Revision 10 ST 800 SmartLine Pressure Transmitters User’s Manual Page 5

2 Application Design

2.1 Overview

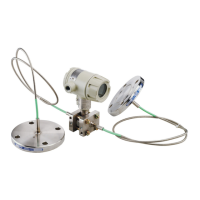

This section discusses the considerations involved with deploying a Honeywell ST 800 SmartLine

Pressure Transmitter in a process system. The following areas are covered:

Safety

Input and output data

Reliability

Environmental limits

Installation considerations

Operation and maintenance\

Repair and replacement

2.2 Safety

2.2.1 Accuracy

The ST 800 SmartLine Pressure Transmitter (Transmitter) measures the gauge, differential, or

absolute pressure of a process and reports the measurement to a receiving device.

2.2.2 Diagnostic Messages

Transmitter standard diagnostics are reported in the two basic categories listed in Table 3. Problems

detected as critical diagnostics drive the analog output to the programmed burnout level. Problems

detected as non-critical diagnostics may affect performance without driving the analog output to the

programmed burnout level. Informational messages (not listed in Table 3) report various Transmitter

status or setting conditions. The messages listed in Table 3 are specific to the Transmitter, exclusive

of those associated with HART and DE protocols. HART and DE diagnostic messages are listed and

described in the ST 800 SmartLine Pressure Transmitter HART/DE Option User Manual, document

number 34-ST-25-38.

Table 3 - ST 800 Standard Diagnostics Messages

Critical Diagnostics (Failure

Conditions)

Non-Critical Diagnostics (Warning Conditions)

Electronic Module DAC Failure

URV Set Err. Span Config

Button

Electronic Module Diag Failure

LRV Set Err. Zero Config

Button

Meter Body Critical Failure

Meter Body Excess Correct

Meter Body Unreliable Comm

Loading...

Loading...