Page 18 ST 800 SmartLine Pressure Transmitters User’s Manual Revision 10

3.5.2 Suggestions for Transmitter Location

Suggests connections based on what is being processed by the system.

Table 6 – Suggested Connection Locations

The condensate drains away from the Transmitter.

Below but near the elevation of

the process connection.

This minimizes that static head effect of the

condensate.

Level with or above the process

connection.

This requires a siphon to protect. the Transmitter from

process steam. The siphon retains water as a fill fluid.

1. For liquid or steam, the piping should slope a minimum of 25.4 mm (1 inch) per 305 mm (1 foot).

2. Slope the piping down toward the Transmitter if it is below the process connection to allow

the bubbles to rise back into the piping through the liquid.

3. If the transmitter is located above the process connection, the piping should rise vertically

above the Transmitter. In this case, slope down toward the flow line with a vent valve at the

high point.

4. For gas measurement, use a condensate leg and drain at the low point (freeze protection may

be required here).

ATTENTION Care must be taken when installing transmitters on hot processes.

The operating temperature limits for the device (as outlined in Table 5) must not be

exceeded. Impulse piping may be used to reduce the temperature of the process that

comes into contact with the transmitter meter body. As a general rule there is a 56C drop

(100 F) in the temperature of the process for every foot of ½ inch uninsulated piping.

3.5.3 General Piping Guidelines

When measuring fluids that contain suspended solids, install permanent valves at regular

intervals to blow-down piping.

Blow-down all lines on new installations with compressed air or steam, and flush them with

process fluids (where possible) before connecting these lines to the Transmitter Meter Body.

Verify that the valves in the blow-down lines are closed tightly after the initial blow-down

procedure and each maintenance procedure thereafter.

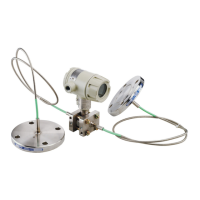

3.5.4 Procedure to Install Flange Adapters

The following procedure provides the steps for removing and replacing an optional flange adapter on

the process head.

This procedure does not require that the Meter Body be removed from the Electronics

Housing. If flange adapters are being replaced with parts from other kits (for example,

process heads), follow the procedures for the kits and incorporate the following procedure.

NOTE: The threaded hole in each Flange Adapter is offset from center. To ensure proper

orientation for re-assembly, note the orientation of the offset relative to each Process Head

before removing any adapter.

Loading...

Loading...