Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Troubleshooting

HD3N-TC Series Inverter User Manual V1.0 ―69―

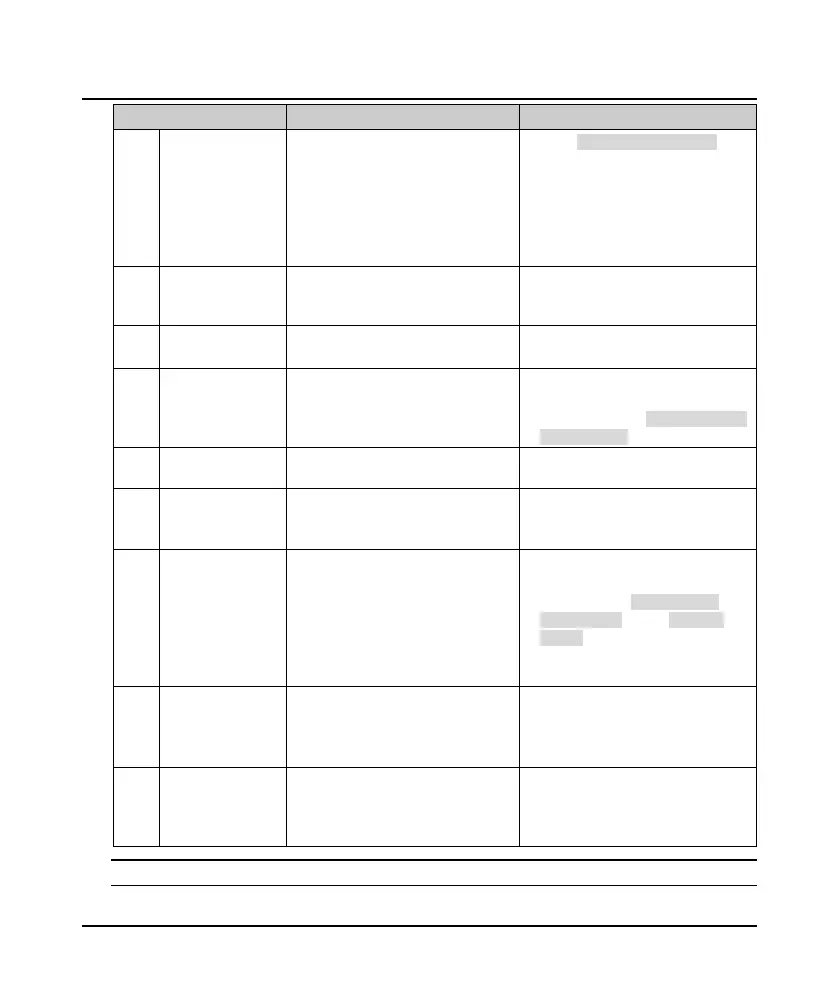

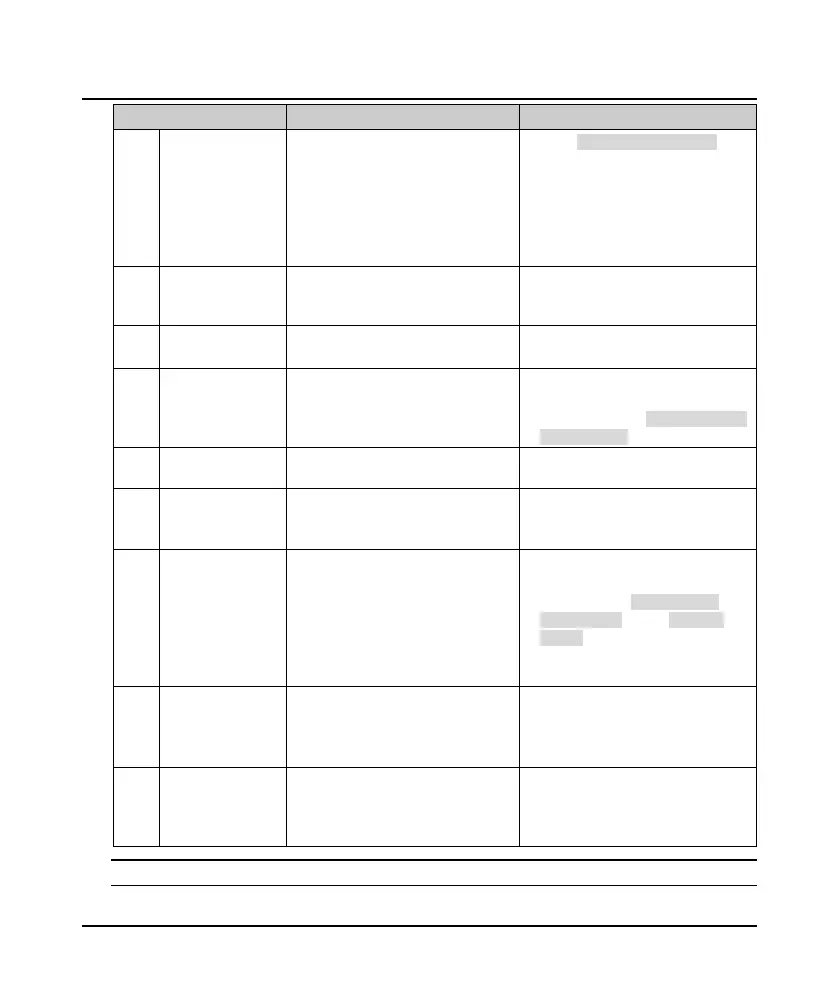

Fault Fault reasons Counter-measures

E0019

Motor overload

• Improper setting of V/f curve

• Mains supply voltage is too low

• Normal motor runs for a long time

with heavy load at low speed

• Motor locked-rotor or overload

• Adjust V/f curve (F09.00 - F09.06)

• Check the power input

• Use special motor if the motor needs

to operate for a long time with heavy

load

• Check the load and mechanical

transmission devices

E0021

Read / Write fault of

control board

EEPROM

• Memory circuit fault of control board

EEPROM

• Contact the supplier for repairing

E0022

Read / Write fault of

keypad EEPROM

• Memory circuit fault of keypad

EEPROM

• Replace the keypad

• Contact the supplier for repairing

E0023

Faulty setting of

parameters

• The power rating between motor and

inverter is too different

• Improper setting of motor

parameters

• Select an inverter with suitable power

rating

• Set correct value of motor parameters

(F08.00 - F08.04)

E0024

Fault of external

equipment

• Fault terminal of external equipment

operates

• Check external equipment

E0028

SCI communication

timeout

• Connection fault of Communication

cable

• Disconnected or not well connected

• Check the connection

E0029

SCI communication

error

• Connection fault of communication

cable

• Disconnected or not well connected

• Communication setting error

• Communication data error

• Check the connection

• Check the connection

• Correctly set the communication

format (F17.00) and the baud rate

(F17.01)

• Send the data according to MODBUS

protocol

E0030

Brake fault

• Brake contactor does not act

• Brake contactor is damaged

• Brake contactor is nornally run, but

there is no feedback signal

• Check wiring of brake

• Replace brake contactor

• Check feedback wiring

E0032

Brake releasing is

abnormal

• Detection time for brake releasing

abnormal is too short

• Brake releasing current/torque is too

high

• Properly set detection time for brake

releasing

• Adjust brake releasing current/torque

Note:

E0022 does not affect the normal use of inverter.

Loading...

Loading...