I.30

Part. N. 8000 H0368 (09-2008)

FRONT SUSPENSION

Issues - Possible Causes - Solutions

This section describes some of the issues that may arise during the working life of the fork.

For each issue listed, a possible cause is identified and a possible solution is given. Always consult this table before working on the fork.

ISSUE CAUSE SOLUTION

Oil leaking from the sealing ring 1. Worn sealing ring 1. Replace the sealing ring

2. Scratched stanchion tube 2. Replace the stanchion tube and the

sealing ring

3. Dirty sealing ring 3. Replace the sealing ring,the dust

seal and the oil

Oil leaking from the bottom of the fork leg 1. O-ring seal of the rebound 1. Replace O-ring

screw adjuster damaged

2. Rebound adjuster loose

2. Tighten the rebound adjuster

Loss of sensitivity 1. Sliding bushes worn 1. Replace the sliding bushings

2. Old oil 2. Change the oil

Fork legs not sliding properly 1. Fork legs not aligned correctly 1. Replace any bent or

damaged parts

The fork does not react 1. The pin inside the rod is stuck 1. Clean or replace rod

to adjustment variations 2. The adjustment screw is stuck 2. Take off and clean adjustment

screw

3. Impurities in the oil 3.

Change the oil making sure the

forks ’ inside components

are properly cleaned

4. Valves are blocked with impurities 4.

Change the oil making sure the

forks ’ inside components

are properly cleaned

Fork is too smooth 1. Oil level too low 1. Re-establish correct oil level

with any adjustment 2. Oil viscosity too low 2. Replace the oil with a higher

viscosity one

3. Too soft or damaged spring 3. Replace the spring

Fork is too stiff 1. Oil level too high 1. Re-establish correct oil level

with any adjustment 2. Oil viscosity too high 2. Replace the oil with a higher

viscosity one

3. Too hard spring 3. Replace the spring

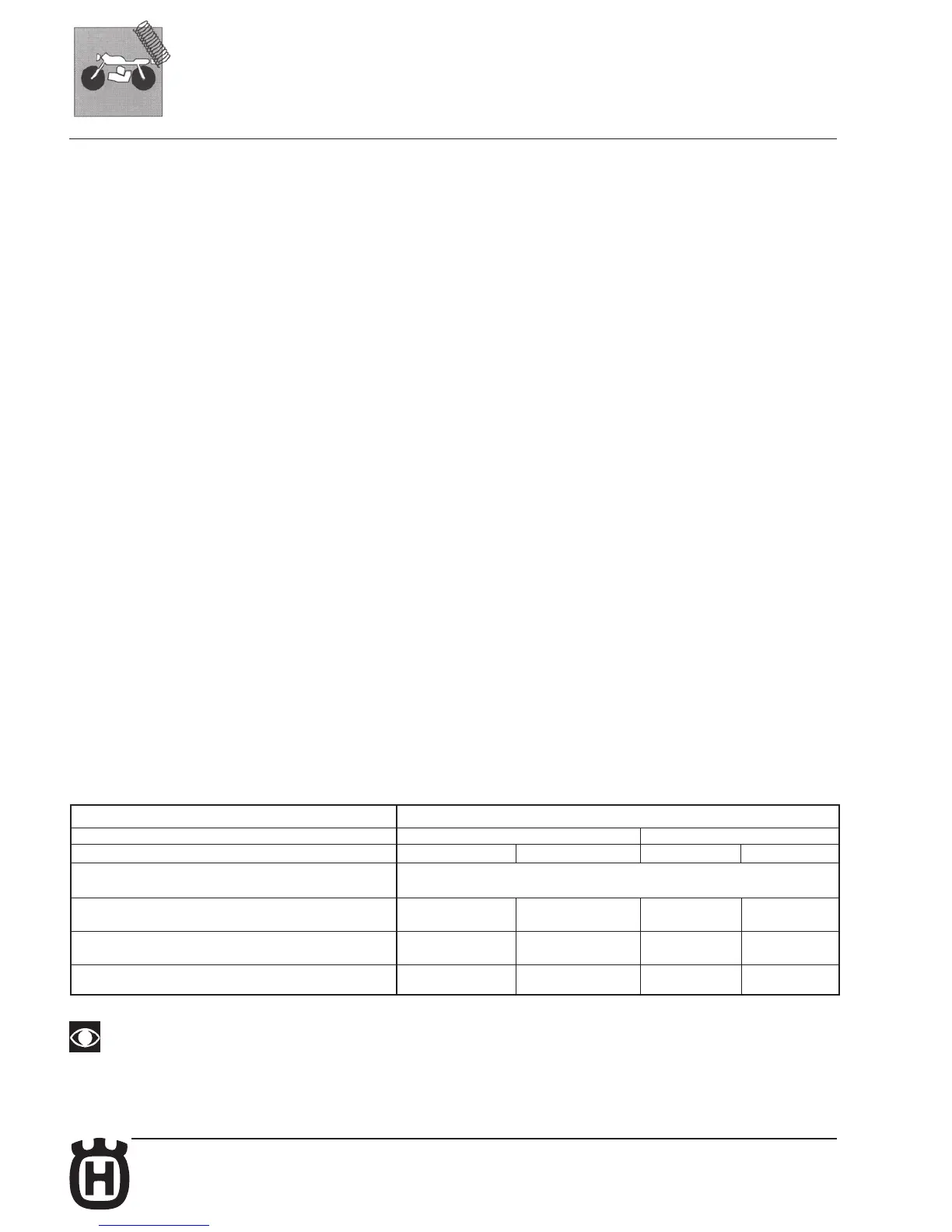

Periodical Maintenance Table

Use

Intense Normal

Off-road Road Off-road Road

Check that screws are tightened to required torque Before every ride

Clean the dust seal After every race After every race After every ride After every ride

Change the oil 6 hours 20 hours 30 hours 60 hours

Replace the sealing rings 6 hours 20 hours 30 hours 60 hours

If the fork is used on mudded or sandy grounds, the maintenance operations shall be carried out more frequently 30% .

Loading...

Loading...