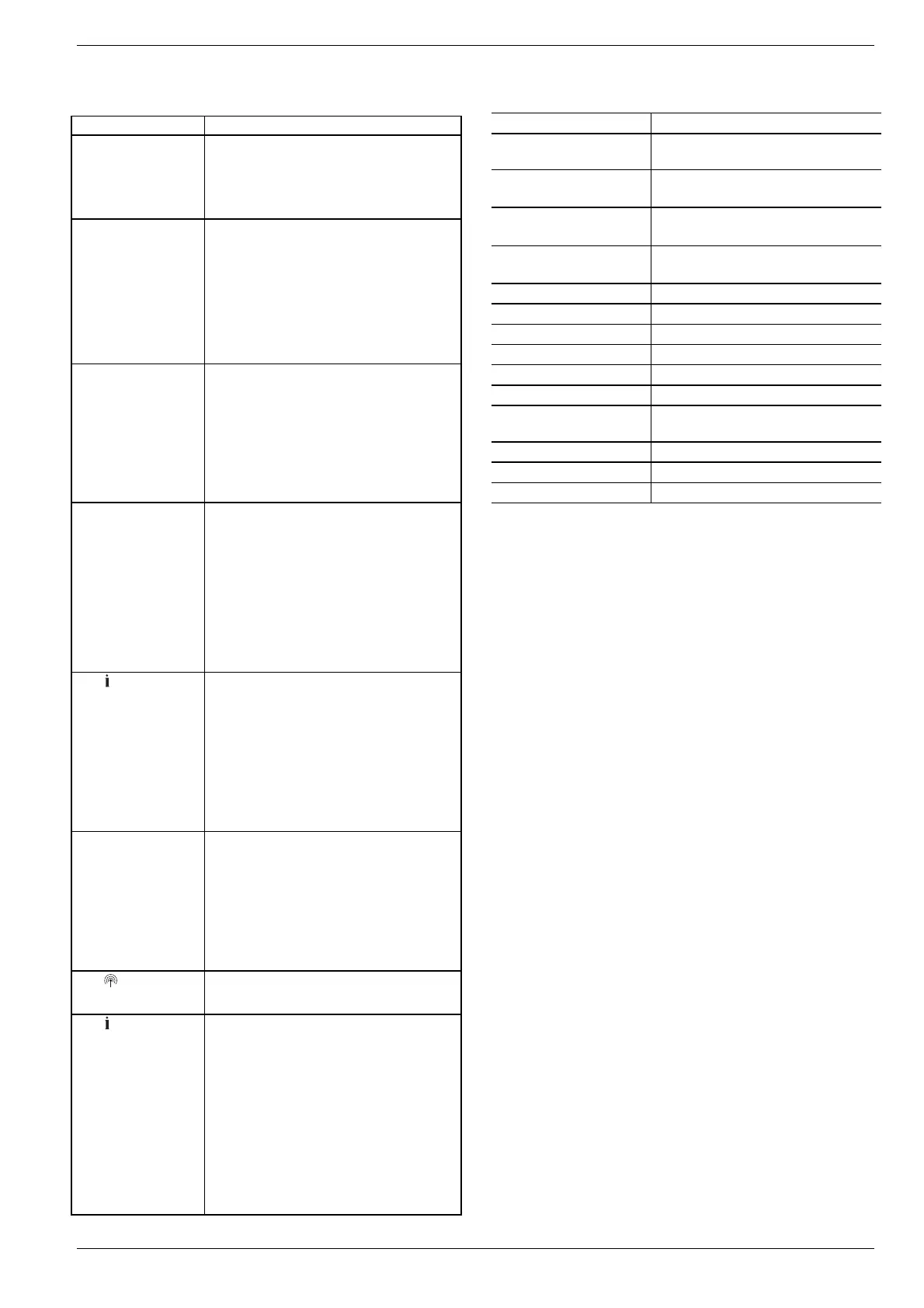

13.3. Technical data

Input/Output voltage 230 V AC, 50 Hz

Power consumption

Max. 1750 VA with connected pump

(max. 6 A)

Pump relay

Switching contact 230 V AC, max.

6 A (not floating) ; cosϕ ≥ 0.7

Boiler feedback relay

42 V AC; 1 V < U ≅ 42 V;

1 mA < I ≅ 100 mA; cosϕ = 1

Thermal actuators

2.7 A max. for 1 sec; 200 mA;

cosϕ ≥ 0.95

Ambient temperature 0 to 50°C

Storage temperature -20 to +70°C

Humidity 5 to 93 % relative humidity

Frequency 868.3 MHz (transmitter/receiver)

Dimensions 350x82x52 mm (WxHxD)

Weight 1 kg

Fuse

Ceramic fuse 5x20 mm, 230 V AC;

2.5 A; fast

Material ABS

Degree of protection IP30

Fire class V0

13.4. Device and function definition in

accordance with EN 60730-1

• Purpose of the device is temperature controlling

• Device fulfils Protection class 1, EN60730-1,

EN60730-2-9

• Independently installable electronic control system with

fixed installation

• Type of action is Type 1.B (pump relay) and Type 1.C

(thermal actuator)

• Temperature for ball-thrust hardness test for housing

components 75 °C and for live parts such as, for exam-

ple, terminals 125 °C

• EMC emitted interference test at 230 V AC +10/-15 %,

1750 VA maximum

• Pollution severity is 2

• Rated voltage is 4000 V (corresponding to Overvoltage

category III)

• Software class is A

Loading...

Loading...